INNOVATIV AUẞENROLLLADE-SYSTEMWIN SCREEN

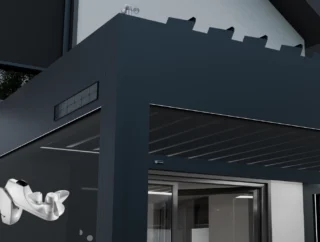

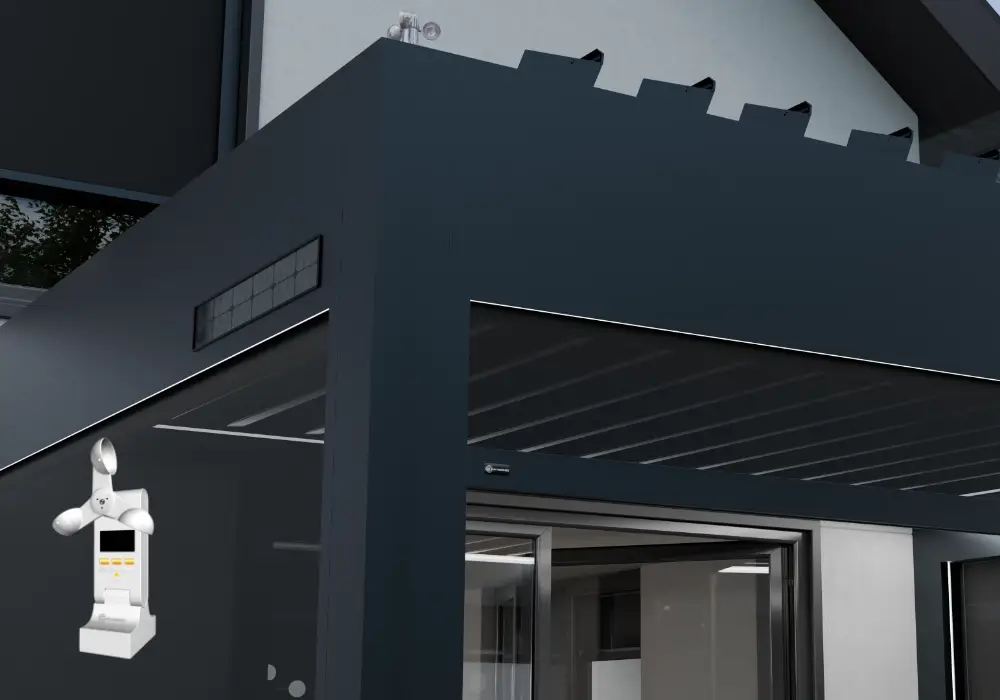

Modernes System der Außenrollläden ZIP WIN SCREEN

Außenrollläden WIN SCREEN von SUN WINNER sind eine Innovation, die den Weltmarkt für Sonnenschutzprodukte revolutioniert.

WIN SCREEN ist ein eigenes, innovatives und das fortschrittlichste Außenrollladensystem der Welt, das vollständig in Polen entworfen und produziert wurde.

Die darin enthaltenen Lösungen sind in Konkurrenzsystemen nicht verfügbar und machen unser Produkt in der Sonnenschutzbranche konkurrenzlos.

Wir bieten die größten Abmessungen in Europa für WIN SCREEN-Rollläden an, mit den maximalen Maßen:

7000 mm x 3400 mm (23,8 m²)

5400 mm x 6000 mm (32,4 m²)

VIDEO

MODELLE DER WIN SCREEN SYSTEME

SYSTEMBESCHREIBUNG

SYSTEMMERKMALE

SYSTEMBESCHREIBUNG

SYSTEMMERKMALE

SYSTEMBESCHREIBUNG

SYSTEMMERKMALE

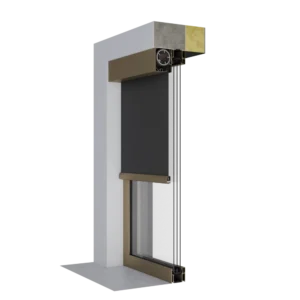

WIN SCREEN ROLLLADENSYSTEM

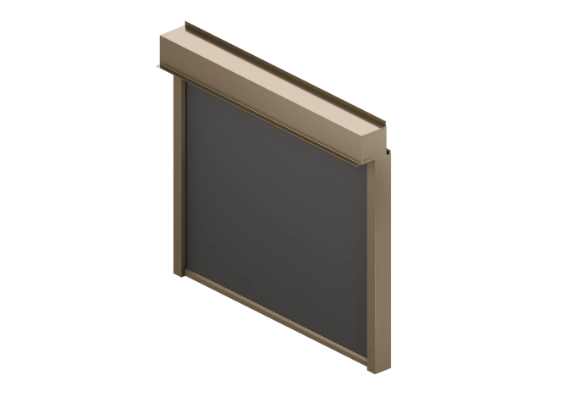

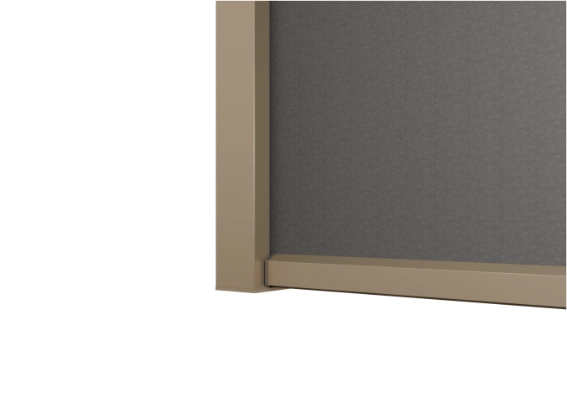

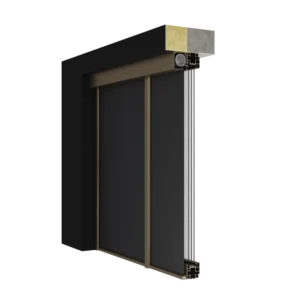

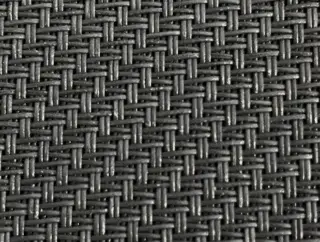

Außenrollläden WIN SCREEN ZIP sind fortschrittliche Fensterbeschattungssysteme, die hauptsächlich an der Außenseite von Gebäuden montiert werden. Sie zeichnen sich durch den Einsatz eines speziellen Gewebes anstelle eines herkömmlichen Rollladenpanzers aus. Das Gewebe ist strapazierfähig, witterungsbeständig und erfüllt hervorragend sowohl eine Schutz- als auch eine dekorative Funktion.

FUNKTIONALITÄT

Rollläden bieten einen effektiven Schutz vor Sonneneinstrahlung und ermöglichen gleichzeitig die Kontrolle des Lichteinfalls im Innenraum. Durch den Einsatz von Geweben mit unterschiedlichem Öffnungsfaktor – z. B. 1 %, 4 %, 5 % oder 14 % – bleibt die Sicht nach außen erhalten, was den Kontakt zur Umgebung ermöglicht und gleichzeitig den Einblick ins Gebäudeinnere reduziert. Blackout-Gewebe sorgen für vollständige Privatsphäre und 100 % Verdunkelung, während Fenster mit CRISTAL-Folie ideal für Räume mit hohem Tageslichtbedarf geeignet sind.

Das WIN SCREEN-Rollladensystem verbessert zudem die Energieeffizienz, indem es im Sommer die Aufheizung der Räume reduziert und im Winter Wärmeverluste minimiert. WIN SCREEN-Rollläden schützen außerdem vor Wind, Regen und anderen Witterungseinflüssen und erhöhen den akustischen Komfort durch die Reduzierung von Außengeräuschen. Unser innovatives Gewebe-Schweißverfahren und der optimierte ZIP-Reißverschluss sorgen dafür, dass unsere Rollläden selbst stärkstem Wind standhalten. Die optionale Wetterautomatik gewährleistet zusätzliche Sicherheit für das gesamte System.

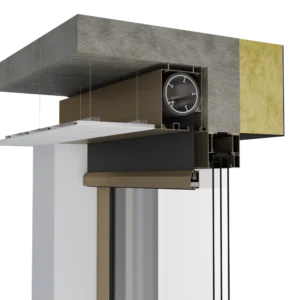

AUFBAU UND FUNKTIONSWEISE

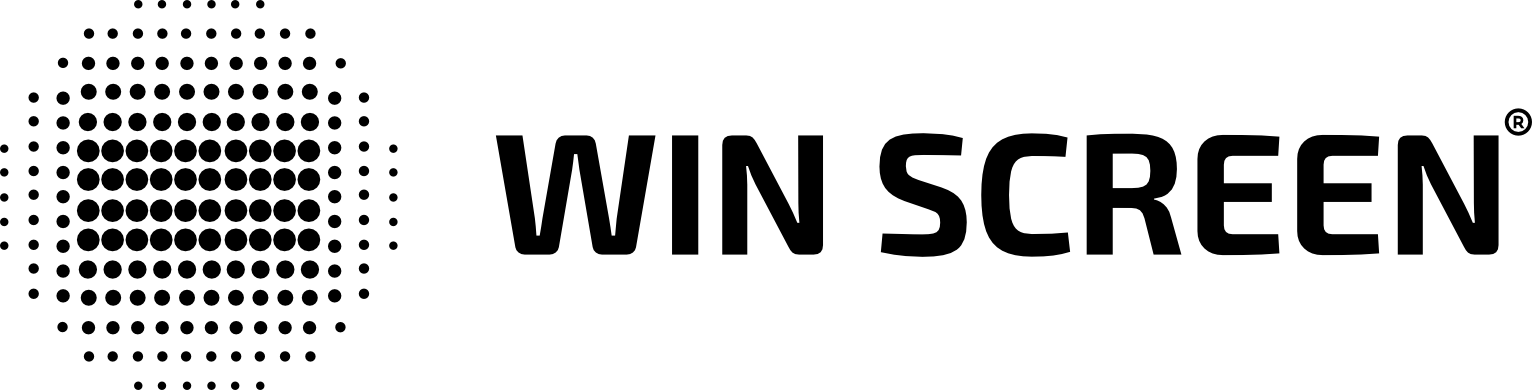

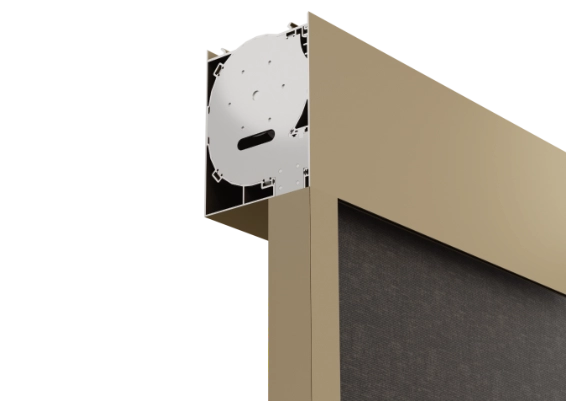

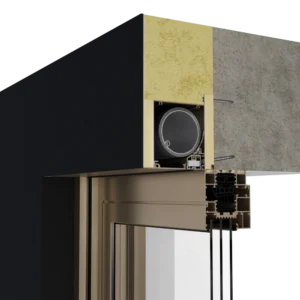

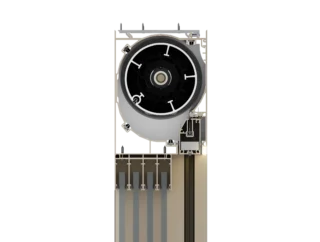

Das zentrale Element des WIN SCREEN-Rollladens ist das technische Gewebe aus Polyester- oder Glasfasern, das mit einer PVC-Beschichtung versehen ist. Das Gewebe wird in seitlichen Führungsschienen geführt, was für Stabilität selbst bei starkem Wind sorgt. In ZIP-Systemen wird zusätzlich ein spezieller Reißverschluss im Gewebe verwendet, der ein Herausrutschen aus den Führungsschienen verhindert. Der Aufrollmechanismus erfolgt über eine Wickelwelle, die sich innerhalb der Kassette befindet. WIN SCREEN-Rollläden werden mittels Elektromotor aufgerollt, was eine Fernsteuerung oder die Integration in ein Smart-Home-System ermöglicht.

ANWENDUNG

WIN SCREEN-Rollläden eignen sich hervorragend sowohl für Wohngebäude als auch für gewerbliche Objekte. Dank ihres modernen Designs und der großen Farbvielfalt der Gewebe stellen sie eine ästhetische und funktionale Lösung dar. Sie können an der Fassade, in Fensterlaibungen oder als freihängende Ausführung montiert werden und passen sich flexibel den Anforderungen der Nutzer an.

VORTEILE DES SYSTEMS

REDUZIERUNG DER KLIMATISIERUNGS- UND HEIZKOSTEN DES GEBÄUDES

AUTOMATISIERUNG UND INTEGRATION IN SMART-HOME-SYSTEME

SONNENSCHUTZEIGENSCHAFTEN

SCHUTZ VOR STARKEM WIND

INSEKTENSCHUTZ

SICHTEIGENSCHAFTEN DER GEWEBE

GROSSE ABMESSUNGEN BEI KOMPAKTEM SYSTEMAUFBAU

GROSSE AUSWAHL AN SCREEN-GEWEBEN UND FARBVARIANTEN DER ROLLLADENKOMPONENTEN

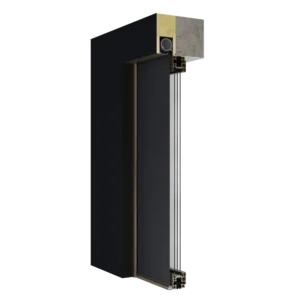

MODERNES UND MINIMALISTISCHES DESIGN

ADAPTIVE SYSTEME

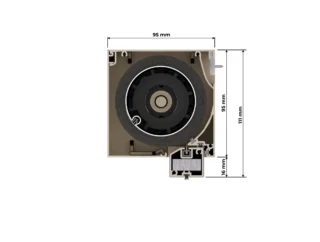

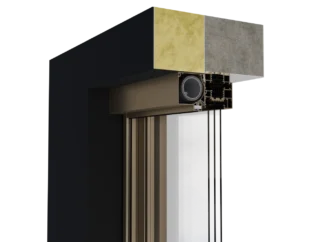

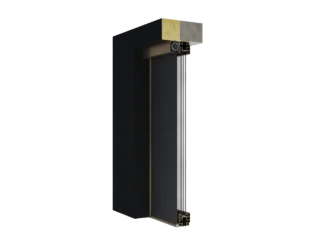

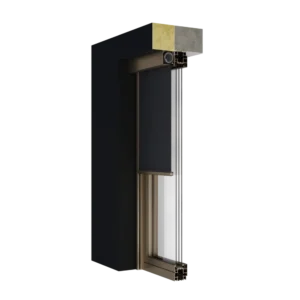

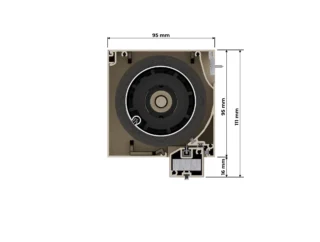

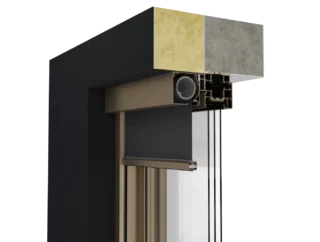

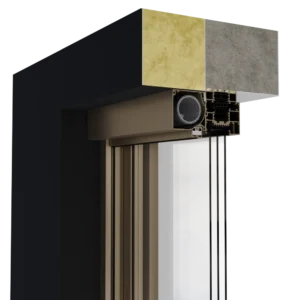

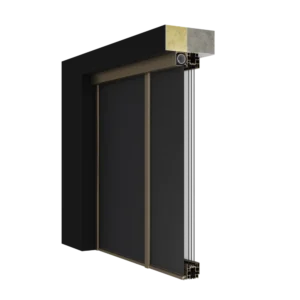

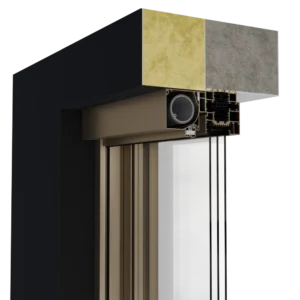

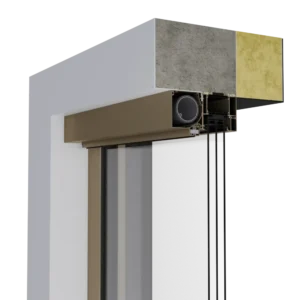

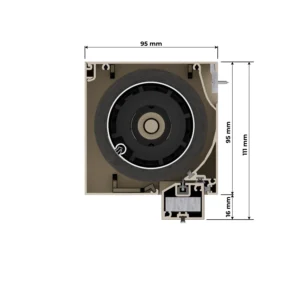

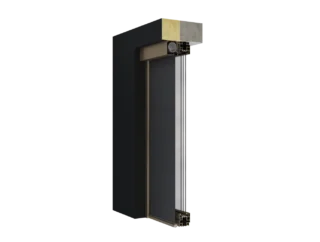

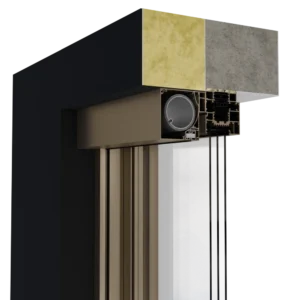

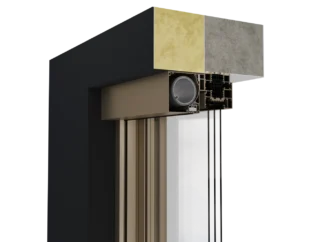

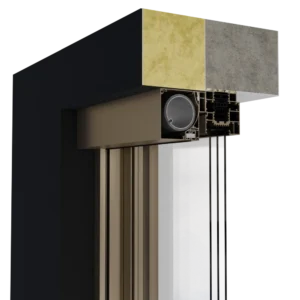

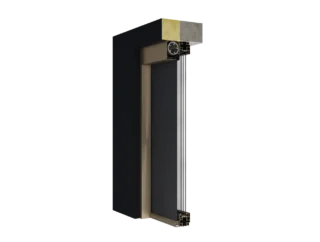

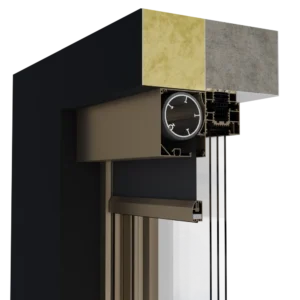

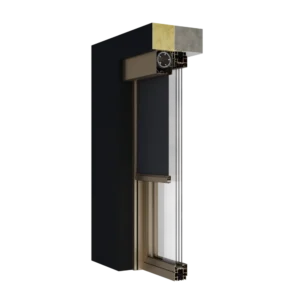

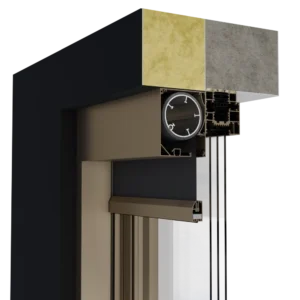

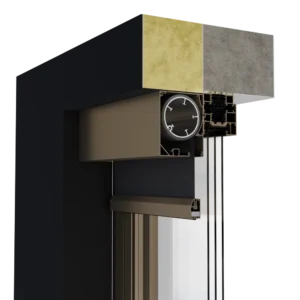

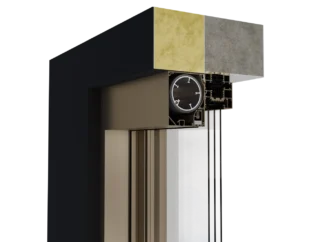

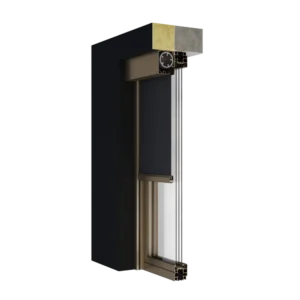

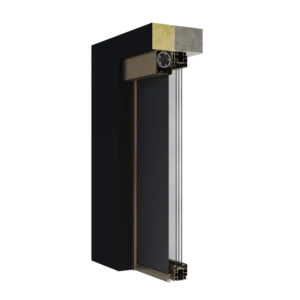

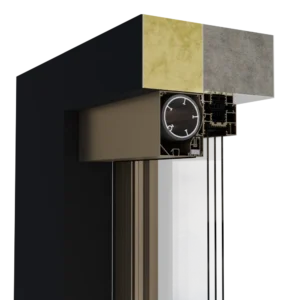

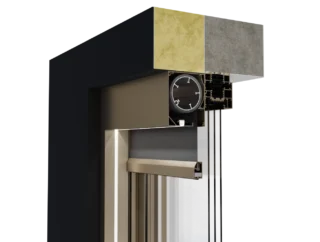

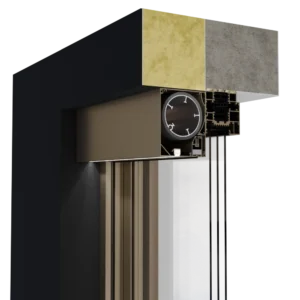

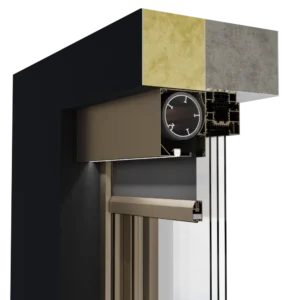

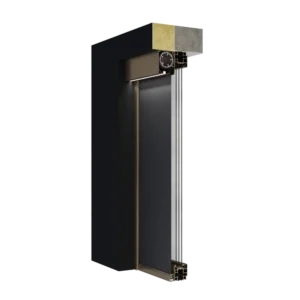

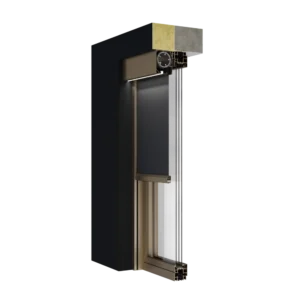

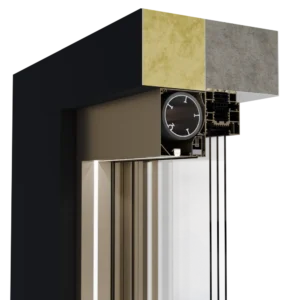

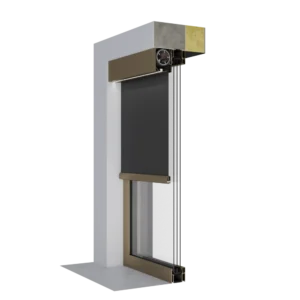

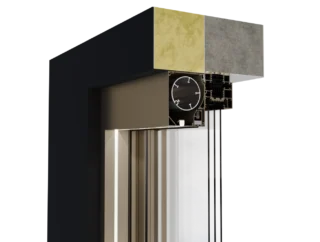

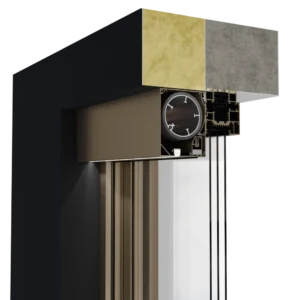

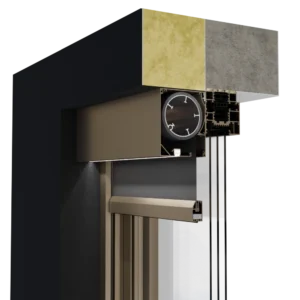

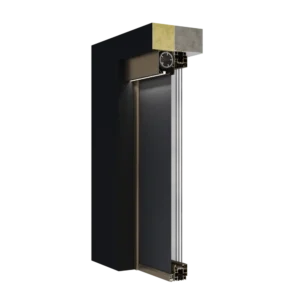

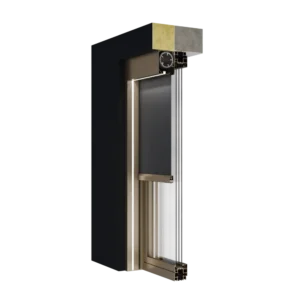

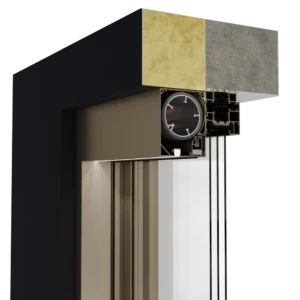

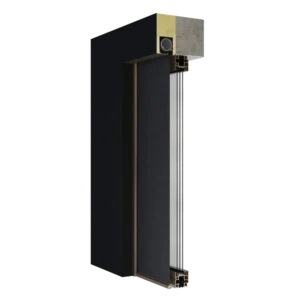

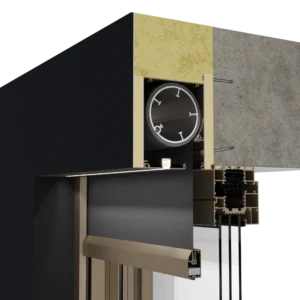

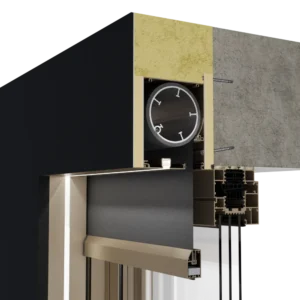

WS 95 A1 SLIM – MIT HALTERUNG

WS 95 A1 SLIM – MIT HALTERUNG

WS 95 A1 SLIM – MIT HALTERUNG

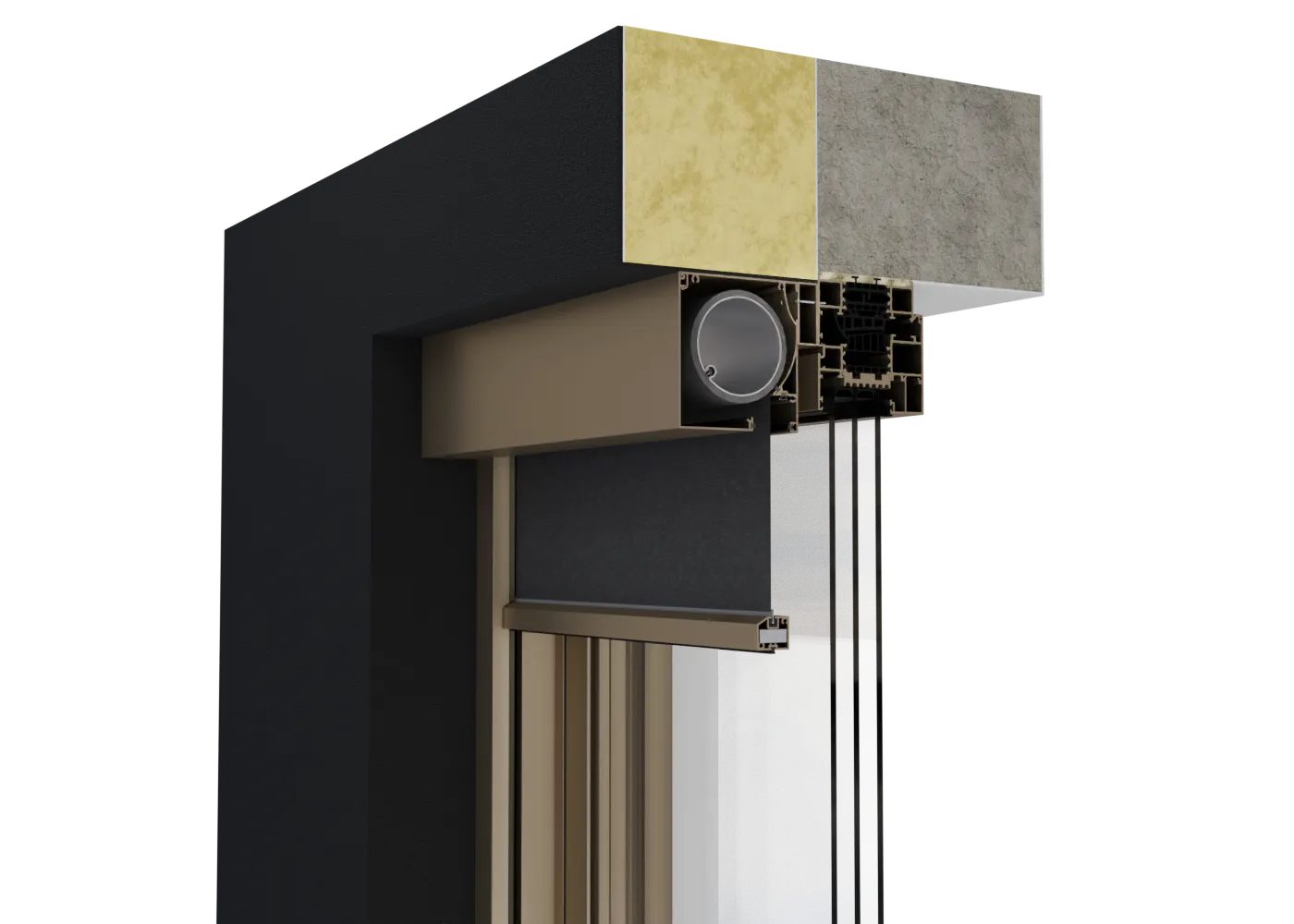

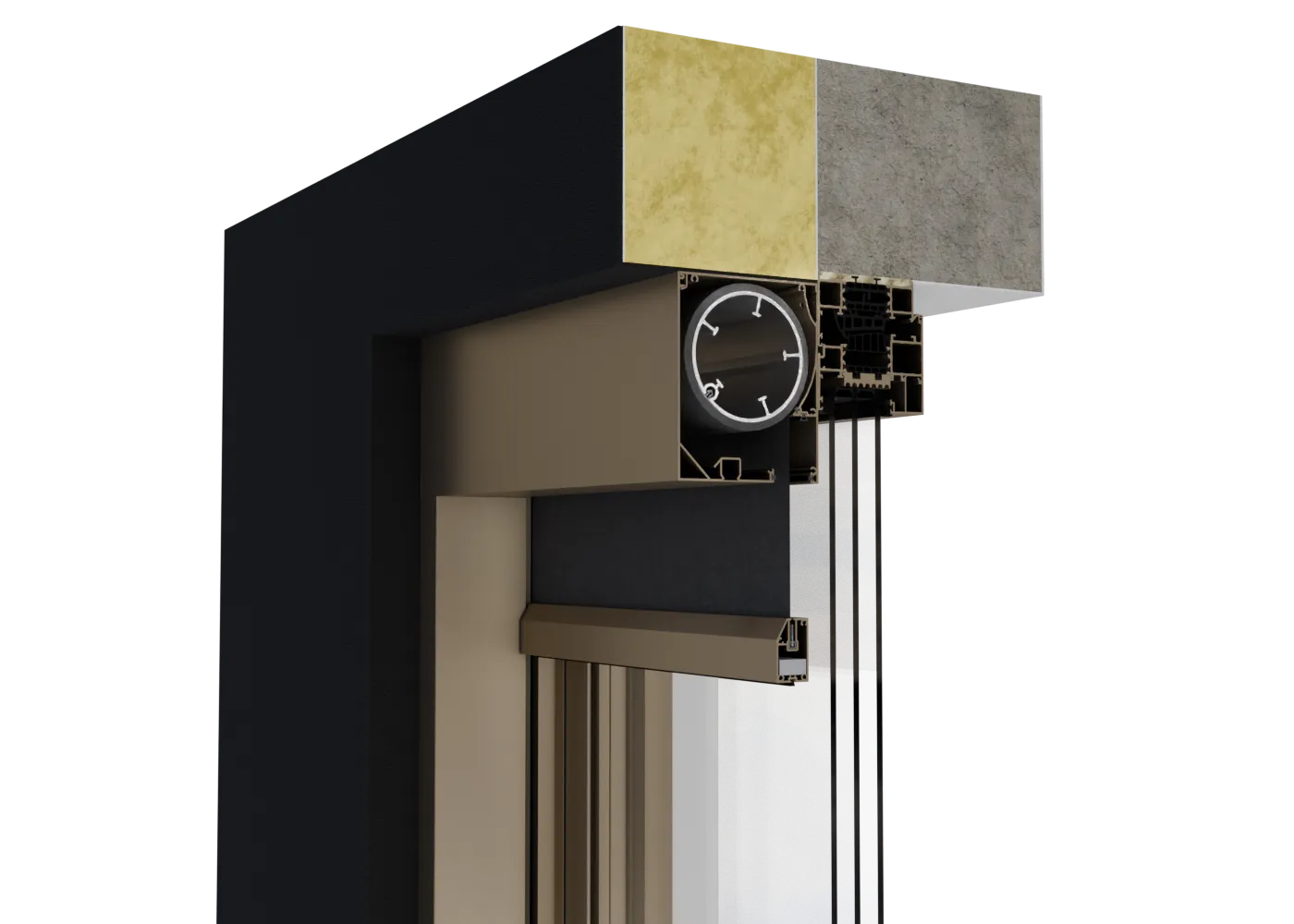

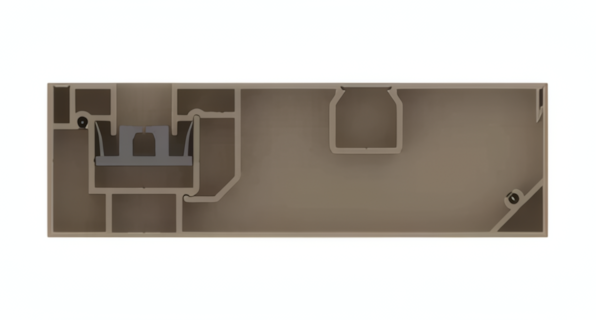

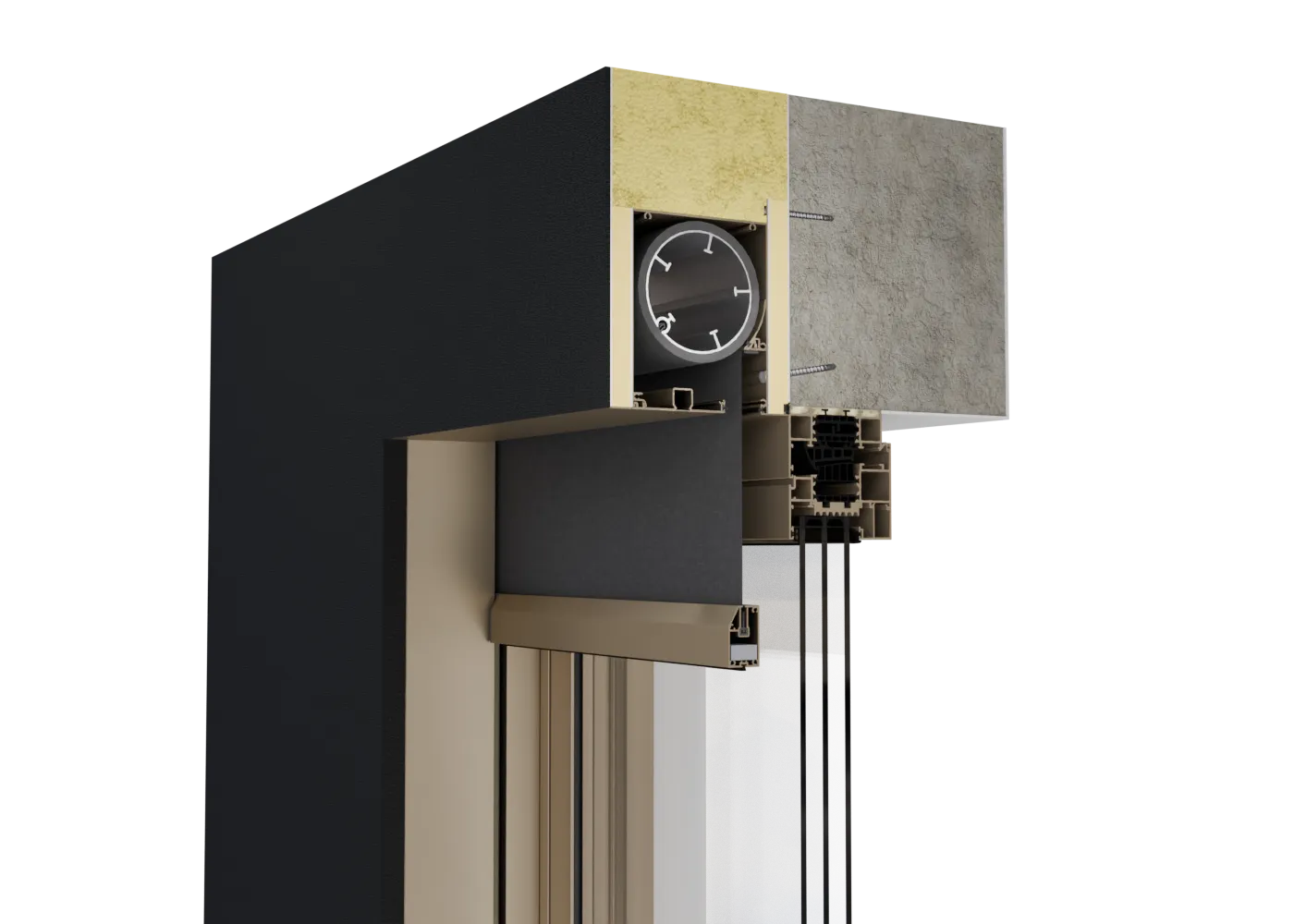

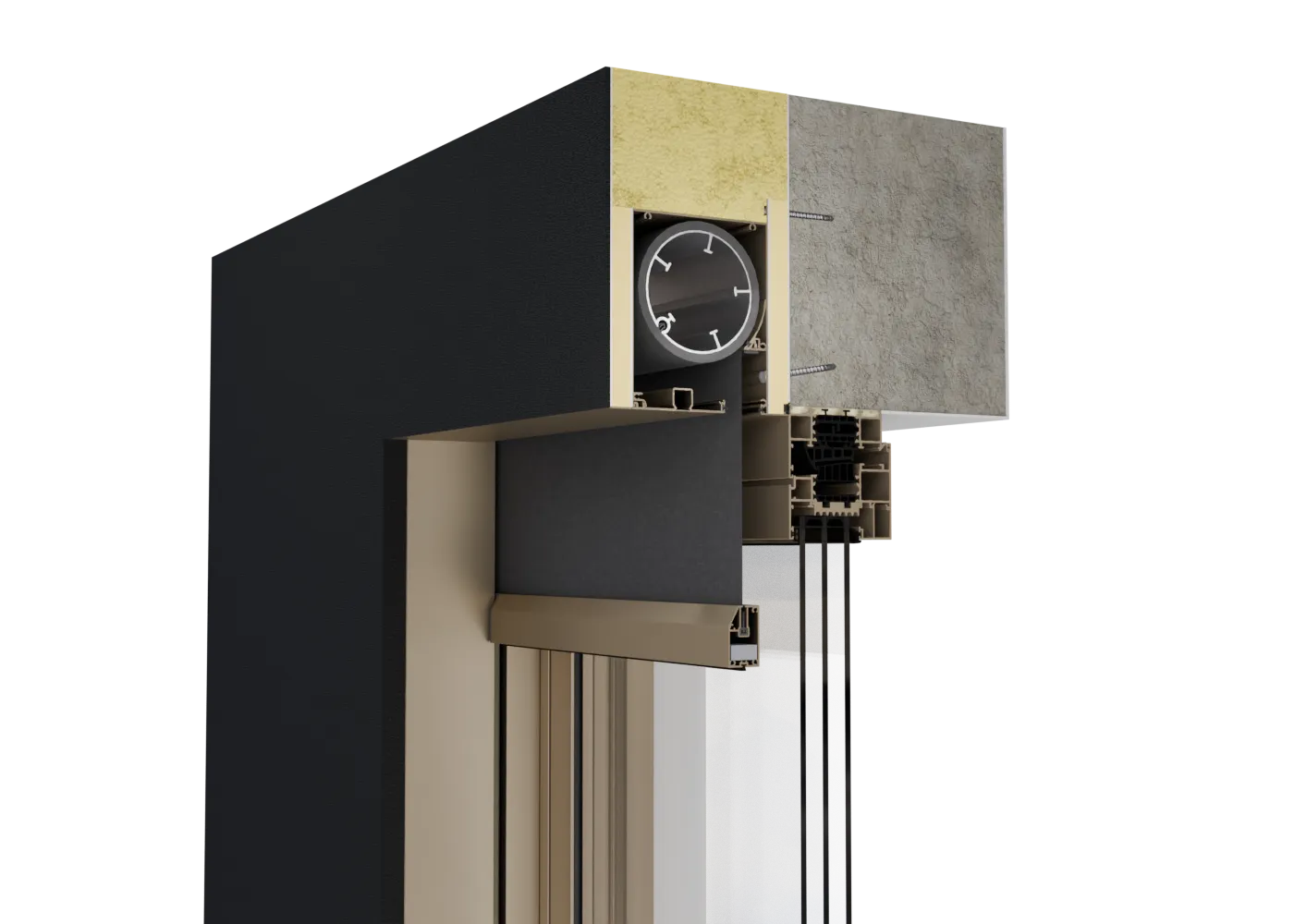

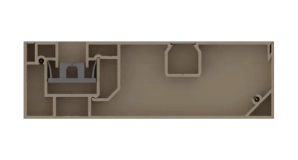

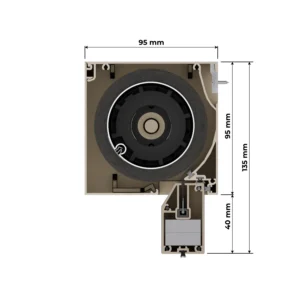

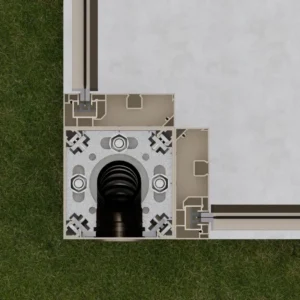

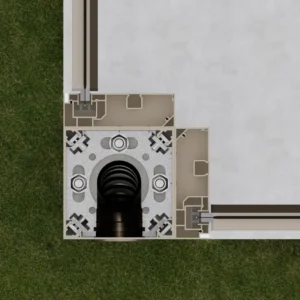

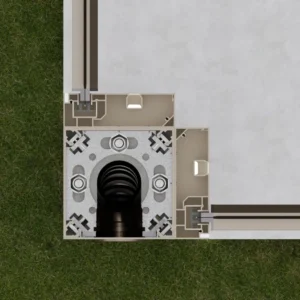

WS 95 A1 SLIM – MIT HALTERUNG ADAPTIVES SYSTEM WS 95 A1 SLIM, MIT HALTERUNG

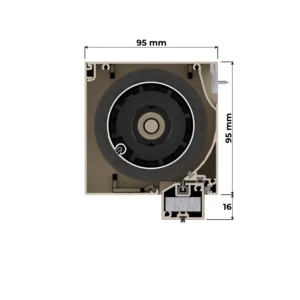

Kastengröße: 95 x 95 mm

Maximale Systemmaße: 3600 x 3300 mm \[11,88 m²]

Rohrdurchmesser: ∅ 63 mm

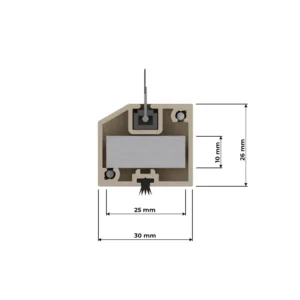

Untere Leisten: LD-1 (schiebt sich nicht vollständig in den Kasten), LD-2 (schiebt sich nicht vollständig in den Kasten)

HINWEIS: Bei Rollläden mit einer Breite bis zu 1200 mm wird die belastende untere Leiste LD-2 verwendet, die sich nicht vollständig in den Kasten schiebt

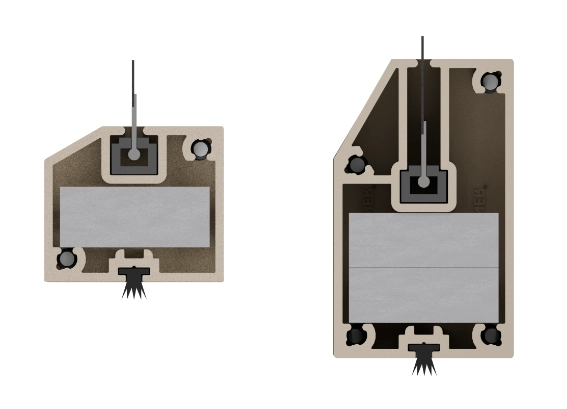

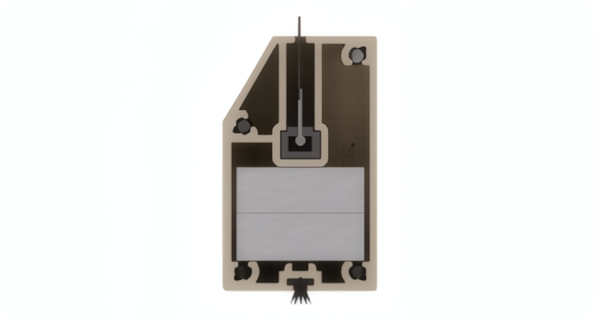

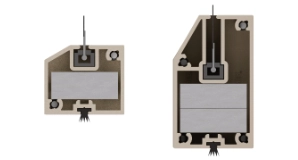

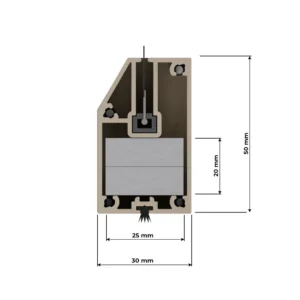

BEISPIELHAFTE SYSTEMQUERSCHNITTE

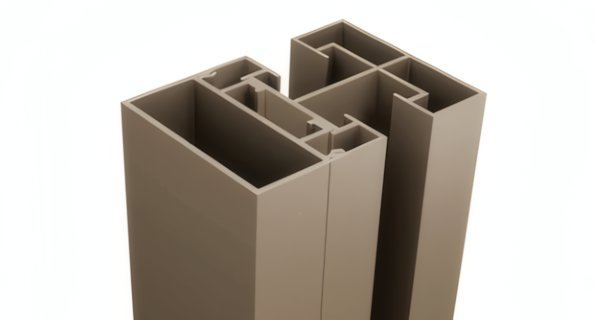

FÜHRUNGEN

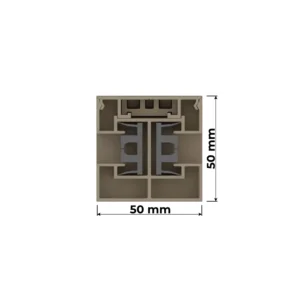

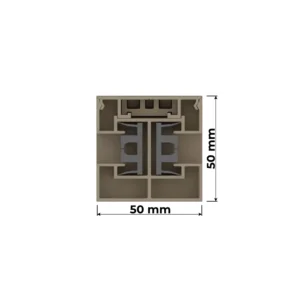

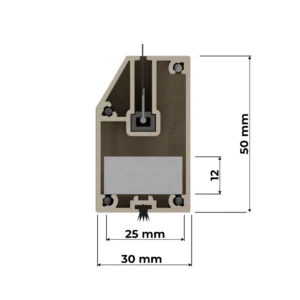

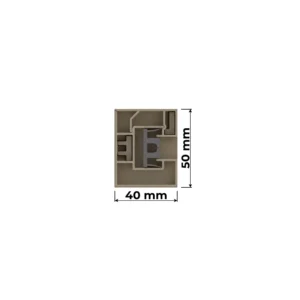

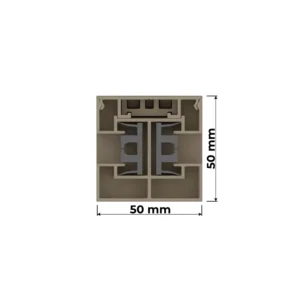

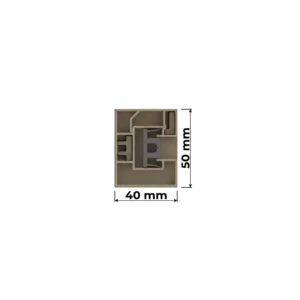

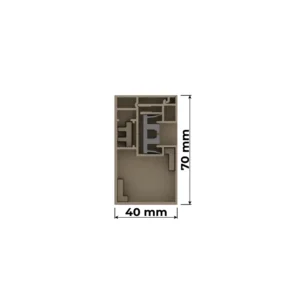

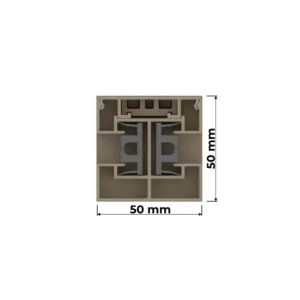

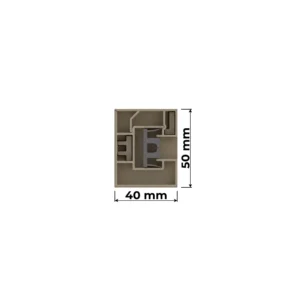

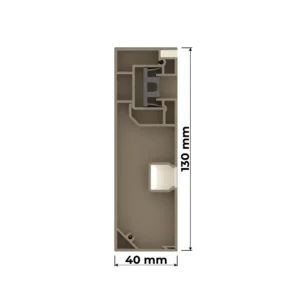

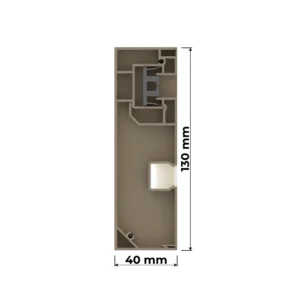

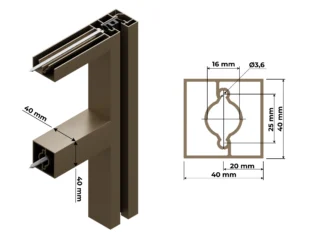

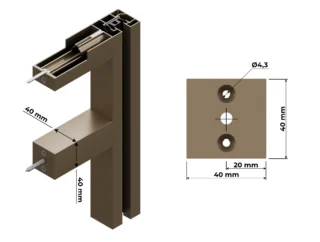

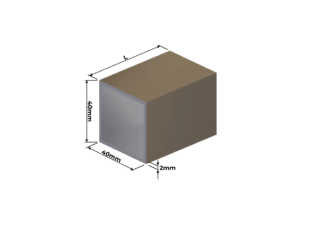

EINZELFÜHRUNG ZIP: AS-1 SLIM

UNTERLEISTEN

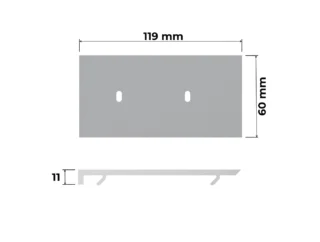

UNTERLEISTE LD-1

UNTERLEISTE LD-2

\*Die untere Leiste LD-2 wird bei Rollläden mit einer Breite bis zu 1200 mm verwendet und schiebt sich nicht vollständig in den Kasten.

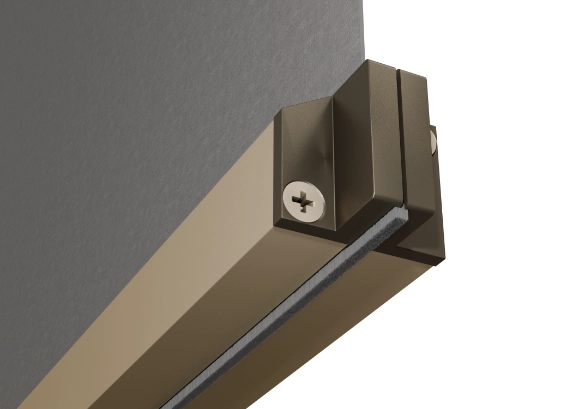

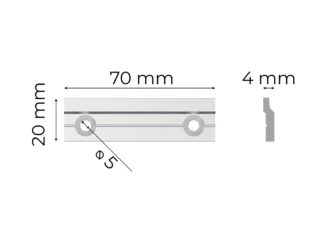

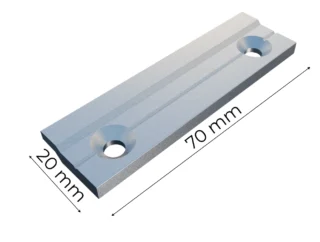

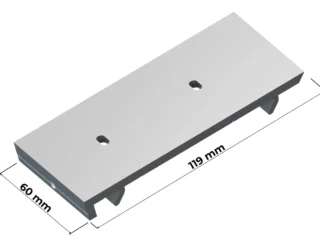

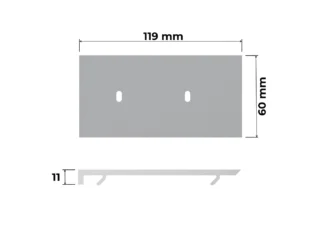

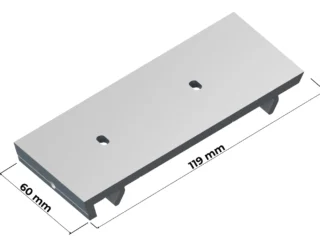

MONTAGEHALTERUNGEN

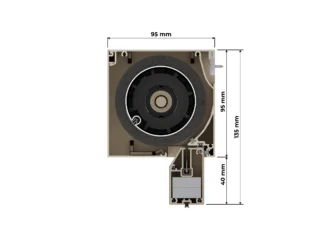

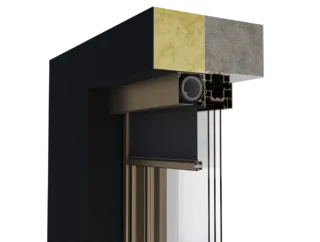

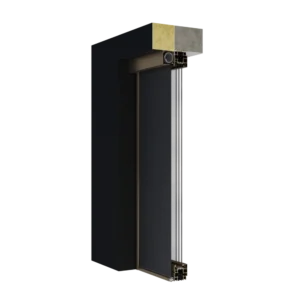

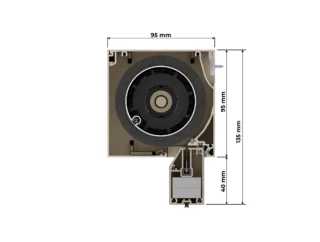

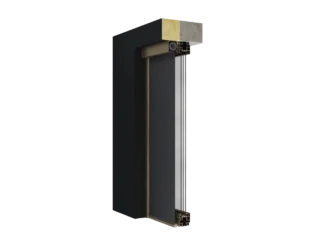

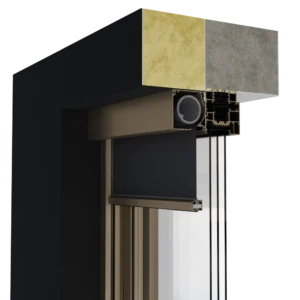

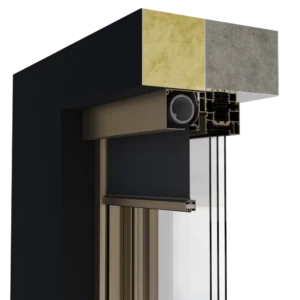

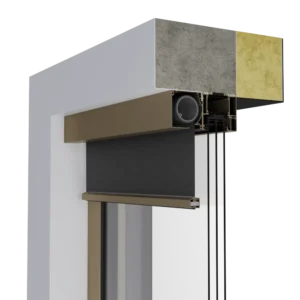

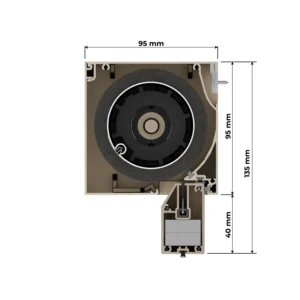

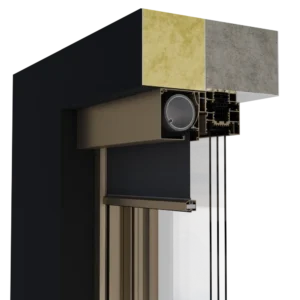

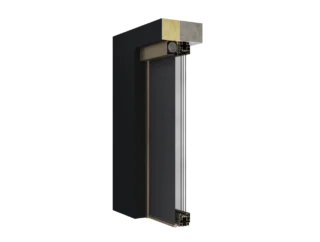

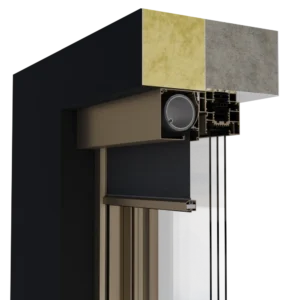

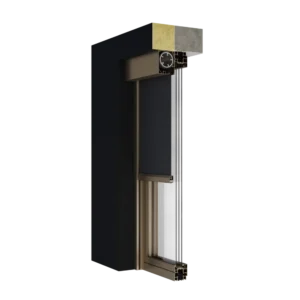

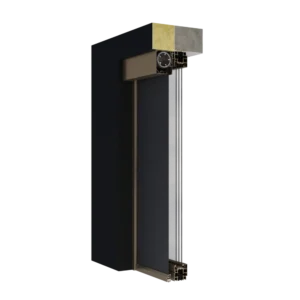

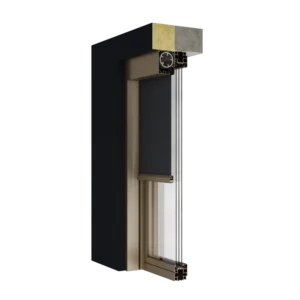

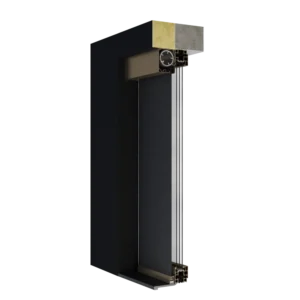

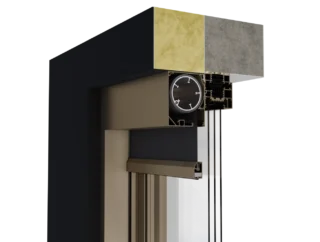

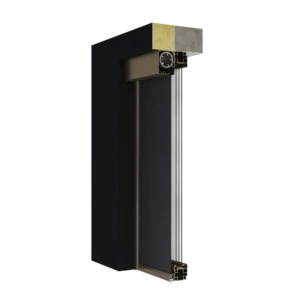

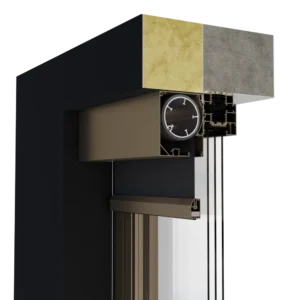

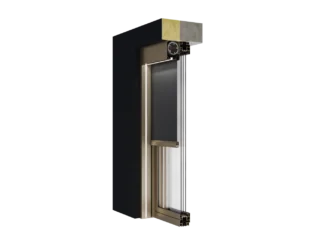

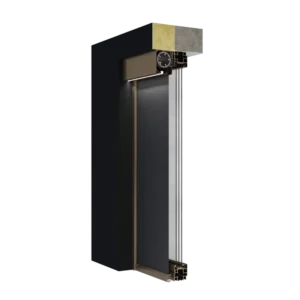

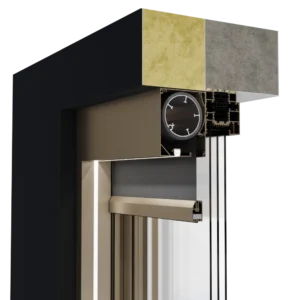

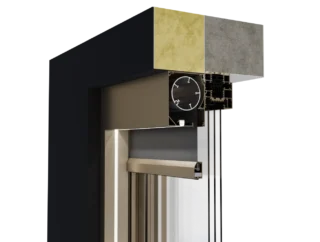

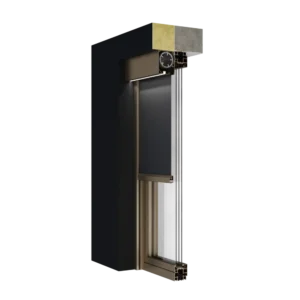

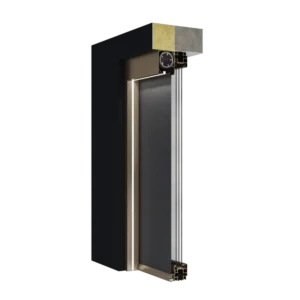

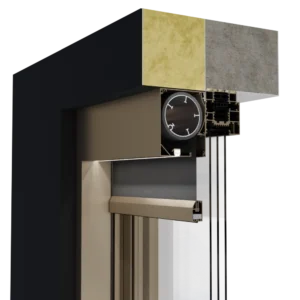

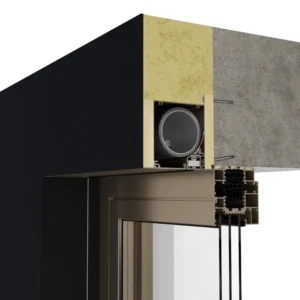

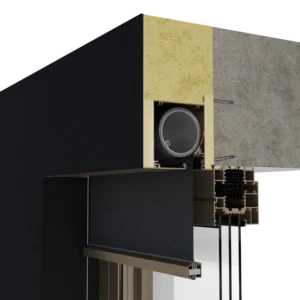

WS 95 A2 – MIT HALTERUNG

WS 95 A2 – MIT HALTERUNG

WS 95 A2 – MIT HALTERUNG

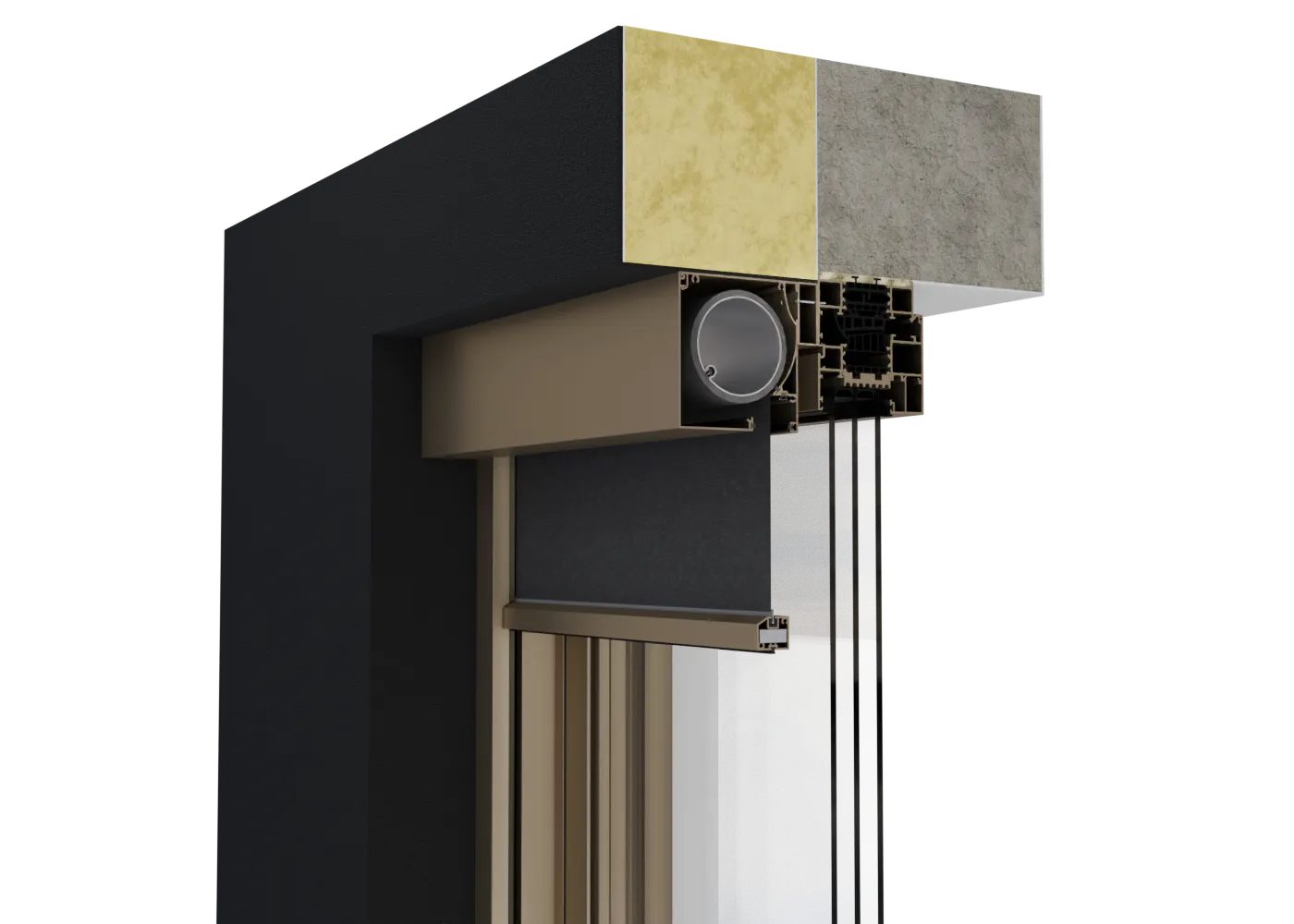

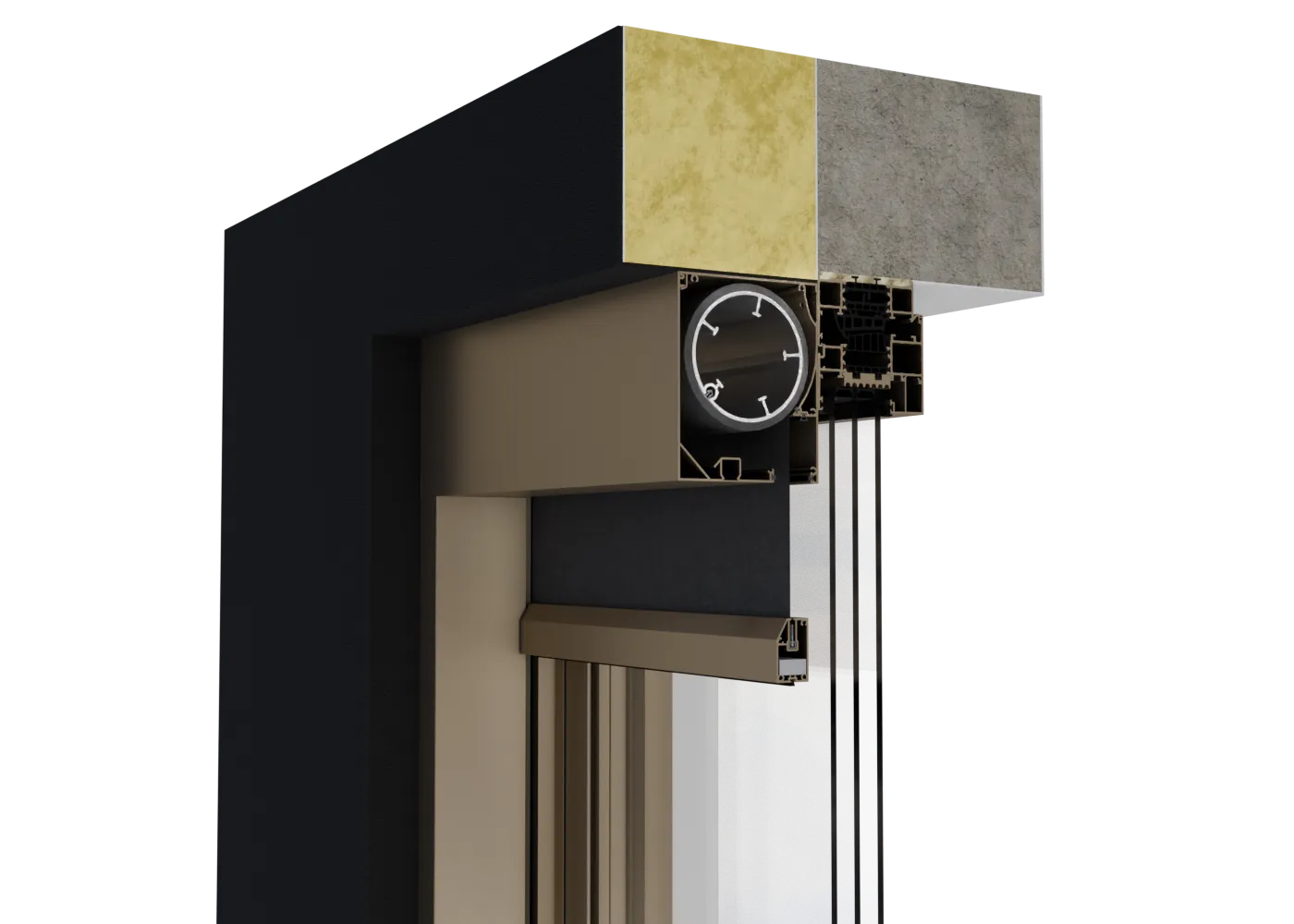

WS 95 A2 – MIT HALTERUNG ADAPTIVES SYSTEM WS 95 A2, MIT HALTERUNG

Kastengröße: 95 x 95 mm

Maximale Systemmaße: 3600 x 3300 mm \[11,88 m²]

Rohrdurchmesser: ∅ 63 mm

Untere Leisten: LD-1 (schiebt sich nicht vollständig in den Kasten), LD-2 (schiebt sich nicht vollständig in den Kasten)

HINWEIS: Bei Rollläden mit einer Breite bis zu 1200 mm wird die belastende untere Leiste LD-2 verwendet, die sich nicht vollständig in den Kasten schiebt

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

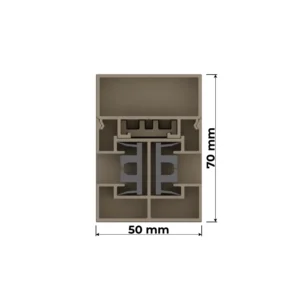

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-1

* UNTERLEISTE LD-2

* Die untere Leiste LD-2 wird bei Rollläden mit einer Breite bis zu 1200 mm verwendet und schiebt sich nicht vollständig in den Kasten.

MONTAGEHALTERUNGEN

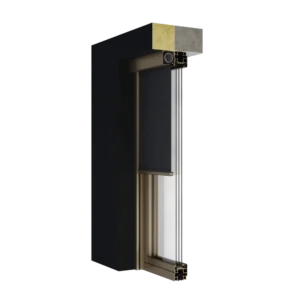

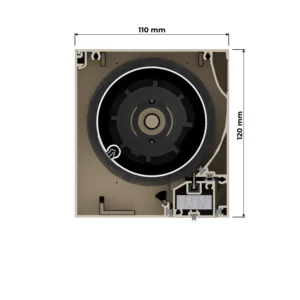

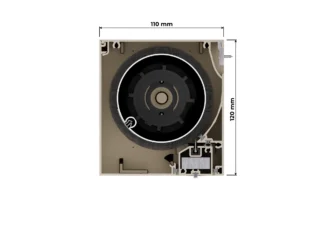

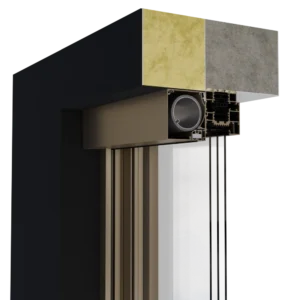

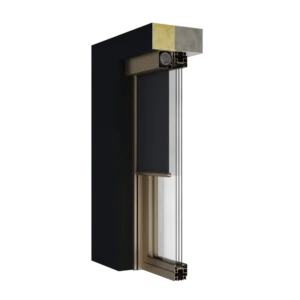

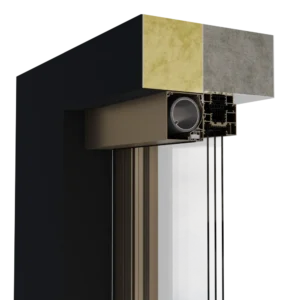

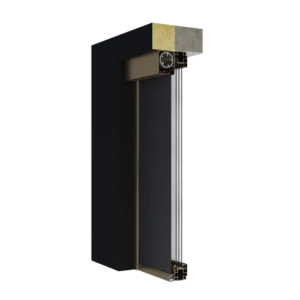

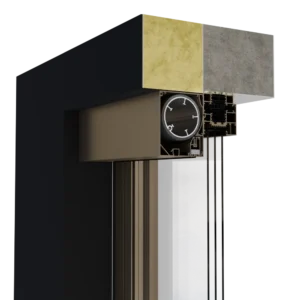

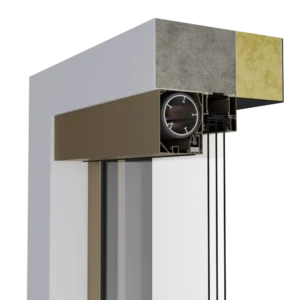

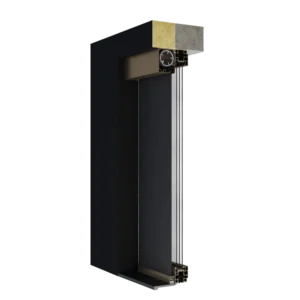

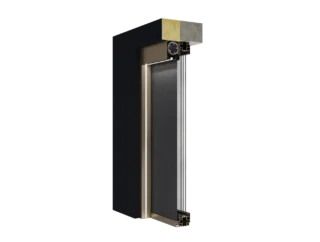

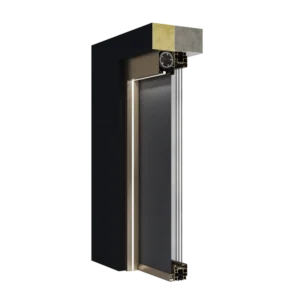

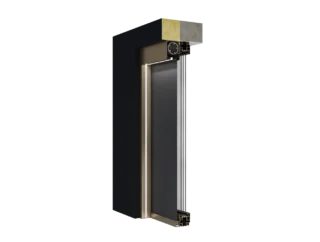

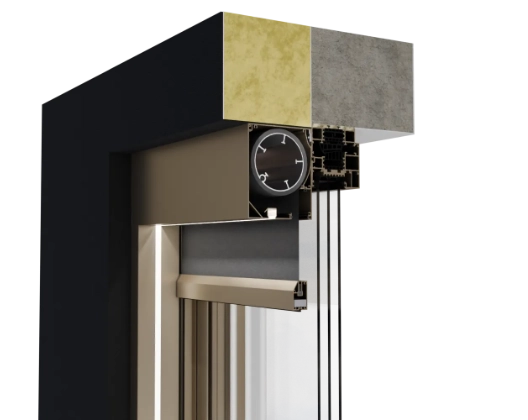

WS 110 A3

WS 110 A3

WS 110 A3

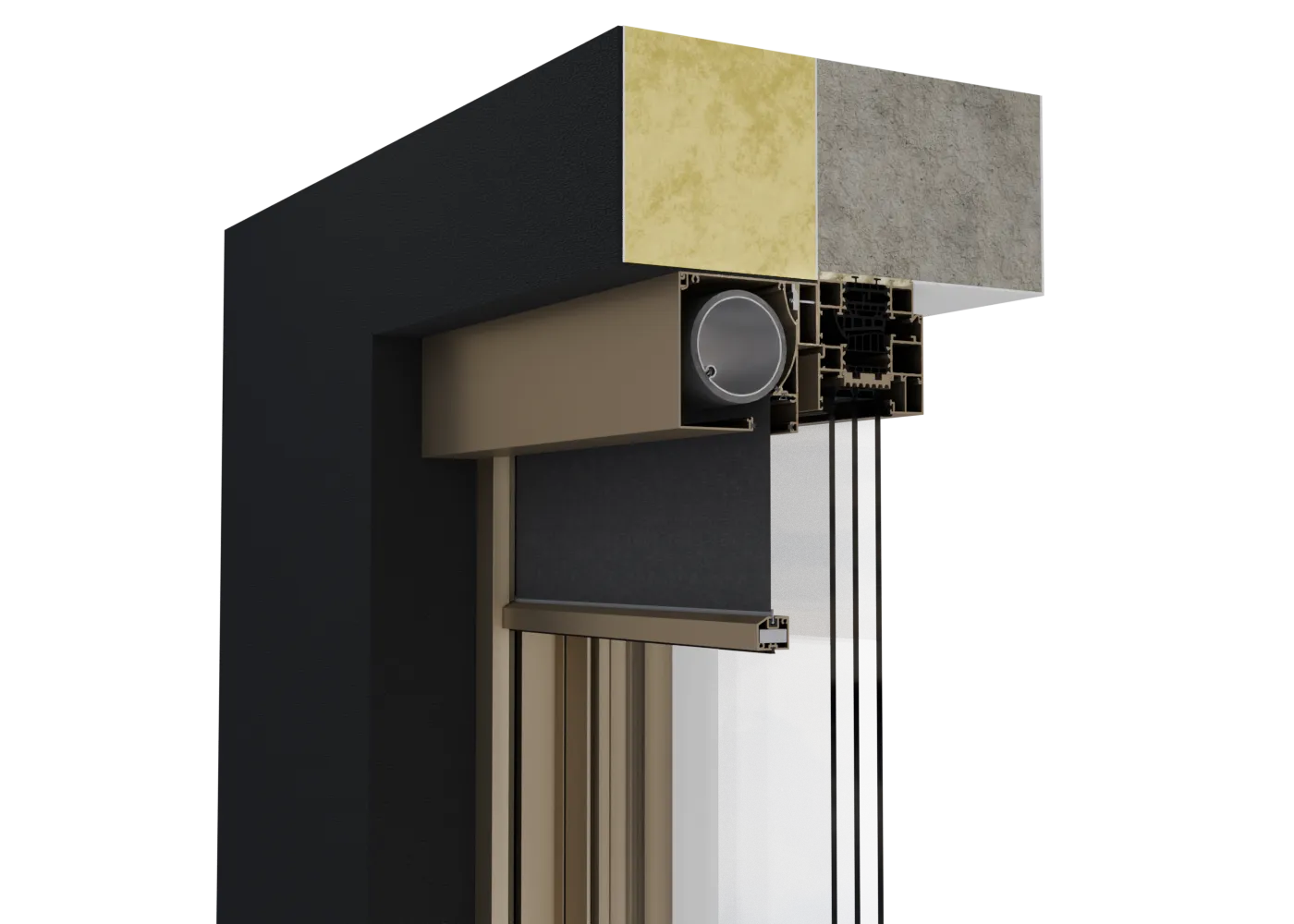

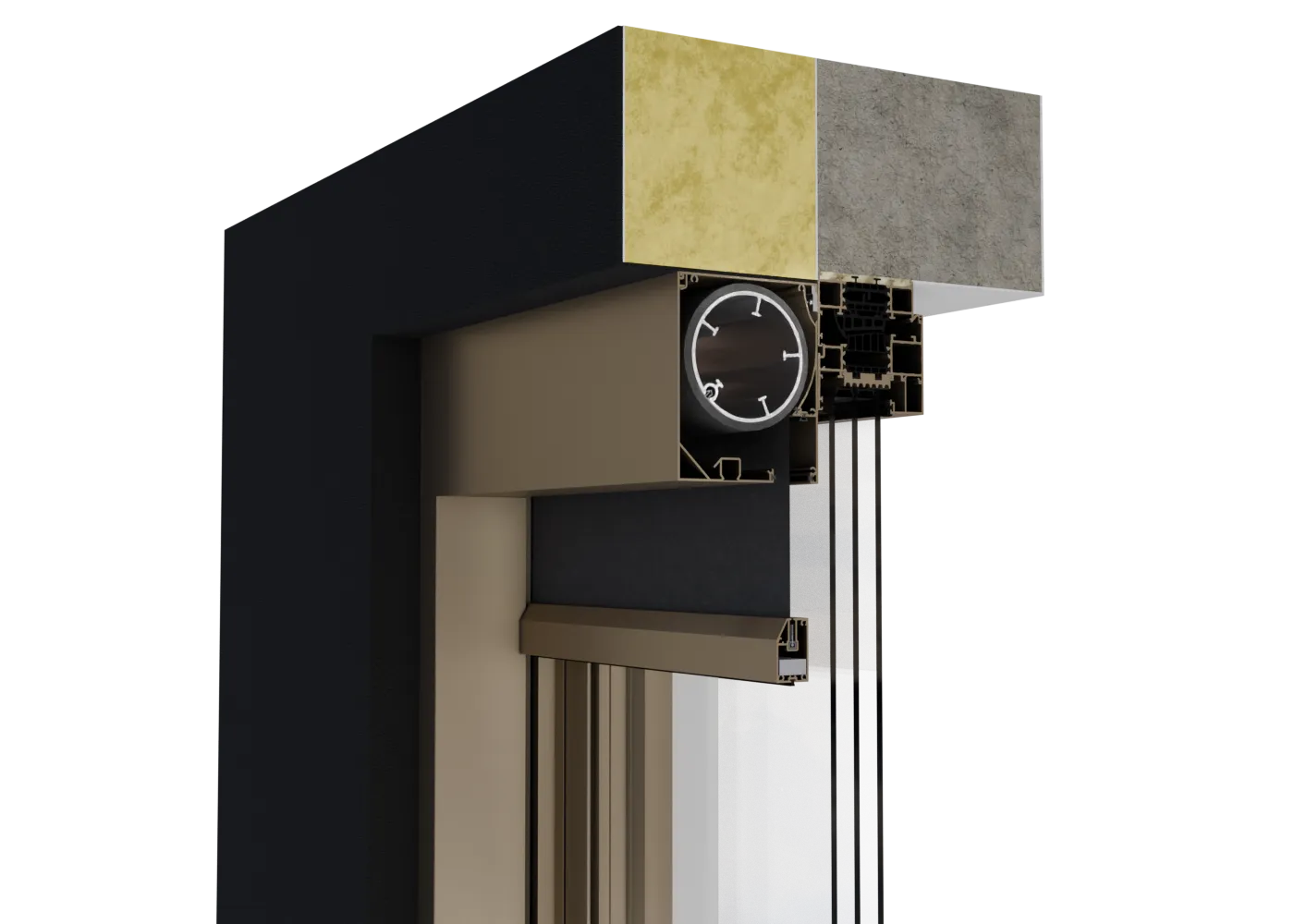

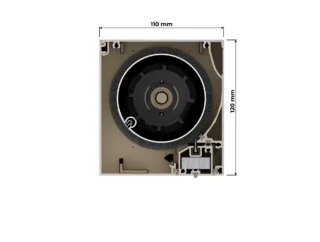

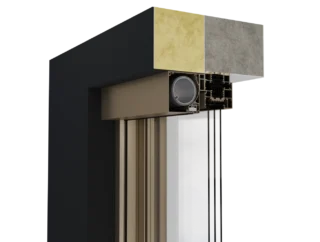

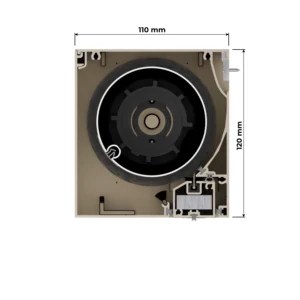

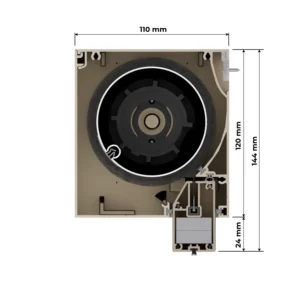

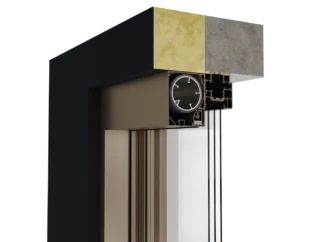

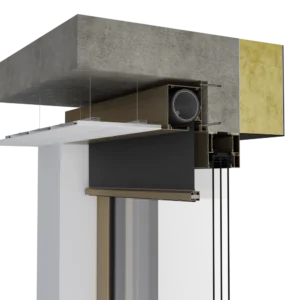

WS 110 A3 ADAPTIVES SYSTEM WS 110 A3

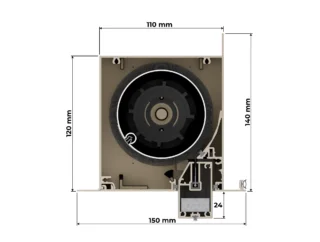

Kastengröße: 110 x 120 mm

Maximale Systemmaße: 5000 x 3000 mm \[15 m²] oder 4000 x 4000 mm \[16 m²]

Rohrdurchmesser: ∅ 63 mm, ∅ 78 mm

Untere Leisten: LD-1 (schiebt sich vollständig in den Kasten), LD-2 (schiebt sich nicht vollständig in den Kasten)

HINWEIS: Bei Rollläden mit einer Breite bis zu 1200 mm wird die belastende untere Leiste LD-2 verwendet, die sich nicht vollständig in den Kasten schiebt

BEISPIELHAFTE SYSTEMQUERSCHNITTE

VERFÜGBARE FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-1

* UNTERLEISTE LD-2

* Die untere Leiste LD-2 wird bei Rollläden mit einer Breite bis zu 1200 mm verwendet und schiebt sich nicht vollständig in den Kasten.

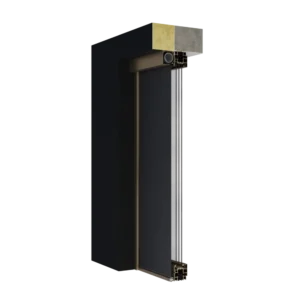

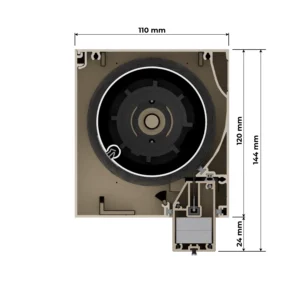

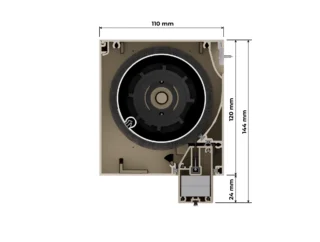

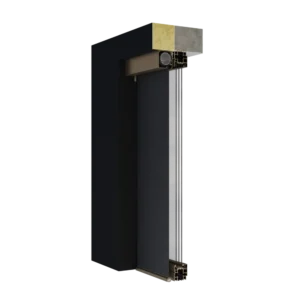

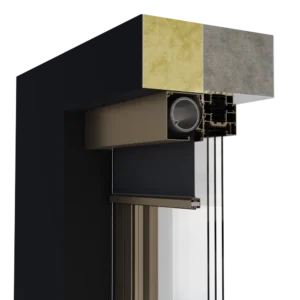

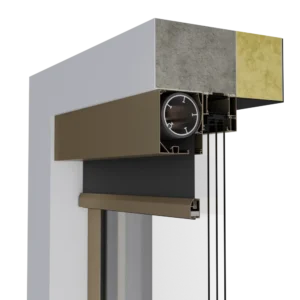

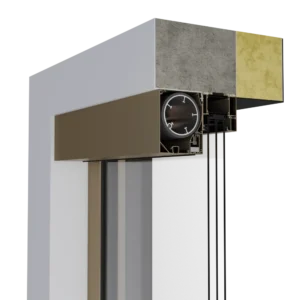

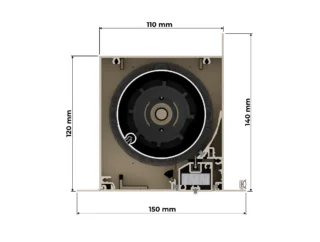

WS 110 A4 – MIT HALTERUNG

WS 110 A4 – MIT HALTERUNG

WS 110 A4 – MIT HALTERUNG

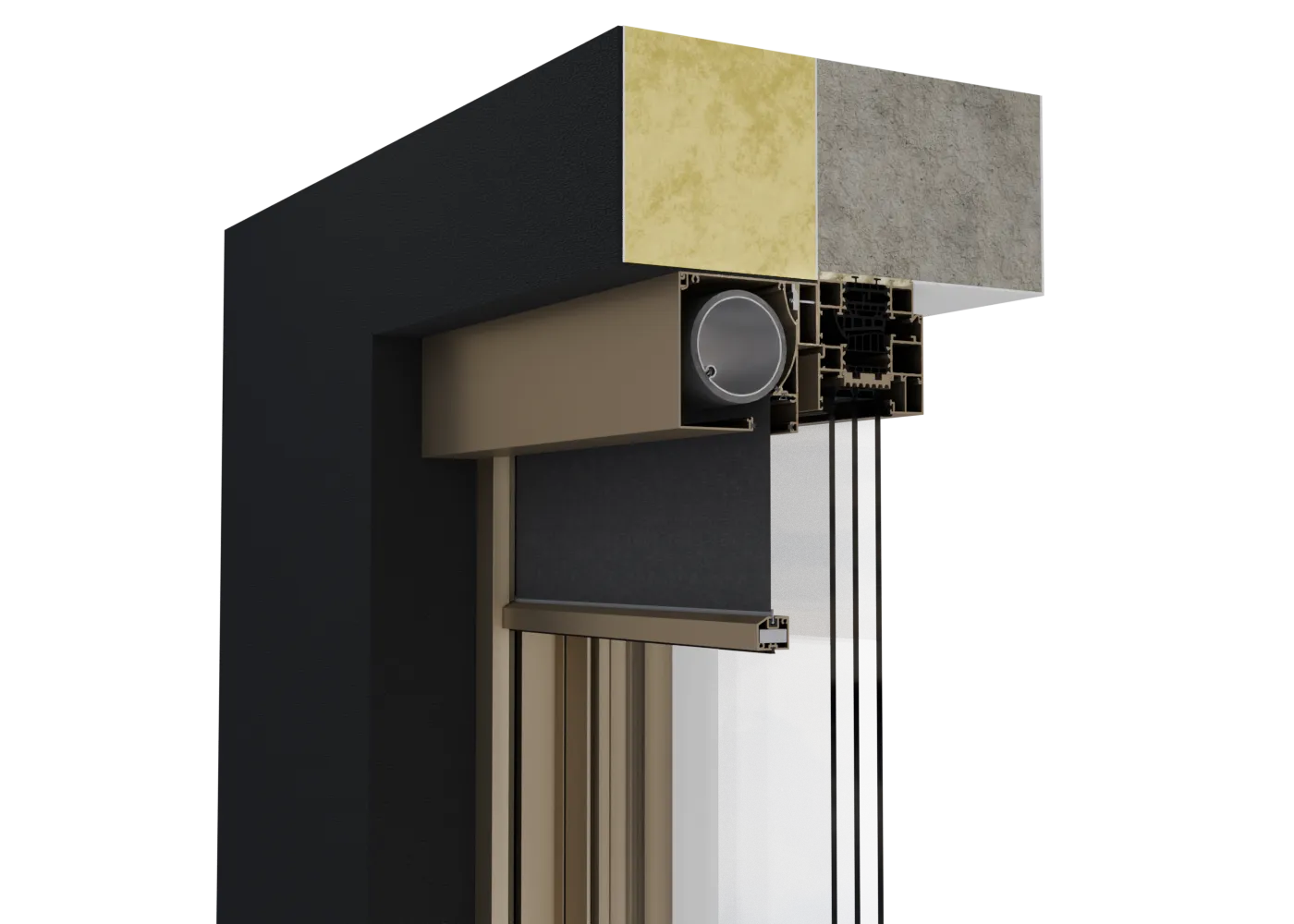

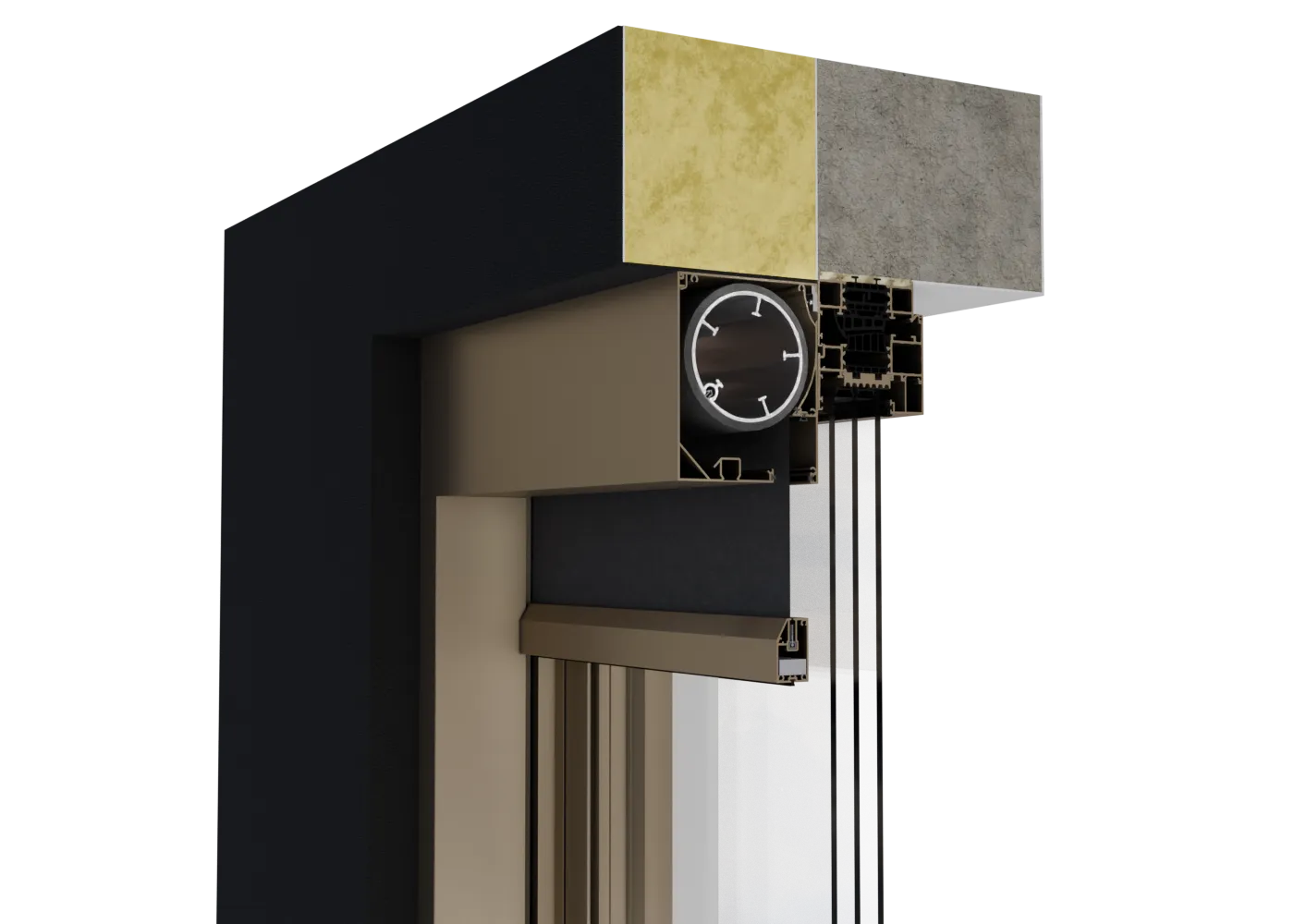

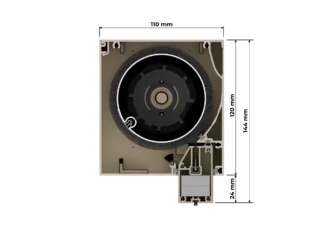

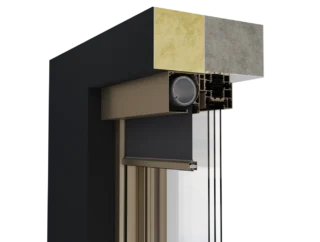

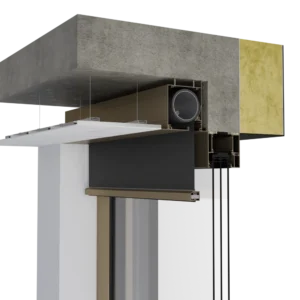

WS 110 A4 – MIT HALTERUNG ADAPTIVES SYSTEM WS 110 A4, MIT HALTERUNG

Kastengröße: 110 x 120 mm

Maximale Systemmaße: 5000 x 3000 mm \[15 m²] oder 4000 x 4000 mm \[16 m²]

Rohrdurchmesser: ∅ 63 mm, ∅ 78 mm

Untere Leisten: LD-1 (schiebt sich vollständig in den Kasten), LD-2 (schiebt sich nicht vollständig in den Kasten)

HINWEIS: Bei Rollläden mit einer Breite bis zu 1200 mm wird die belastende untere Leiste LD-2 verwendet, die sich nicht vollständig in den Kasten schiebt

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-1

* UNTERLEISTE LD-2

* Die untere Leiste LD-2 wird bei Rollläden mit einer Breite bis zu 1200 mm verwendet und schiebt sich nicht vollständig in den Kasten.

MONTAGEHALTERUNGEN

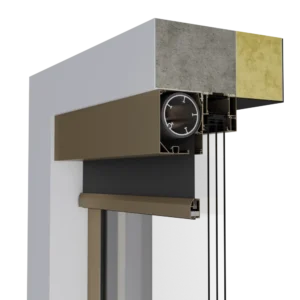

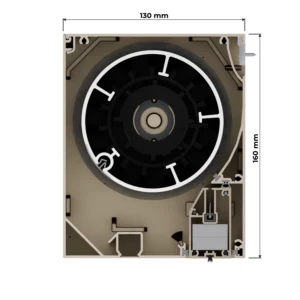

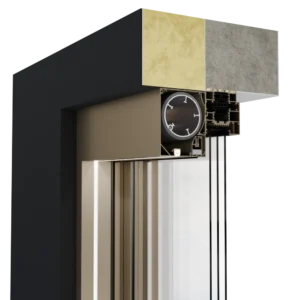

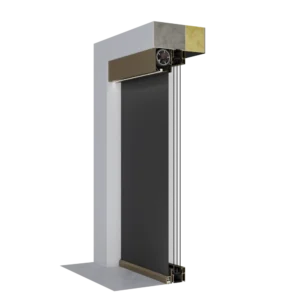

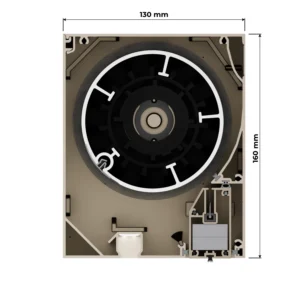

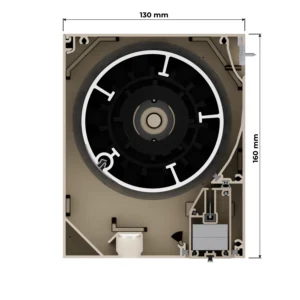

WS 130 A5

WS 130 A5

WS 130 A5

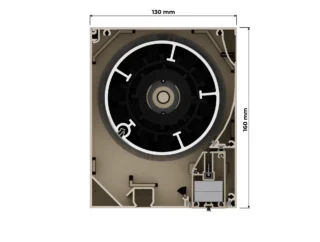

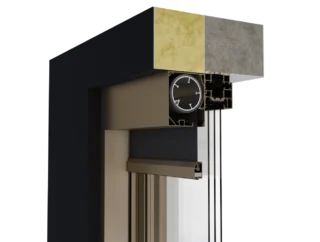

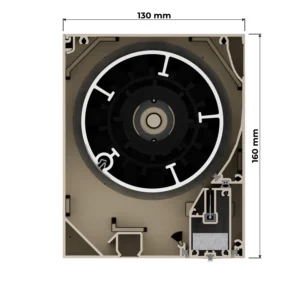

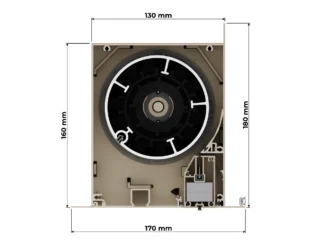

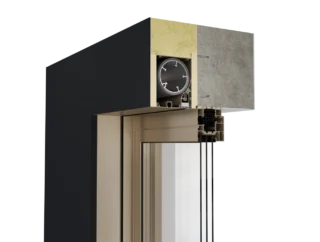

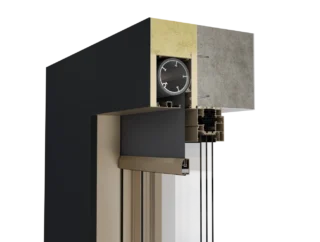

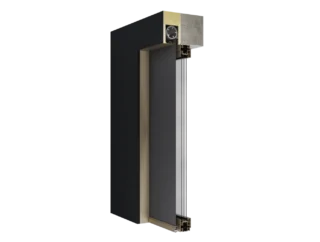

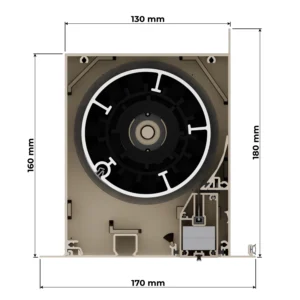

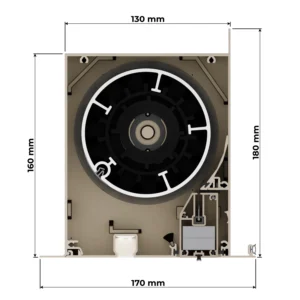

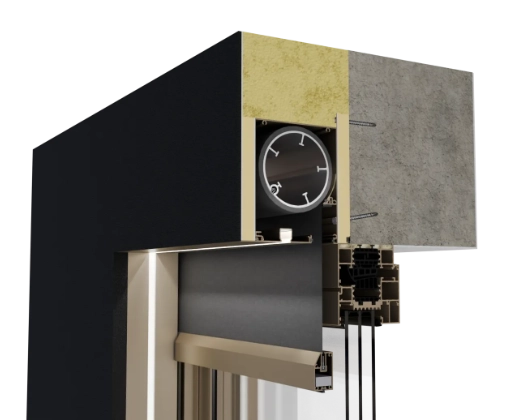

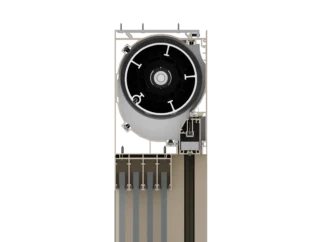

WS 130 A5 ADAPTIVES SYSTEM WS 130 A5

Kastengröße: 130 x 160 mm

Maximale Systemmaße: 7000 x 3400 mm \[23,80 m²] oder 5400 x 6000 mm \[32,40 m²]

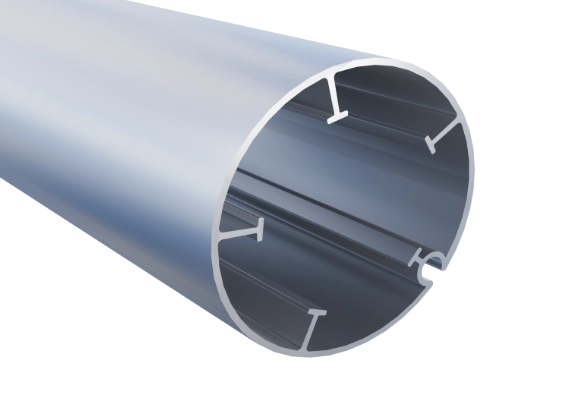

Rohrdurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Untere Leiste: LD-2 (schiebt sich vollständig in den Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

EINZELFÜHRUNG ZIP: P3

EINZELFÜHRUNG ZIP: Z2

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-2

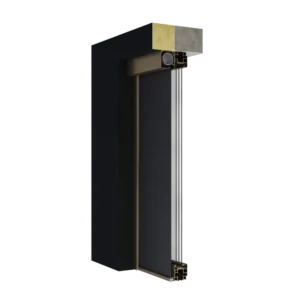

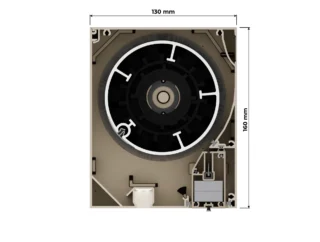

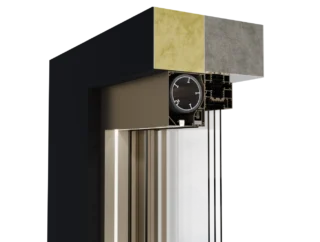

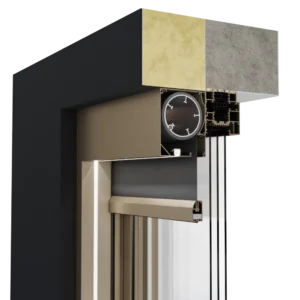

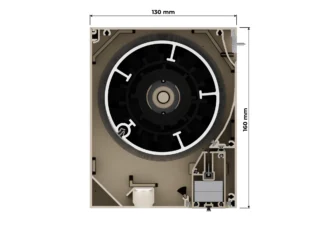

WS 130 A6 – MIT HALTERUNG

WS 130 A6 – MIT HALTERUNG

WS 130 A6 – MIT HALTERUNG

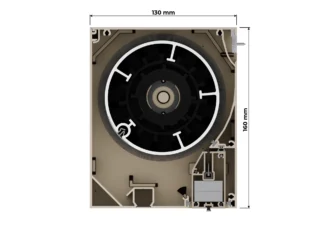

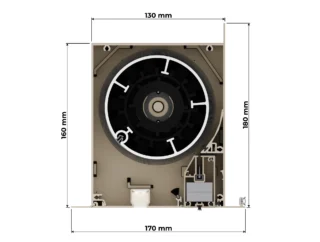

WS 130 A6 – MIT HALTERUNG ADAPTIVES SYSTEM WS 130 A6, MIT HALTERUNG

Kastengröße: 130 x 160 mm

Maximale Systemmaße: 7000 x 3400 mm \[23,80 m²] oder 5400 x 6000 mm \[32,40 m²]

Rohrdurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Untere Leiste: LD-2 (schiebt sich vollständig in den Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

EINZELFÜHRUNG ZIP: P3

EINZELFÜHRUNG ZIP: Z2

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-2

MONTAGEHALTERUNGEN

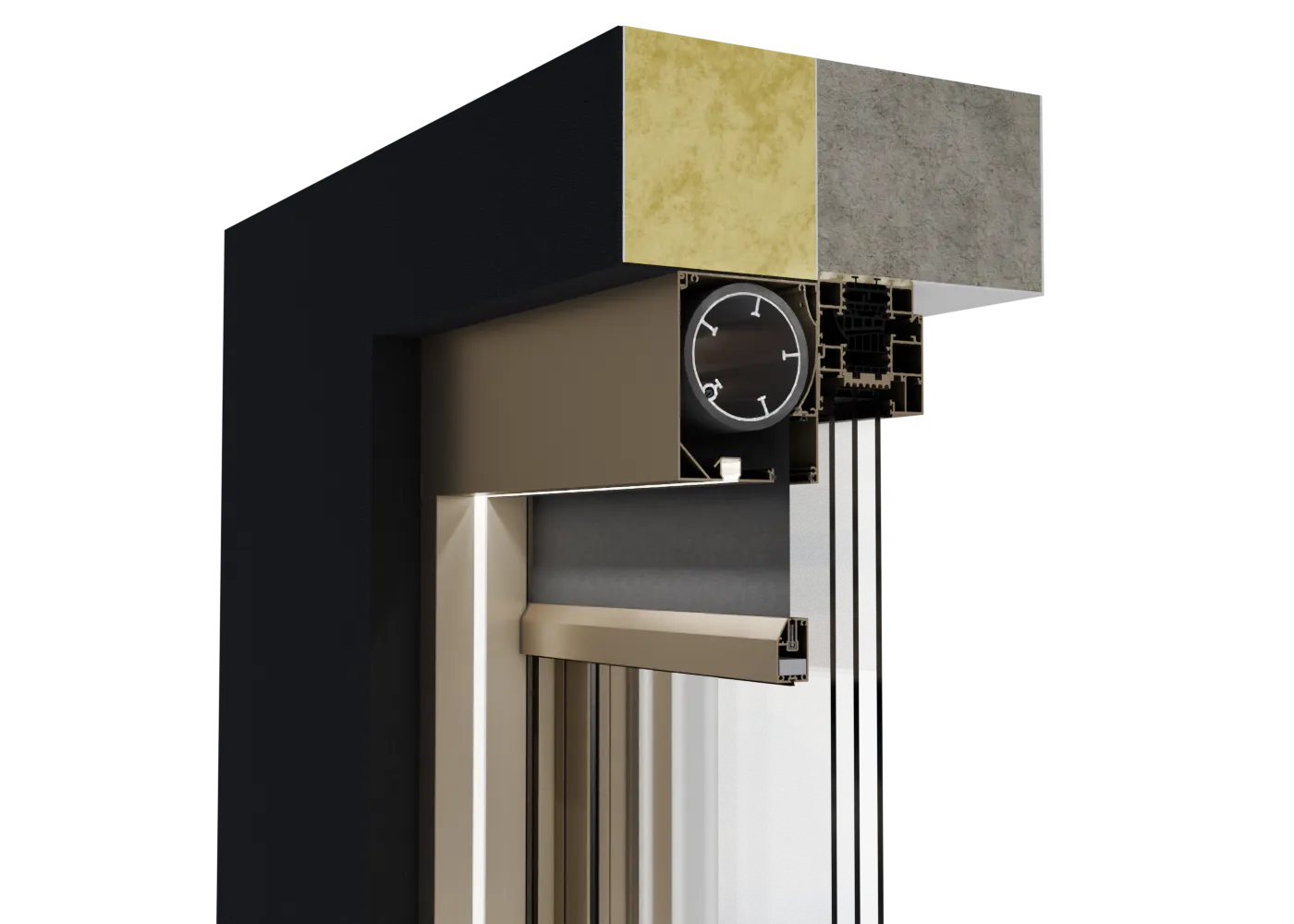

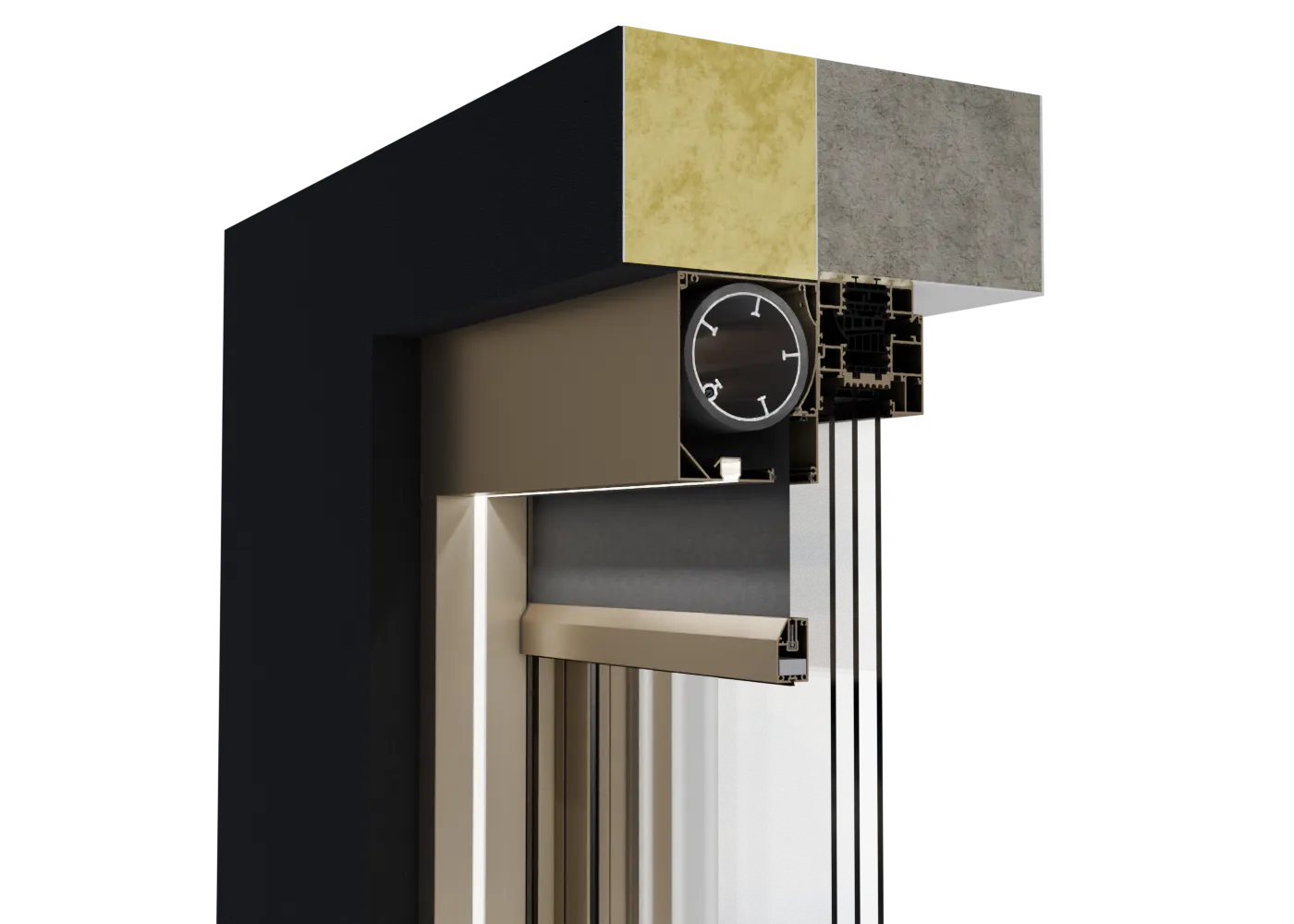

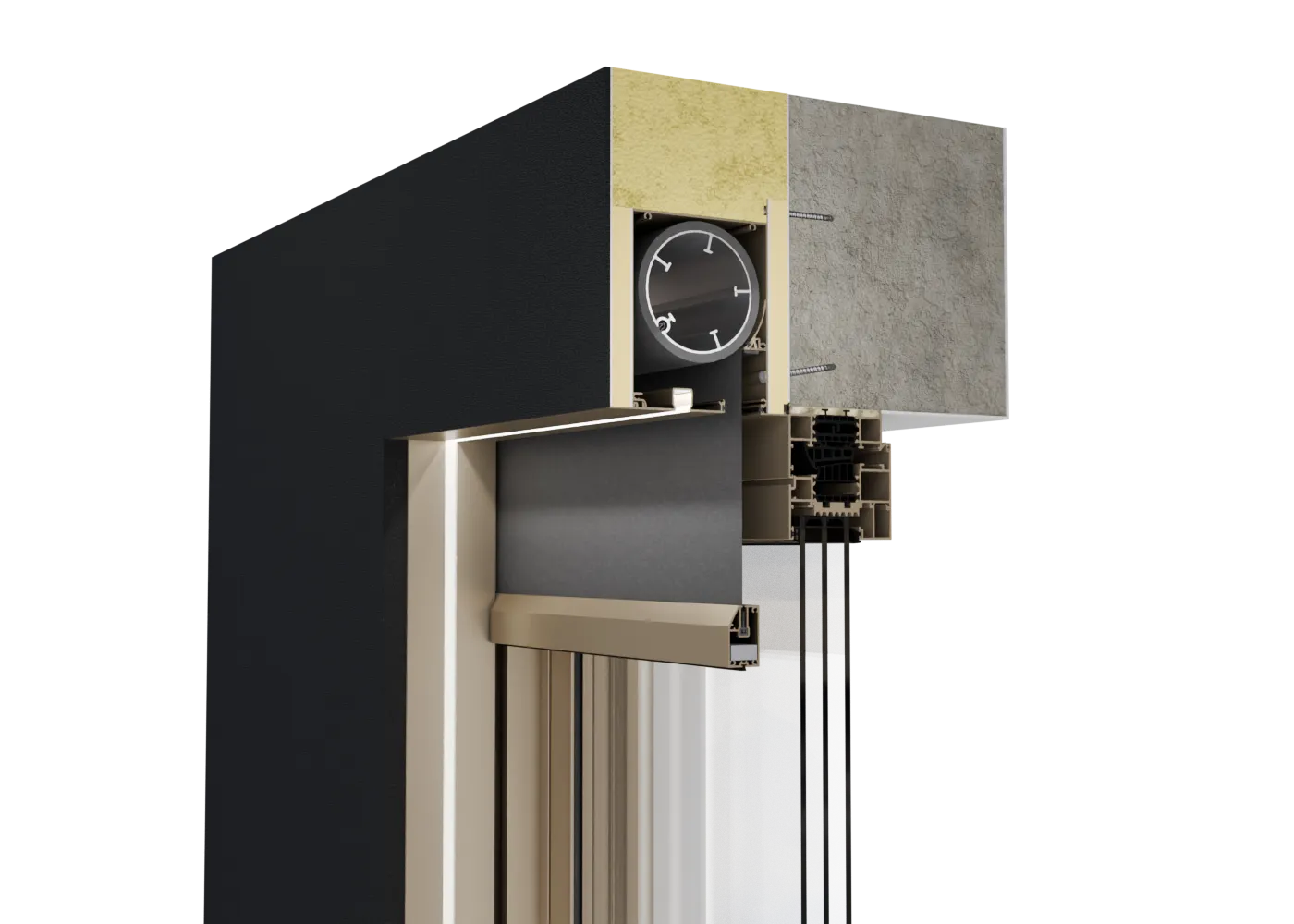

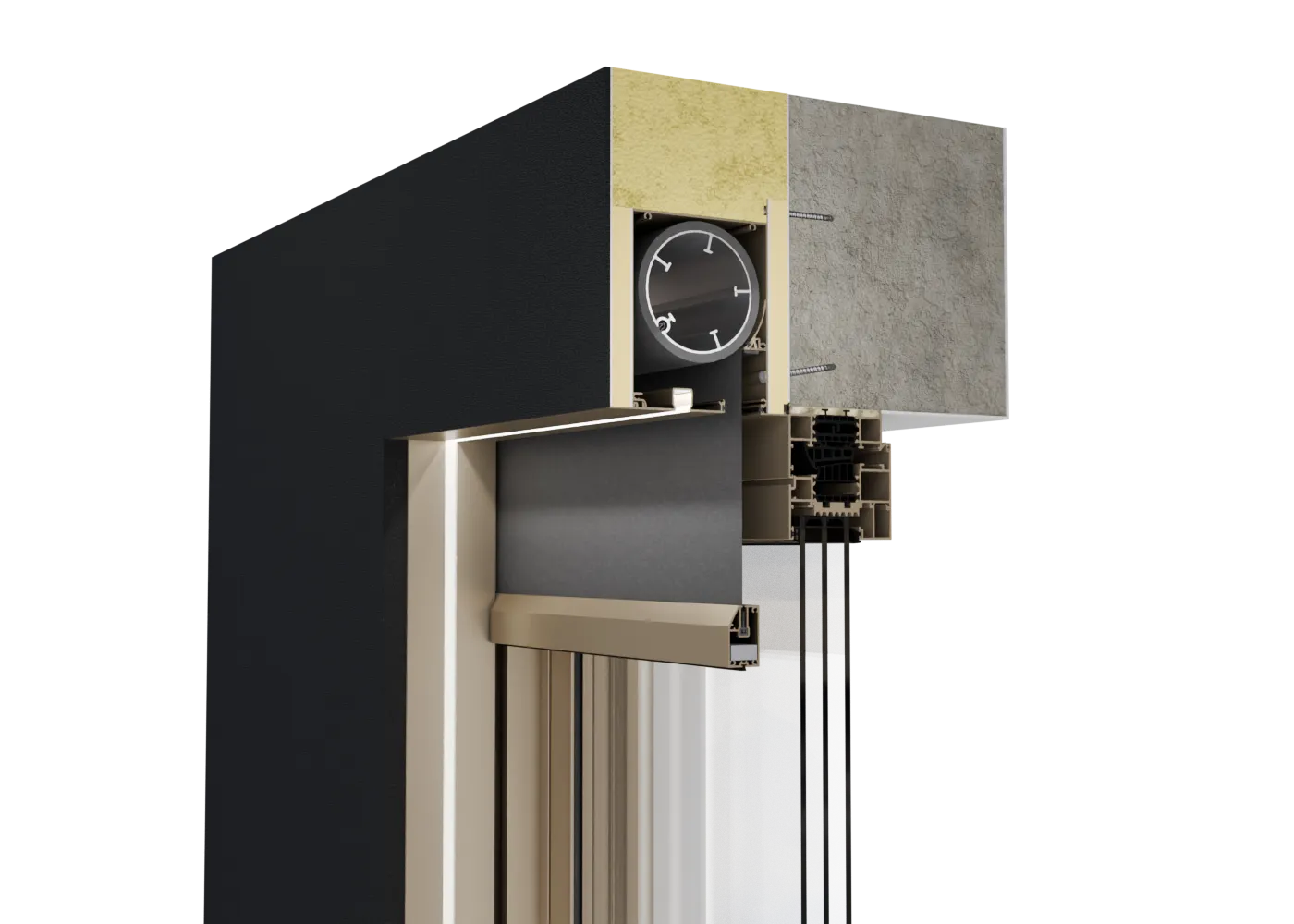

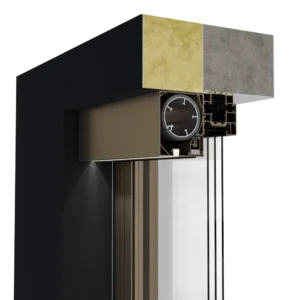

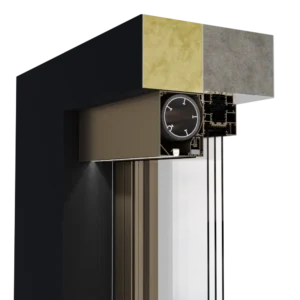

WS 130 A7 LED

WS 130 A7 LED

WS 130 A7 LED

WS 130 A7 LED ADAPTIVES SYSTEM WS 130 A7 LED

Kastengröße: 130 x 160 mm

LED-Beleuchtung: Integrierte lineare LED-Beleuchtung im Kasten

Maximale Systemmaße: 7000 x 3400 mm \[23,80 m²] oder 5400 x 6000 mm \[32,40 m²]

Rohrdurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Untere Leiste: LD-2 (schiebt sich vollständig in den Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

EINZELFÜHRUNG ZIP: P3

EINZELFÜHRUNG ZIP: P4

EINZELFÜHRUNG ZIP: Z2

EINZELFÜHRUNG ZIP: Z5

STAHLSEIL

FREIHÄNGENDE ROLLLADE

LISTWY DOLNE

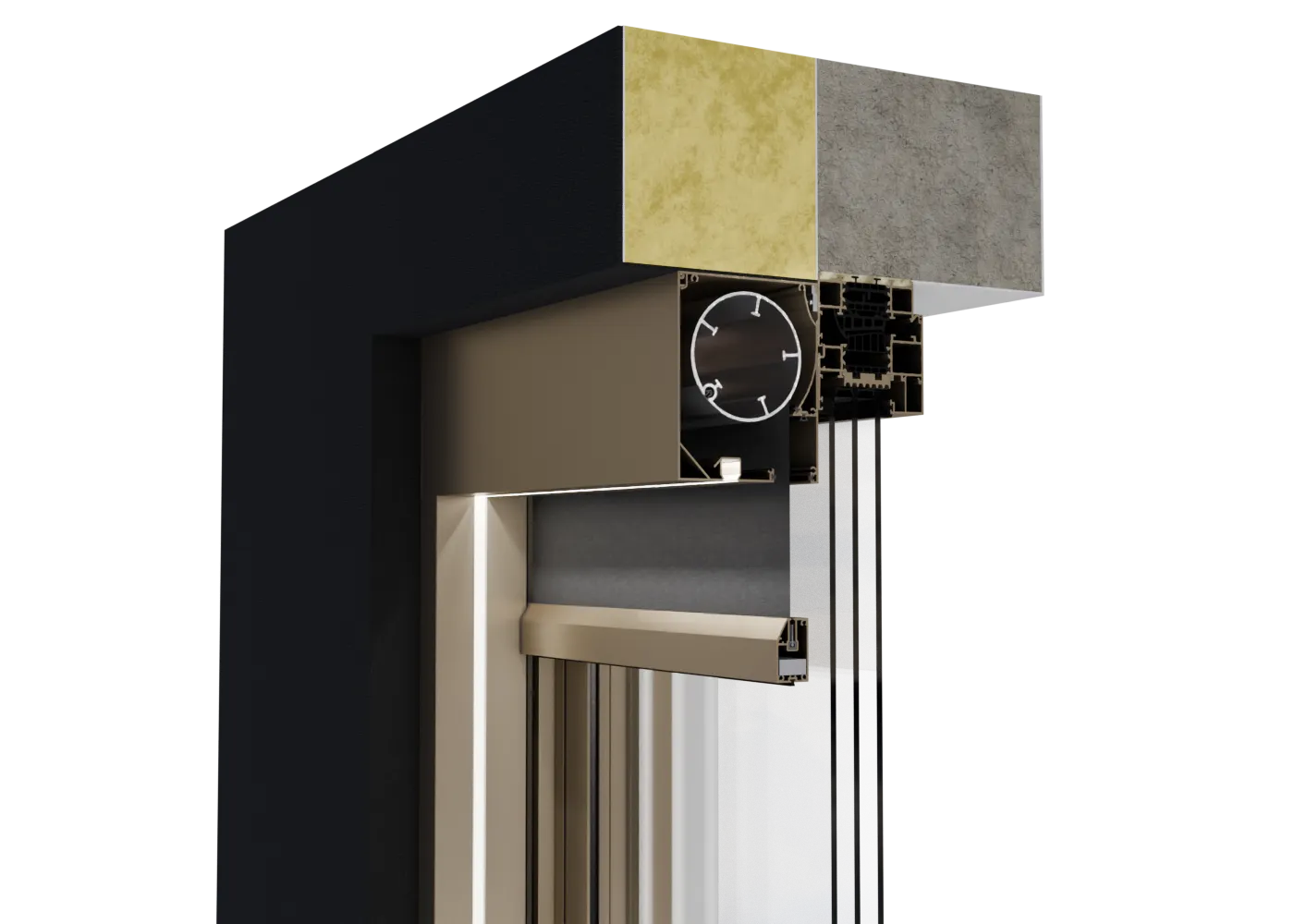

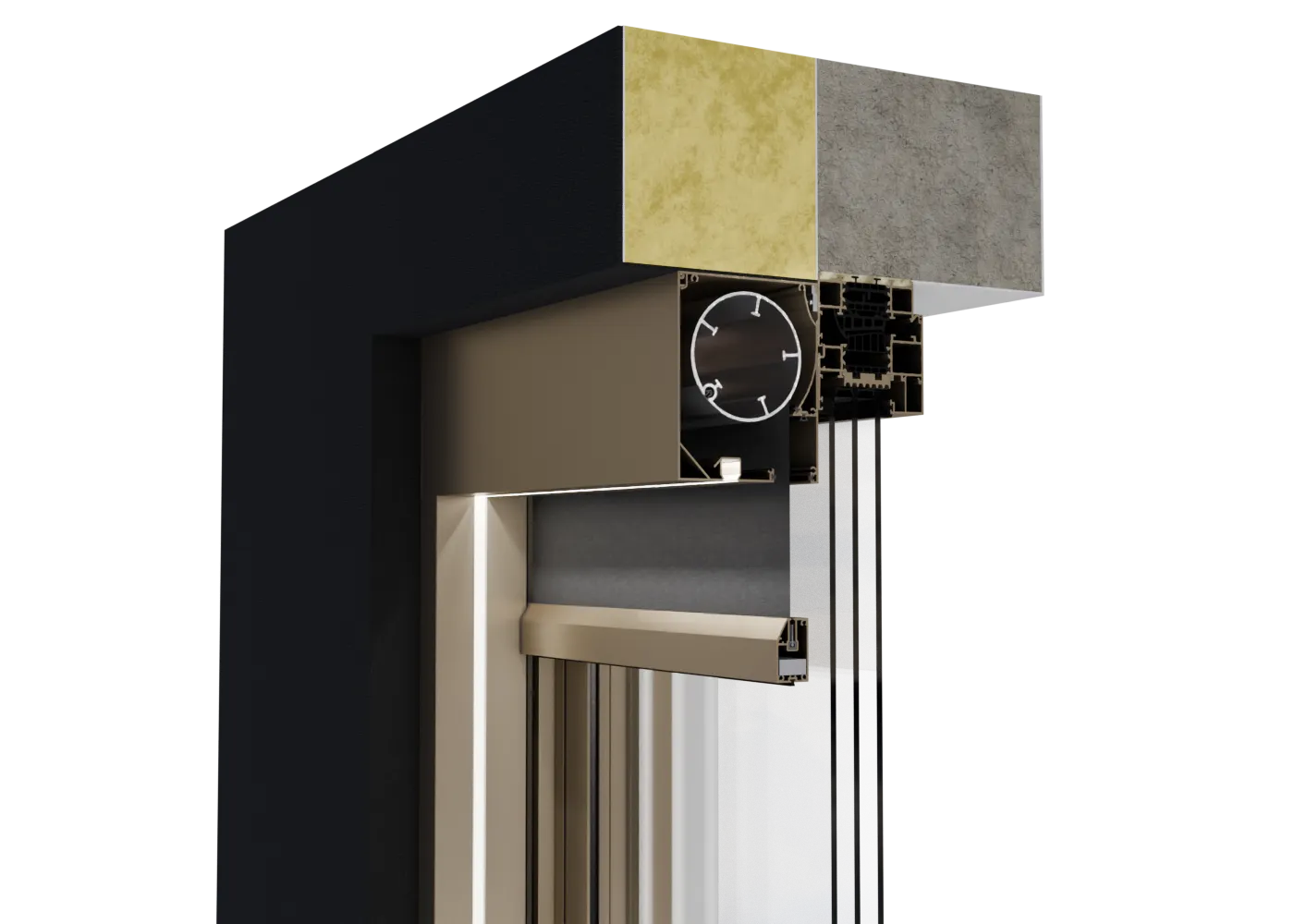

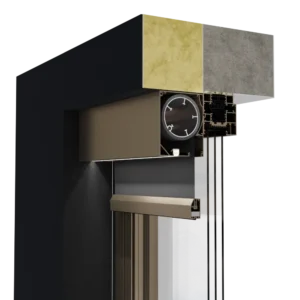

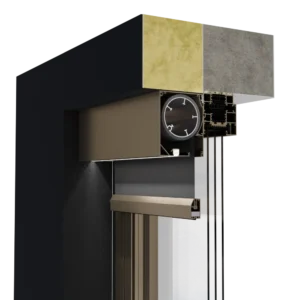

WS 130 A8 LED – MIT HALTERUNG

WS 130 A8 LED – MIT HALTERUNG

WS 130 A8 LED – MIT HALTERUNG

WS 130 A8 LED – MIT HALTERUNG ADAPTIVES SYSTEM WS 130 A8 LED, MIT HALTERUNG

Kastengröße: 130 x 160 mm

LED-Beleuchtung: Integrierte lineare LED-Beleuchtung im Kasten

Maximale Systemmaße: 7000 x 3400 mm \[23,80 m²] oder 5400 x 6000 mm \[32,40 m²]

Rohrdurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Untere Leiste: LD-2 (schiebt sich vollständig in den Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNG ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNG ZIP: P2

EINZELFÜHRUNG ZIP: P3

EINZELFÜHRUNG ZIP: P4

EINZELFÜHRUNG ZIP: Z2

EINZELFÜHRUNG ZIP: Z5

STAHLSEIL

FREIHÄNGENDE ROLLLADE

UNTERLEISTEN

UNTERLEISTE LD-2

MONTAGEHALTERUNGEN

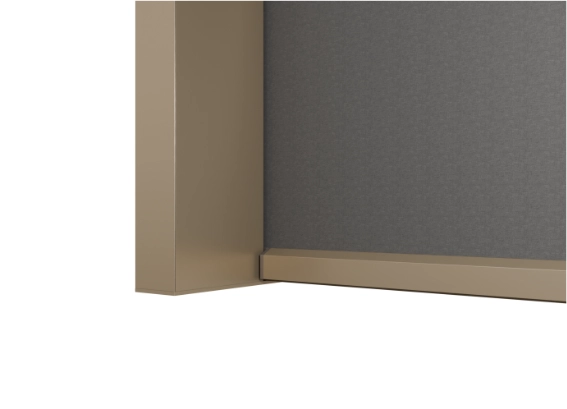

SYSTEMSCHLÖSSER „CLICK“

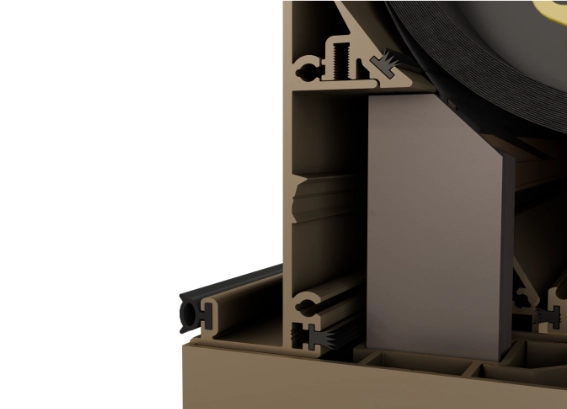

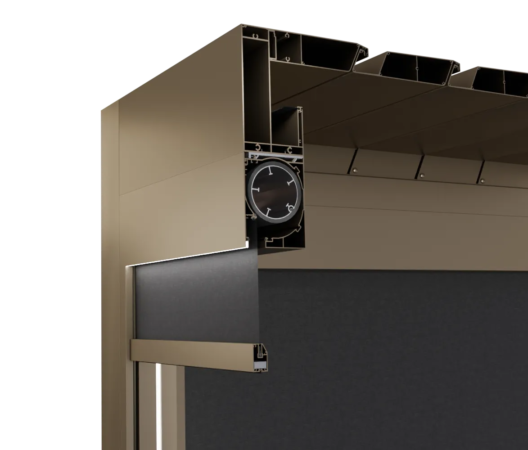

Im Gegensatz zu den Standardlösungen, bei denen Kasten und Klappe dauerhaft mit Nieten oder Schrauben verbunden sind, ermöglicht das System ein schnelles und werkzeugloses Verbinden und Trennen der Elemente. Die eingesetzten CLICK-Verbindungen wurden mit dem Ziel entwickelt, eine hohe Dauerhaftigkeit und Stabilität der Verbindung zu gewährleisten. Zusätzlich wurde die Verbindungskante zwischen Kasten und Revisionsklappe an die Ecke des Kastenprofils verlegt, sodass die Fuge praktisch unsichtbar bleibt und das gesamte System ein einheitliches und ästhetisches Erscheinungsbild erhält.

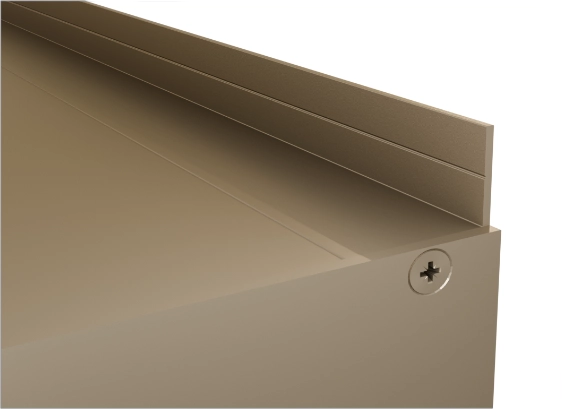

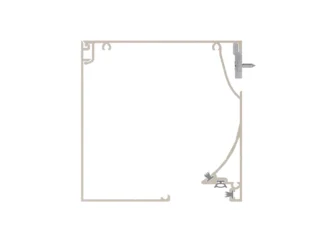

INNOVATIVE KONSTRUKTION DER REVISIONSKLAPPE „CLICK“

Die Revisionsklappe ist mit präzise konstruierten Schnappschlössern ausgestattet, die ein schnelles und sicheres Einsetzen in den Wickelkasten ermöglichen. Die gesamte Montage erfolgt ohne den Einsatz von Schrauben oder Nieten, wodurch zusätzliches Bohren und mechanische Befestigung entfallen. Dadurch zeichnet sich das System durch maximale Ästhetik aus – das Fehlen sichtbarer Befestigungselemente sorgt dafür, dass die gesamte Einheit als homogene, stimmige Struktur erscheint. Ein weiterer Vorteil ist die einfache Wartung – die Klappe kann jederzeit herausgelöst und wieder eingesetzt werden, ohne dass dabei der Kasten oder der Rollladenmechanismus beschädigt wird.

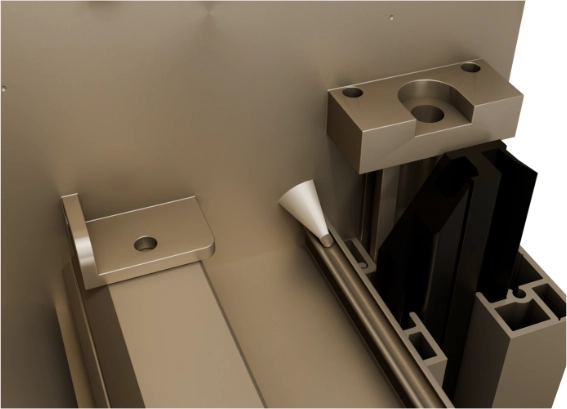

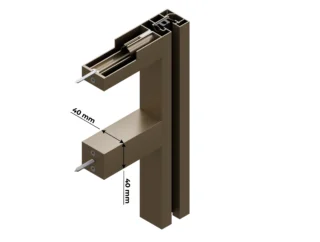

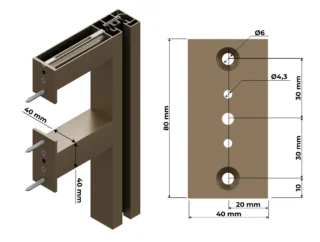

SYSTEM-ABSTÄNDE DER FÜHRUNGSSCHIENEN

Die systemischen Distanzstücke der ZIP-Führungsschienen sind präzise entwickelte Montageelemente, die eine ästhetische und funktionale Absetzung der Führungsschienen sowie der ZIP-Rollläden von der Montagefläche ermöglichen. Sie stellen eine integrale Komponente des gesamten Systems dar und gewährleisten nicht nur eine solide Befestigung, sondern bringen zudem eine Reihe technologischer Lösungen ein, die herkömmliche Distanzstücke in konkurrierenden Systemen deutlich übertreffen.

OBERES PROFIL MIT GEWEBE VERSCHWEISST

Der Einsatz eines profilierten Montageprofils, das mit der oberen Stoffkante verschweißt ist, stellt eine Lösung dar, die die herkömmliche Stofftasche für Einlagen eliminiert, die Montage vereinfacht und den Service erleichtert. Durch die Möglichkeit, den Stoff ohne Demontage der Wickelwelle ein- und auszuklicken, bietet dieses System eine schnellere Handhabung, eine längere Lebensdauer des Stoffes sowie eine höhere Ästhetik. Zudem sorgt die optimierte Profilgeometrie für die Beseitigung des Problems von Abdrücken im Stoff, wodurch sich diese Lösung deutlich von klassischen ZIP-Screen-Systemen abhebt.

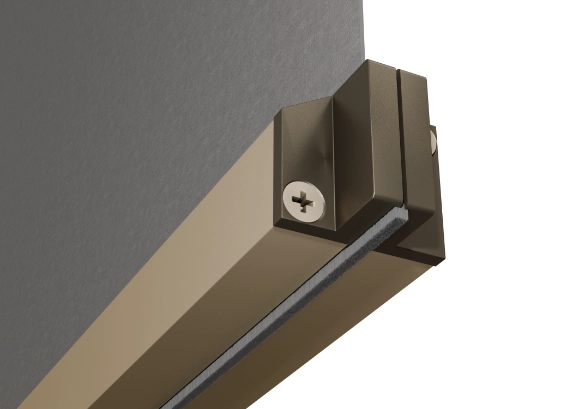

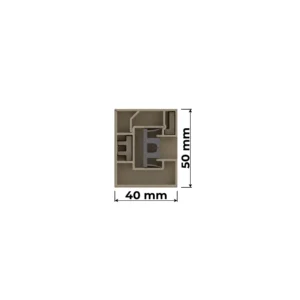

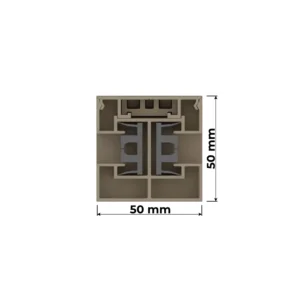

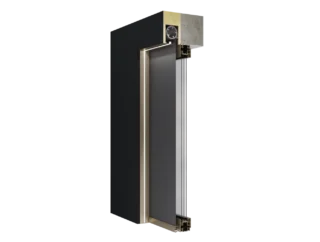

FÜHRUNGSSCHIENE SLIM

Die ZIP SLIM-Führungsschiene wurde speziell für den kleinsten Adaptivkasten entwickelt, um sich proportional an dessen kompakte Abmessungen anzupassen und mit ihm eine stimmige, minimalistische Form zu bilden. Die aus stranggepresstem Aluminium gefertigte Führungsschiene wird mithilfe des CLICK-Schnappsystems mit dem Abschlussprofil verbunden, wodurch der Einsatz von Schrauben entfällt und vollkommen unsichtbare Verbindungen gewährleistet werden. Dadurch erfolgt die Montage schneller und die Ästhetik der Verkleidung bleibt auf höchstem Niveau. Die SLIM-Führungsschiene ist eine Lösung, die für Projekte geschaffen wurde, bei denen Kompaktheit, klare Formensprache und hohe Funktionalität im Vordergrund stehen.

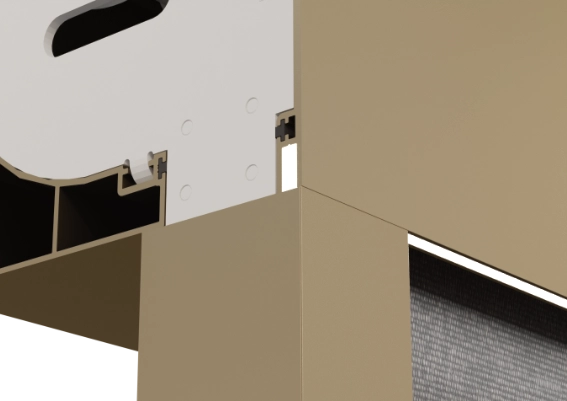

SYSTEM CLICK DER ZIP-FÜHRUNGSSCHIENEN

Das CLICK-System in den ZIP-Führungsschienen ist eine innovative Lösung, die eine schraubenlose Verbindung des Führungsschienenprofils mit dem Abschlussprofil ermöglicht. Dank des Schnappmechanismus erfolgt die Montage schnell, präzise und ohne Bohren oder Schrauben, wodurch sichtbare Befestigungselemente entfallen und die Ästhetik des gesamten Systems deutlich verbessert wird. Diese Lösung erleichtert zudem den Service und die Demontage, ohne das Risiko einer Beschädigung der Fassade oder der Führungsschiene.

Die Lösung besteht aus zwei Materialien mit unterschiedlicher Dichte – das eine sorgt für eine stabile Position in der Führungsschiene, während das andere, flexiblere, den Stoff im Rollladen gleichmäßig spannt und so Wellenbildung und Falten verhindert.

BELEUCHTUNG IN GROSSEN ZIP-FÜHRUNGSSCHIENEN

Die LED-Beleuchtung in den großen ZIP-Führungsschienen wurde im Inneren des Profils in einem speziell entwickelten Revisionsraum integriert. Diese Lösung ermöglicht eine gleichmäßige Ausleuchtung der gesamten Stoffhöhe des Rollladens und sorgt für einen ästhetischen Lichteffekt in der Nische oder im Nutzungsbereich, z. B. unter einer Pergola. Die Beleuchtung ist hinter einer Abdeckung verborgen, was ein elegantes Erscheinungsbild ohne sichtbare Lichtquellen gewährleistet.

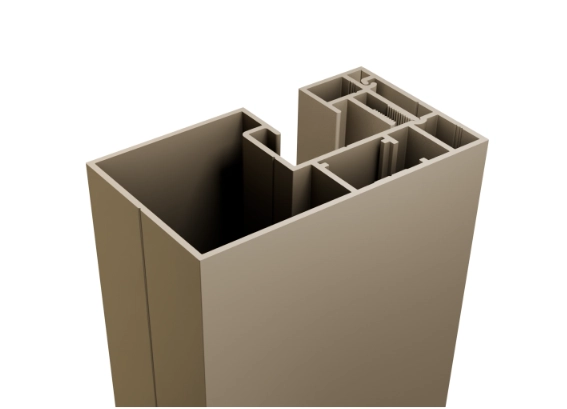

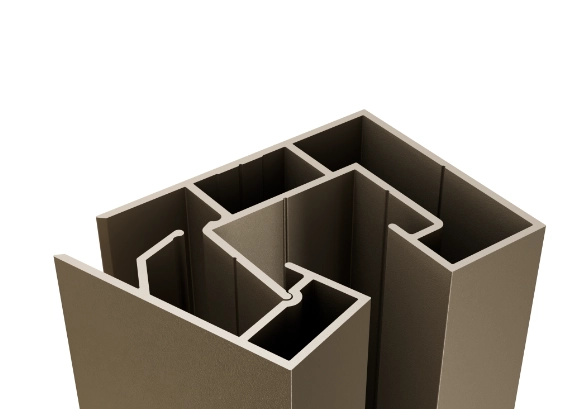

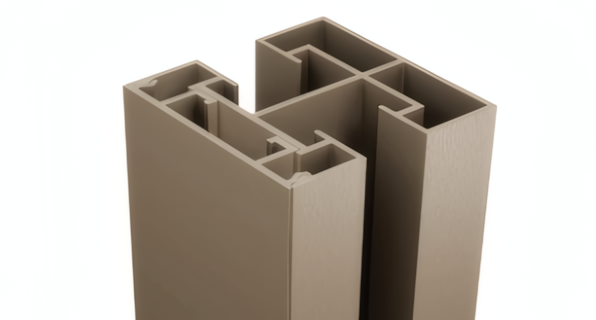

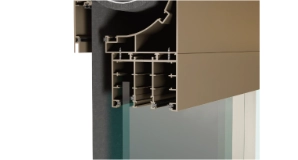

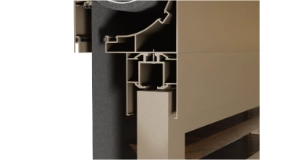

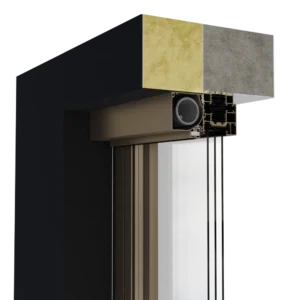

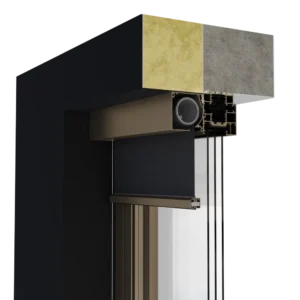

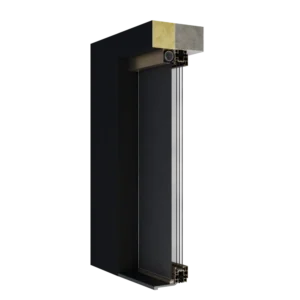

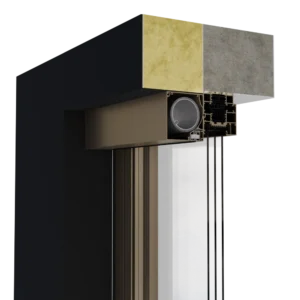

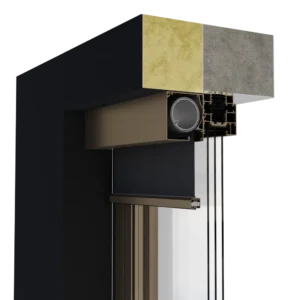

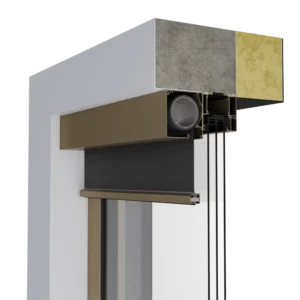

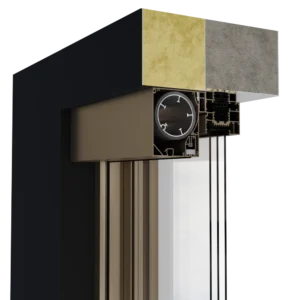

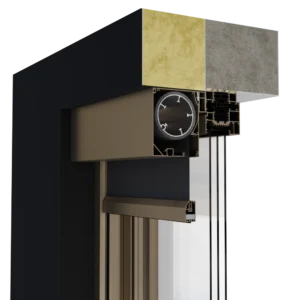

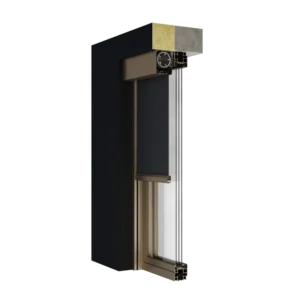

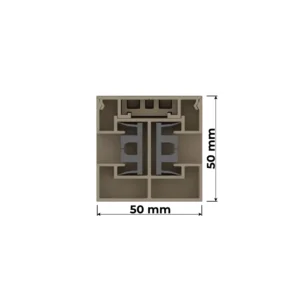

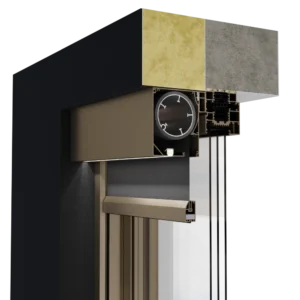

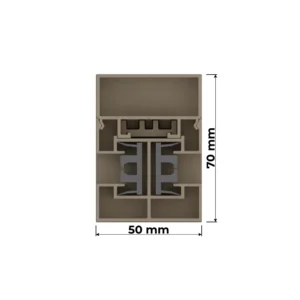

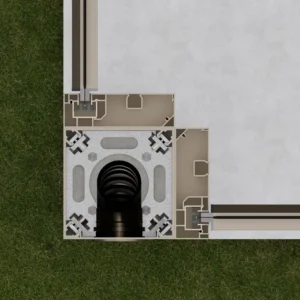

DOPPELFÜHRUNGSSCHIENE

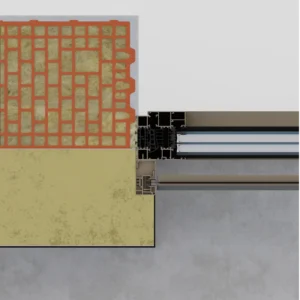

Die Doppelführungsschiene mit Distanzstück ist eine speziell entwickelte ZIP-Führungsschiene für Unterputzsysteme, die die Montage von zwei oder mehr Rollläden in einer einzigen Öffnung ermöglicht, z. B. bei HS-Fenstern mit Mittelpfosten.

Dank der optimalen Abmessungen passt sich die Führungsschiene an die meisten Pfosten in Fenstersystemen an, was ein ästhetisches Erscheinungsbild und eine stimmige Integration in die Fassade gewährleistet. Das eingesetzte Distanzstück sorgt für eine präzise Anpassung an das Unterputzsystem.

Es handelt sich um eine praktische und elegante Lösung, die eine funktionale Aufteilung der Sonnenschutzanlagen ermöglicht, dabei jedoch ein minimalistisches Design und eine hohe Verarbeitungsqualität beibehält.

DOPPELFÜHRUNGSSCHIENE MIT DISTANZSTÜCK

Die Doppelführungsschiene mit Distanzstück ist eine speziell entwickelte ZIP-Führungsschiene für Adaptiv- und Unterputzsysteme, die die Montage von zwei oder mehr Rollläden in einer einzigen Öffnung ermöglicht, z. B. bei HS-Fenstern mit Mittelpfosten.

Dank der optimalen Abmessungen passt sich die Führungsschiene an die meisten Pfosten in Fenstersystemen an, was ein ästhetisches Erscheinungsbild und eine stimmige Integration in die Fassade gewährleistet. Das eingesetzte Distanzstück ermöglicht das Absetzen des Rollladens vom Fenster oder von der Fassade.

Es handelt sich um eine praktische und elegante Lösung, die eine funktionale Aufteilung der Sonnenschutzanlagen ermöglicht, dabei jedoch ein minimalistisches Design und eine hohe Verarbeitungsqualität beibehält.

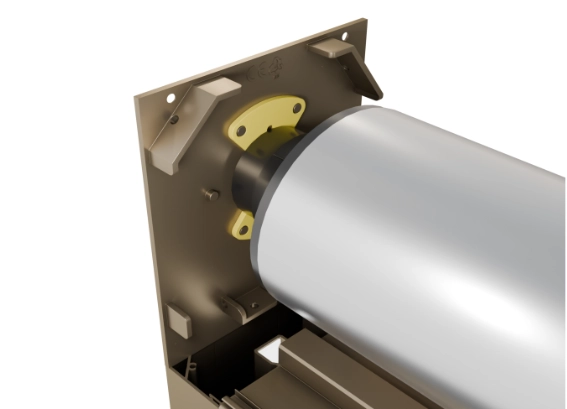

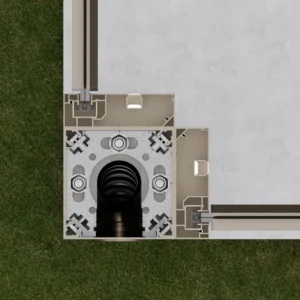

MONTAGEÖFFNUNGEN

Die Montageöffnungen für die Verkabelung wurden so konzipiert, dass eine schnelle und komfortable Führung der Stromkabel für Antrieb oder Beleuchtung möglich ist, wodurch der Bedarf an zusätzlicher Bearbeitung während der Installation minimiert wird. Ihre optimale Anordnung gewährleistet eine sichere und ästhetische Verlegung der Kabel, was nach Abschluss der Montage zu einem ordentlichen Erscheinungsbild des Systems führt.

Die Öffnungen sind an mehreren Stellen im aus Aluminium gegossenen Seitenteil des Rollladens vorbereitet, was eine flexible Wahl der Kabelführung für den Antrieb ermöglicht und die Installation an die individuellen Montagebedingungen anpasst.

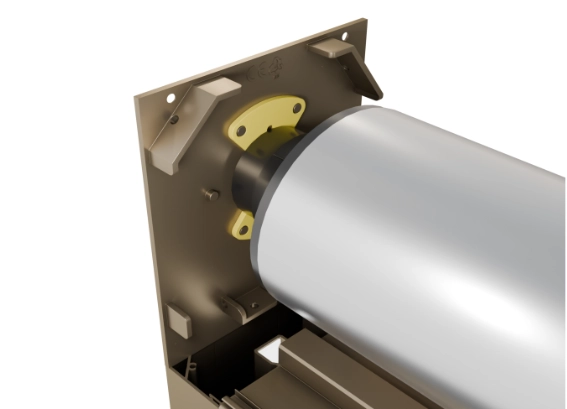

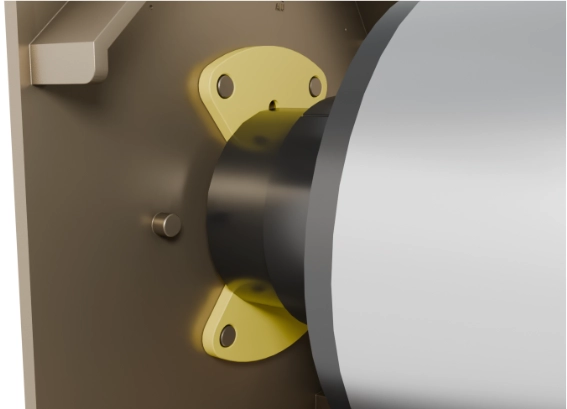

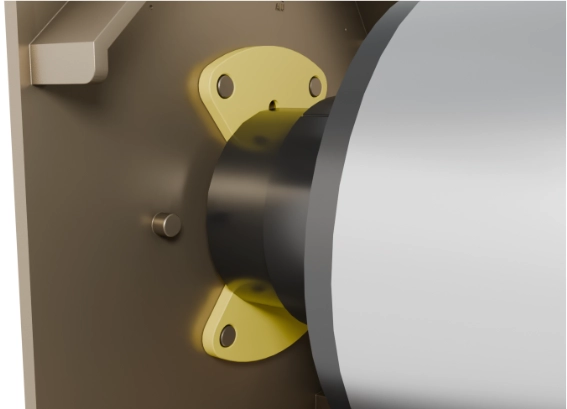

UNIVERSELLE ANTRIEBSBEFESTIGUNGEN

Die Antriebsbefestigung ermöglicht dank ihrer durchdachten Konstruktion eine schnelle und unkomplizierte Montage sowie Demontage des Antriebs – unabhängig von den spezifischen Installationsbedingungen.

Das Befestigungssystem zeichnet sich durch eine solide und stabile Lagerung des Antriebs aus, was einen zuverlässigen Betrieb des Rollladens gewährleistet. Darüber hinaus erlaubt die Befestigung eine axiale Drehung des Antriebs in 60-Grad-Schritten, was sowohl für die freie Kabelführung des Rollladenantriebs als auch für den komfortablen Zugang zu den mechanischen Endlagen des Antriebs von Bedeutung ist.

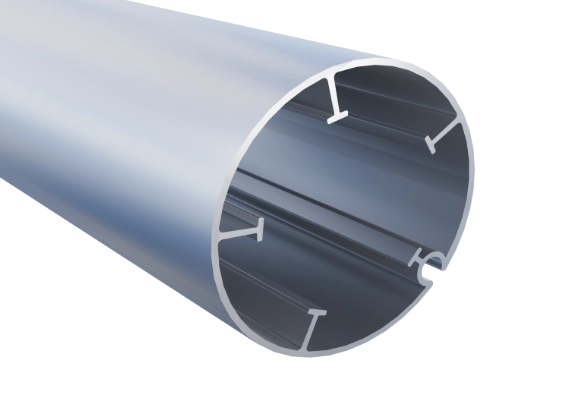

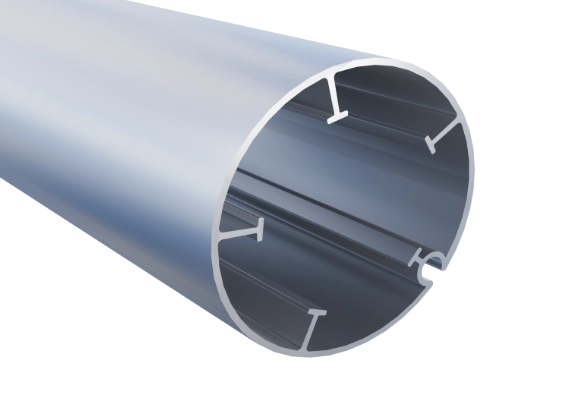

4 WICKELWELLENDURCHMESSER MIT DEKORPROFIL

Im System wurden vier Wickelwellendurchmesser eingesetzt:

Ø 63 mm, Ø 78 mm, Ø 85 mm – Stahlwickelwellen, die eine hohe Festigkeit und Verformungsbeständigkeit gewährleisten, ideal für Standard- und mittelgroße Rollläden.

Ø 100 mm – systemische Aluminiumwelle aus der Legierung 6063 T6, vorgesehen für Rollläden mit großen Abmessungen.

Jede dieser Wellen ist mit speziellen Stoffprofilen kompatibel, die eine Montage oder einen Austausch ermöglichen, ohne dass die Wickelwelle aus dem Rollladen demontiert werden muss. Dadurch wird die Wartung sowie die Anpassung des Rollladens an neue Nutzungsbedingungen schnell und komfortabel, ohne in die gesamte Konstruktion des Rollladens eingreifen zu müssen.

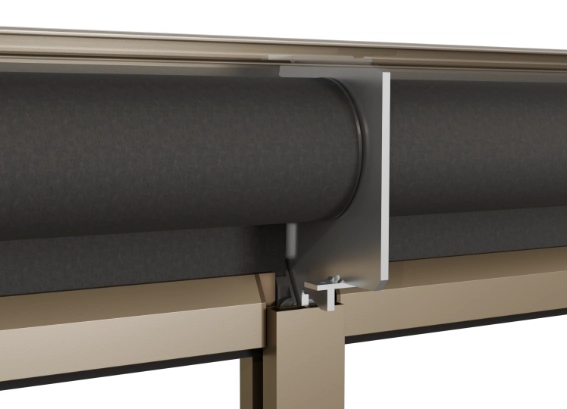

STAHLTEILUNGEN DER ANLAGEN

Die Stahlteilungen der Anlagen sind robuste und präzise konstruierte Elemente, die bei der Doppelführungsschiene mit Distanzstück eingesetzt werden. Ihre Hauptfunktion besteht darin, zwei unabhängige Rollläden in einem System stabil zu positionieren und voneinander zu trennen, z. B. bei Unterputzlösungen für HS-Fenster mit Mittelpfosten.

Gefertigt aus hochfestem Stahl, gewährleisten diese Teilungen eine solide Befestigung sowohl für die Rollladenantriebe als auch für die Lager der Wickelwellen. Durch diese Lösung bleibt das gesamte System stabil, funktionssicher und langlebig – selbst bei großformatigen Beschattungen.

Es handelt sich um eine zuverlässige Lösung, die die Funktionalität von ZIP-Systemen erhöht und eine sichere Montage sowie eine lange Lebensdauer der Konstruktion garantiert.

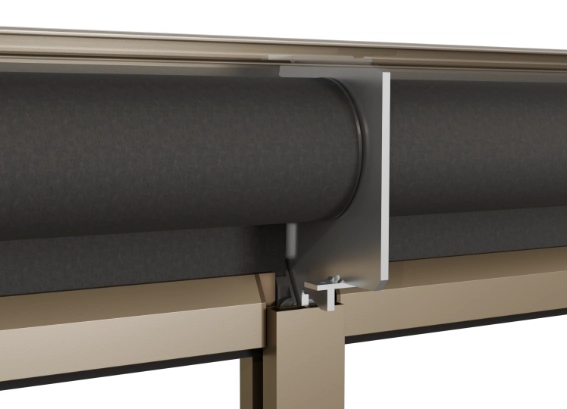

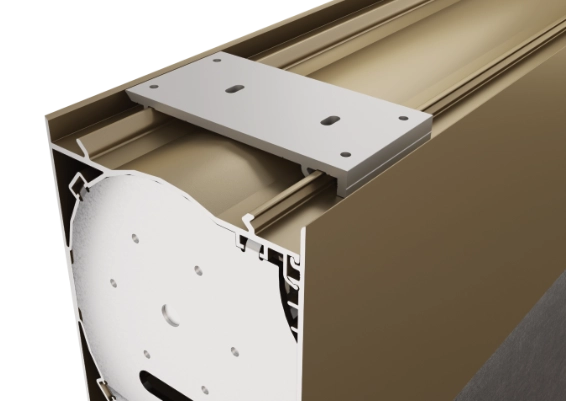

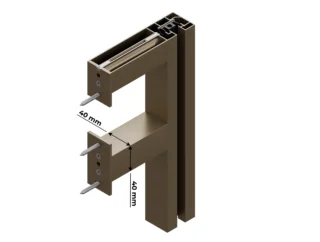

MONTAGEHÄNGER

Der Montagehänger aus stranggepresstem Aluminium ist eine innovative Lösung für die Montage von adaptiven Rollladenkästen. Er ermöglicht eine schnelle, komfortable und ästhetische Befestigung an unterschiedlichen Oberflächen – Fensterrahmen, Fassaden oder Gebäudewänden – ohne dass die Wickelwelle mit dem aufgewickelten Stoff demontiert werden muss.

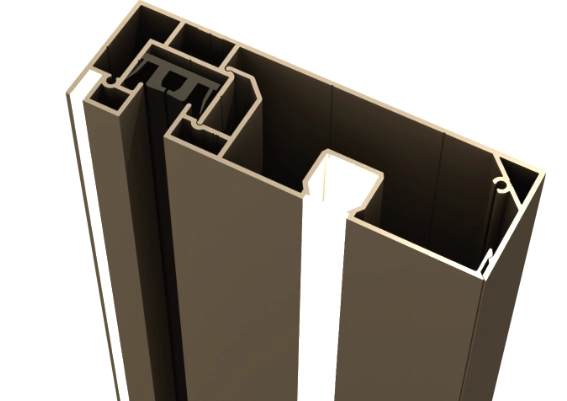

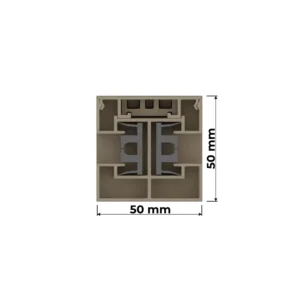

FÜHRUNGSSCHIENEN-ABSTÄNDE

Die Distanzstücke bestehen aus einem hochwertigen stranggepressten Aluminiumprofil, dessen Querschnitt so entwickelt wurde, dass er perfekt zum Querschnitt der ZIP-Führungsschiene passt. Das bedeutet, dass die Abmessungen des Distanzstücks exakt mit den Maßen der Führungsschiene übereinstimmen. Eine solche Konstruktion garantiert eine hohe mechanische Festigkeit, Verformungsbeständigkeit sowie Maßgenauigkeit, während die mechanische Verbindung zwischen Distanzstück und Führungsschiene im Inneren verborgen bleibt.

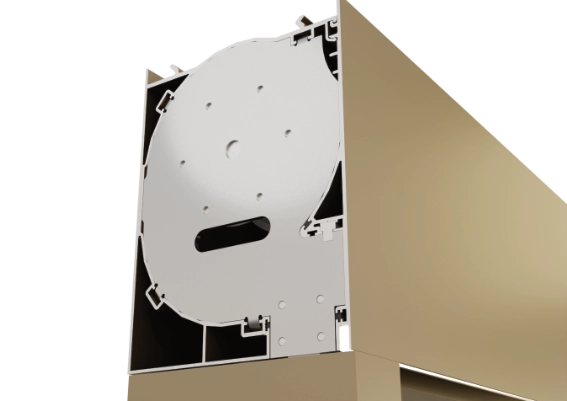

GUSSSEITENTEILE AUS ALUMINIUM

Die gegossenen Aluminium-Seitenteile wurden präzise so konstruiert, dass sie in verschiedenen Systemvarianten eingesetzt werden können und dabei Stabilität, Langlebigkeit sowie volle Funktionalität gewährleisten. Die Seitenteile verfügen über systemische Befestigungen für die Stromkabel des Antriebs sowie zusätzliche Markierungen, die das präzise Anbringen der Öffnungen für die Kabelausführung des Rollladenantriebs erleichtern. Zudem sind die Seitenteile mit dem CLICK-System zum Verriegeln der Revisionsklappen ausgestattet, ohne dass ein Bohren erforderlich ist.

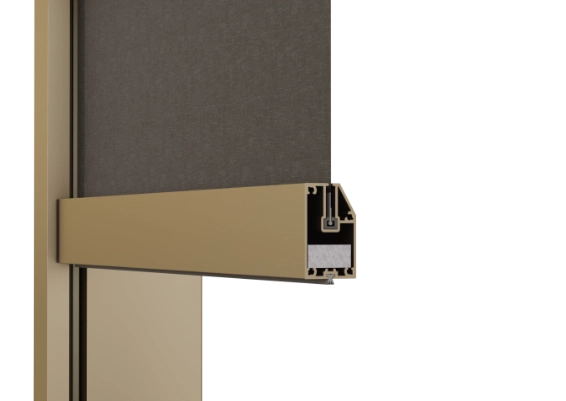

UNTERLEISTEN

Das Screen-Rollladensystem wurde mit unteren Abschlussleisten ausgestattet, die den Stoff in mehreren Größen beschweren und so unterschiedlichen ästhetischen und technischen Anforderungen gerecht werden. Jede von ihnen gewährleistet die Stabilität des Stoffes, dessen gleichmäßige Spannung sowie einen reibungslosen Lauf des Rollladens.

VERDECKTE SCHWEISSNAHT DER UNTERLEISTE

Die Unterleiste mit verdeckter Stoffschweißnaht ist ein ausgereiftes Element des Sonnenschutzsystems, das eine vollständige Verdeckung der Verbindungsstelle von Stoff und ZIP-Reißverschluss ermöglicht. Dank der speziellen Konstruktion der Leiste werden der Reißverschluss zusammen mit dem Stoff und dem PVC-Zwischenprofil im Inneren aufgenommen, was die Ästhetik des Rollladens verbessert und sichtbare Verbindungen eliminiert. Diese Lösung erleichtert zudem die Wartung des Systems, insbesondere beim Austausch des Stoffes.

ALUMINIUM-WICKELWELLE 100 mm

Die systemische Aluminium-Wickelwelle mit einem Durchmesser von 100 mm ist ein Schlüsselelement für großformatige Anlagen und gewährleistet eine hohe Festigkeit sowie einen stabilen Betrieb des Systems. Sie wird aus der Aluminiumlegierung 6063 T6 gefertigt und zeichnet sich durch eine geringe Durchbiegung aus. Damit stellt sie ein zentrales Bauteil für großdimensionierte Systeme dar, das durch seine vorteilhaften Eigenschaften, insbesondere die niedrige Durchbiegung, überzeugt.

Dank der präzisen Verarbeitung ermöglicht die Welle ein gleichmäßiges und flüssiges Aufwickeln des Stoffes, während eine spezielle Abstufung im Durchmesser Verformungen reduziert und so ein ästhetisches Erscheinungsbild sowie die Langlebigkeit des Materials sicherstellt. Darüber hinaus verwendet das System ein Stoffeinsteckprofil, das einen Austausch des Stoffes ermöglicht, ohne die Welle aus dem Rollladen ausbauen zu müssen, was die Wartung und Instandhaltung erheblich erleichtert.

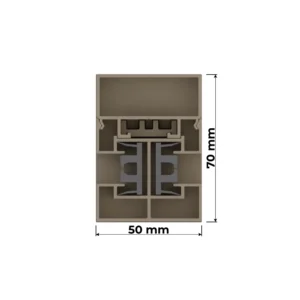

ZIP-EINSATZ

Der ZIP-Einsatz ist eine moderne Lösung im System, die maximale Stabilität und ein gleichmäßiges Führen des Stoffes gewährleistet. Durch den Einsatz der ZIP-Reißverschlusstechnologie wird das Material gleichmäßig gespannt und über die gesamte Höhe in den Führungsschienen gehalten, was sowohl Windbeständigkeit als auch das Fehlen von Spiel an den Stoffkanten garantiert.

Der Einsatz besteht aus zwei Materialien mit unterschiedlicher Dichte – das eine sorgt für eine stabile Position in der Führungsschiene, während das andere, flexiblere, den Stoff im Rollladen gleichmäßig spannt und so Wellenbildung und Falten verhindert.

VERDECKTE UNTERLEISTE

Im Adaptivsystem wurde eine verdeckte Unterleiste eingesetzt, die für ein ästhetisches und harmonisches Finish des Rollladens sorgt. Die Unterleisten sind in mehreren Größen erhältlich, abhängig von der Kastengröße oder der jeweiligen Anwendung. Dank der durchdachten Konstruktion verschwindet die Leiste beim Hochfahren vollständig im Rollladenkasten, sodass sich das System minimalistisch und elegant präsentiert – ohne sichtbare untere Elemente.

Diese Lösung gewährleistet ein einheitliches Erscheinungsbild der gesamten Anlage und macht das System zur idealen Wahl für moderne Fassaden und Gebäudefronten, bei denen Ästhetik und hohe Verarbeitungsqualität im Vordergrund stehen.

GLEITPROFIL

Das Gleitprofil für den Stoff mit integrierter Bürstendichtung ist ein Element im Inneren des Kastens, das für die Stabilisierung und die korrekte Führung des Stoffes verantwortlich ist. Seine Aufgabe besteht darin, das Material in der richtigen Position zu halten und so einen reibungslosen und störungsfreien Lauf des Rollladens zu gewährleisten.

Durch den Einsatz der Bürstendichtung minimiert das Profil die Reibung des Stoffes, schützt diesen vor Beschädigungen und verlängert seine Lebensdauer. Zudem wirkt die Dichtung dämpfend, reduziert Geräusche und verbessert die Dichtheit des gesamten Systems. Diese Lösung garantiert einen präzisen und leisen Betrieb und steigert damit den Komfort sowie die Zuverlässigkeit des Sonnenschutzsystems.

ABDECKKAPPEN DER UNTERLEISTEN

Die Abdeckkappen der Unterleiste wurden mit präzise geformten Nuten konstruiert, die die Linie der Bürstendichtungsnut in der Leiste selbst fortführen. Dadurch kann die Dichtung über die gesamte Breite des Rollladens – von Kappe zu Kappe – geführt werden, was die Entstehung von Spalten an den Kanten der Unterleiste verhindert. Diese Lösung sorgt für eine bessere Abdichtung des Rollladens in geschlossener Position und reduziert das Eindringen von Licht, Insekten und Verschmutzungen.

TECHNISCHER RAUM DER GROSSEN FÜHRUNGSSCHIENEN

Die große ZIP-Führungsschiene, die in Adaptivsystemen für Screen-Rollläden eingesetzt wird, wurde nicht nur für die Führung des Stoffes mit ZIP-Reißverschluss entwickelt, sondern auch als multifunktionales Element mit einem sogenannten technischen Raum. Dieser Raum bildet eine innere Arbeitskammer der Führungsschiene, die bereits in der Produktion oder bei der Montage zur Aufnahme zusätzlicher Installationselemente genutzt werden kann und so die Gebrauchstauglichkeit und die ästhetischen Eigenschaften des Systems deutlich steigert.

Die Unterleistenabdeckkappen wurden mit präzise geformten Nuten konstruiert, die die Linie der Bürstendichtungsnut in der Leiste selbst fortführen. Dadurch kann die Dichtung über die gesamte Breite des Rollladens – von Kappe zu Kappe – geführt werden, was die Entstehung von Spalten an den Kanten der Unterleiste verhindert. Diese Lösung sorgt für eine bessere Abdichtung des Rollladens in geschlossener Position und reduziert das Eindringen von Licht, Insekten und Verschmutzungen.

INTELLIGENTE STEUERUNG

Dank der Verwendung einer intelligenten Zentrale besteht die Möglichkeit, die Pergola sowie das zusätzliche Zubehör per Smartphone oder Tablet von jedem Ort der Welt aus zu steuern.

PREMIUM-MATERIALIEN

Innovative Konstruktion mit Dacheindeckung aus stranggepresstem Aluminium und Edelstahl. Die Profile sind aus hochwertigem Aluminium stranggepresst, mit dicken und robusten Wandungen, verstärkt durch Kammern und Versteifungen. Die in der WIN CLIMATIC-Konstruktion verwendeten Stahlelemente bestehen aus Edelstahl höchster Qualität mit starkem Querschnitt.

REICHE FARBPALETTE DER KONSTRUKTION IM STANDARD

Wir bieten eine reiche Farbpalette der Konstruktion bereits im Standard! Die Konstruktion wird pulverbeschichtet in sieben Farben aus der Standardpalette WIN CLIMATIC S500. Zusätzlich besteht die Möglichkeit einer Pulverbeschichtung in jeder beliebigen RAL-Farbe sowie in Holzdekorfarben.

KONFORMITÄT MIT CE-NORM

Unsere Produkte erfüllen die Anforderungen der Norm PN-EN 1090-1 bis PN-EN 1090-3, die vom Polnischen Komitee für Normung für Stahl- und Aluminiumkonstruktionen eingeführt wurde, was durch die CE-Kennzeichnung des Produkts bestätigt wird.

TIGER COATINGS

Dank des Einsatzes duroplastischer Pulverbeschichtungen erhalten wir nahezu unbegrenzte Möglichkeiten der Oberflächenveredelung. In unseren Produkten verwenden wir ausschließlich Beschichtungen von TIGER COATINGS, die Langlebigkeit und kompromisslose Verarbeitungsqualität gewährleisten.

DAUERHAFTE LACKBESCHICHTUNG

Alle von uns hergestellten Konstruktionen verfügen über ein internationales Zertifikat für die Qualität der Lackbeschichtungen. Mit dem QUALICOAT-Siegel ausgezeichnete Produkte zeichnen sich durch hervorragende Eigenschaften aus, die von akkreditierten Prüflaboren bestätigt wurden.

HOHE QUALITÄT DER PRODUKTAUSFÜHRUNG UND VERPACKUNG

Ein spezialisiertes Team sowie ein hochmoderner Maschinenpark ermöglichen es uns, höchste Produktionsqualität zu erreichen. Jedes Produkt wird vor dem Versand von der Qualitätskontrolle sorgfältig auf Übereinstimmung mit der Bestellung sowie auf die Verarbeitungsqualität geprüft. Großen Wert legen wir außerdem auf eine sorgfältige Verpackung und Sicherung der Ware für den Transport. Durch den Einsatz speziell angepasster Styroporformteile, Luftpolstermatten sowie stabiler, robuster Kartons können wir gewährleisten, dass die bestellte Ware in einwandfreiem Zustand bei Ihnen ankommt.

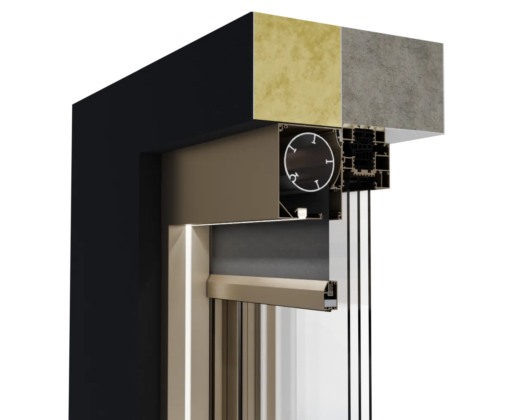

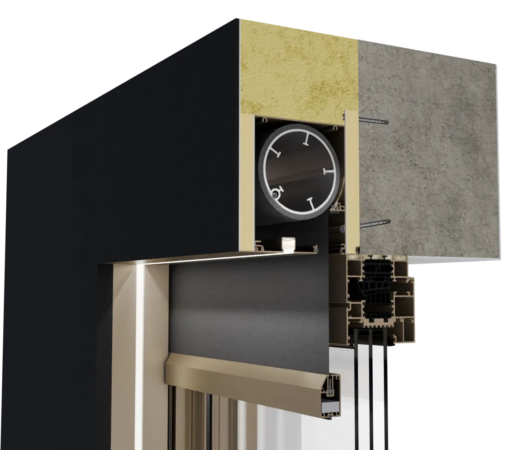

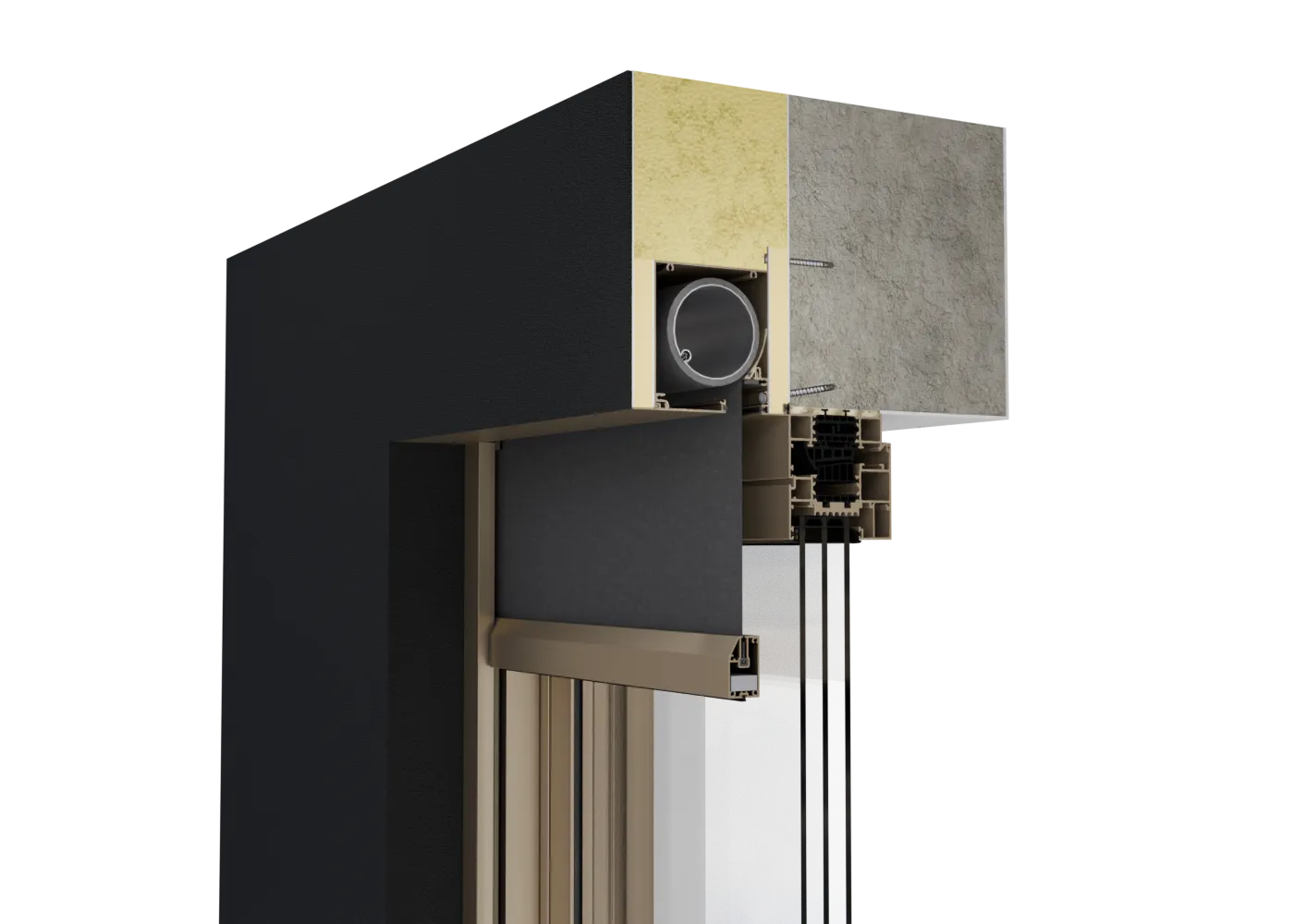

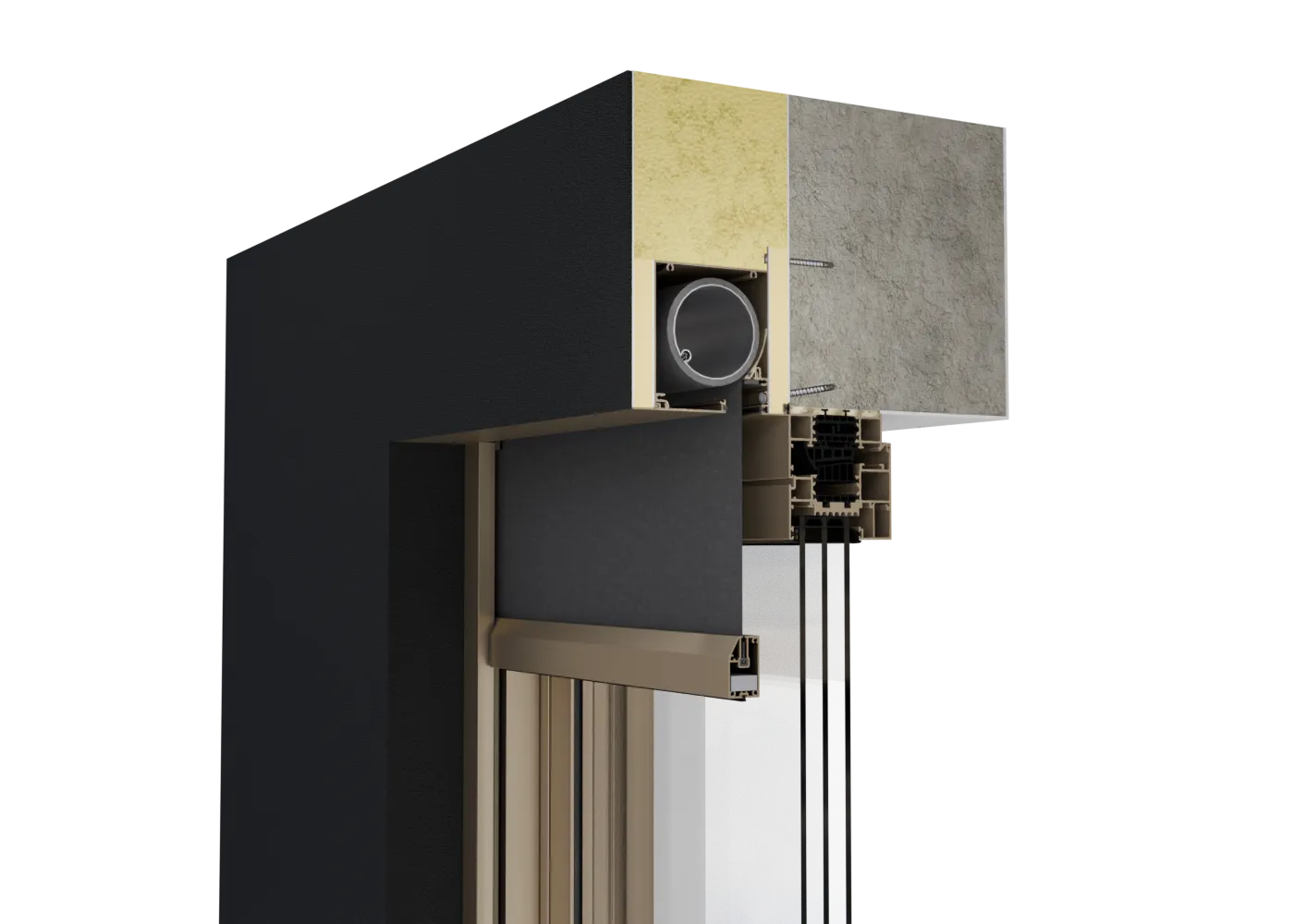

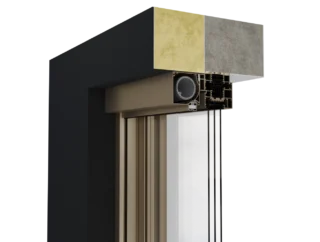

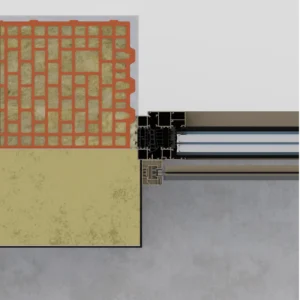

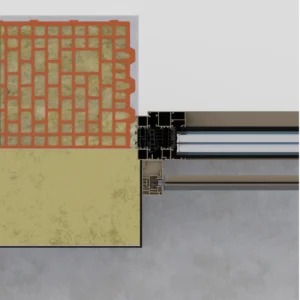

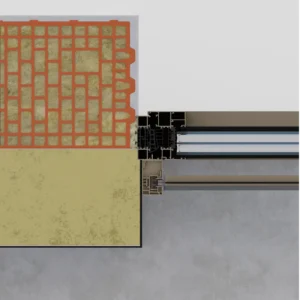

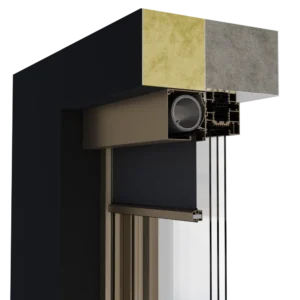

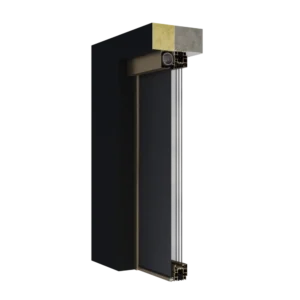

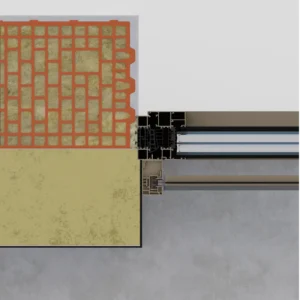

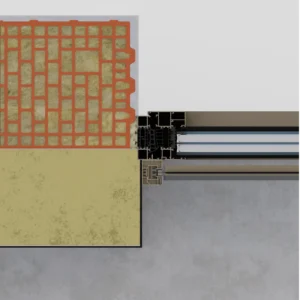

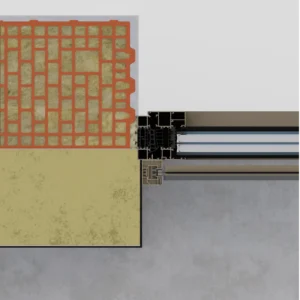

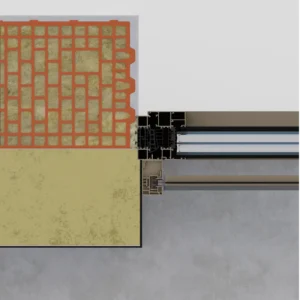

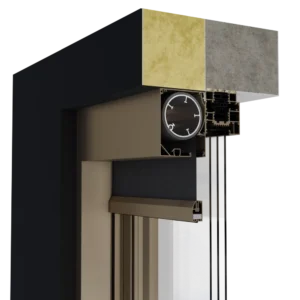

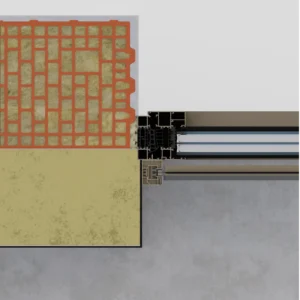

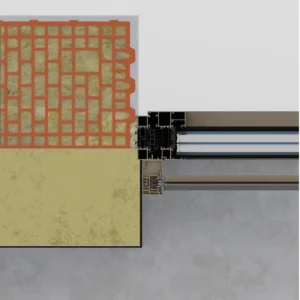

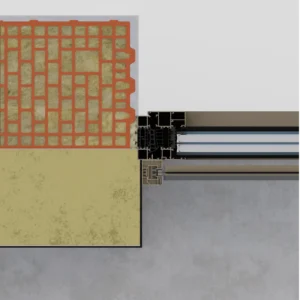

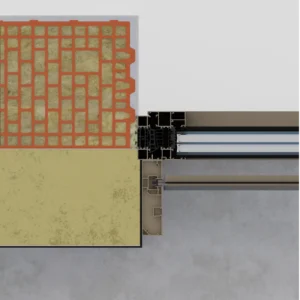

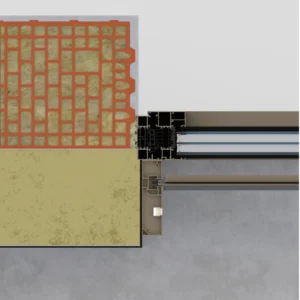

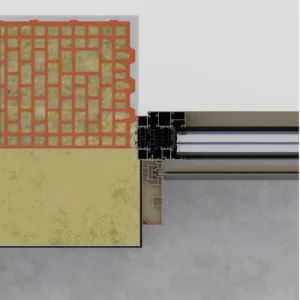

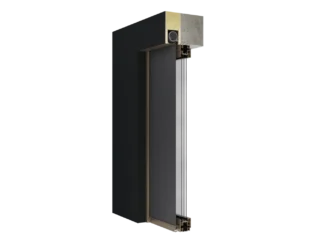

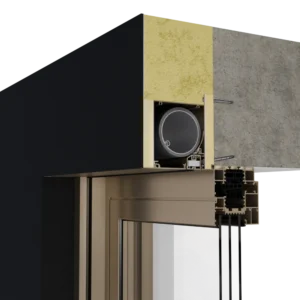

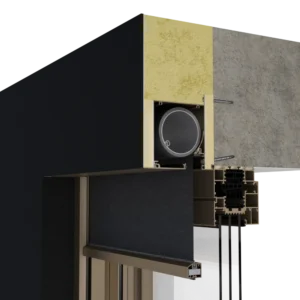

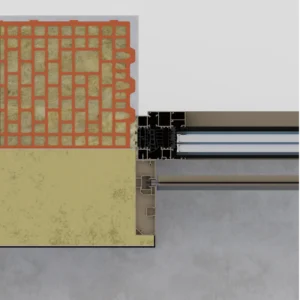

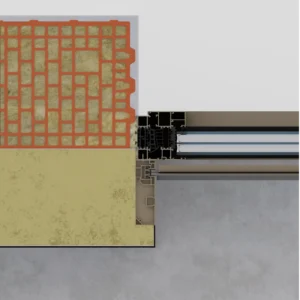

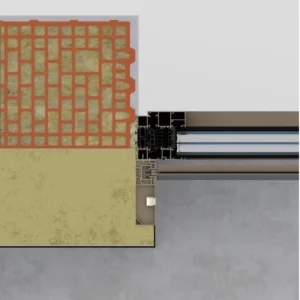

UNTERPUTZ SYSTEME

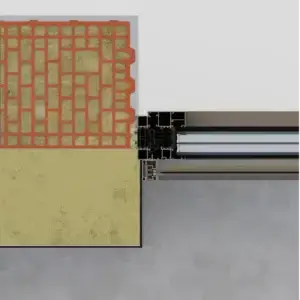

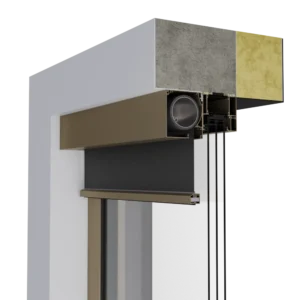

WS 110 PO1

WS 110 PO1

WS 110 PO1

WS 110 PO1 UNTERPUTZSYSTEM WS 110 PO1

Kastengröße: 110 x 120 mm

Maximale Systemabmessungen: 5000 x 3000 mm \[15,00 m²] oder 4000 x 4000 mm \[16,00 m²]

Wellendurchmesser: ∅ 63 mm, ∅ 78 mm

Dämmung: Rückseite des Kastens mit 20 mm starker PIR-Platte gedämmt

Unterleiste: LD-1 (verschwindet vollständig im Kasten), LD-2 (verschwindet nicht vollständig im Kasten)

HINWEIS: Bei Rollläden mit einer Breite bis 1200 mm wird die beschwerende Unterleiste LD-2 verwendet, die nicht vollständig im Kasten verschwindet.

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGEN

EINZELFÜHRUNG ZIP: AZ1

DOPPELFÜHRUNGSSCHIENE ZIP: A2

EINZELFÜHRUNG ZIP: P1

DOPPELFÜHRUNGSSCHIENE ZIP: P2

STAHLSEIL

FREIHÄNGENDER ROLLLADEN

UNTERLEISTEN

UNTERLEISTE LD-1

* UNTERLEISTE LD-2

* Die Unterleiste LD-2 wird bei Rollläden mit einer Breite bis 1200 mm eingesetzt und verschwindet nicht vollständig im Kasten.

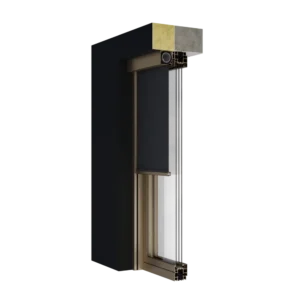

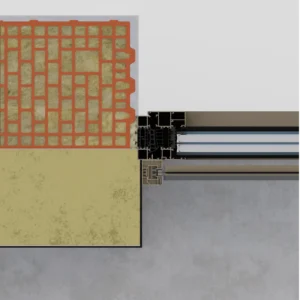

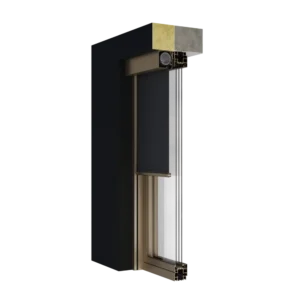

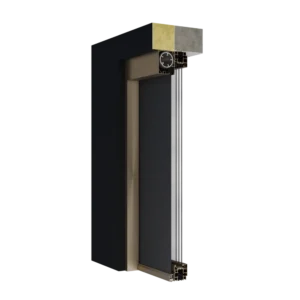

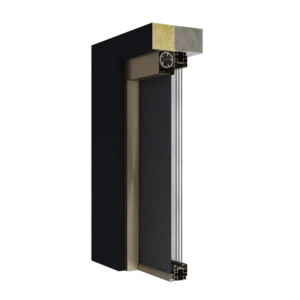

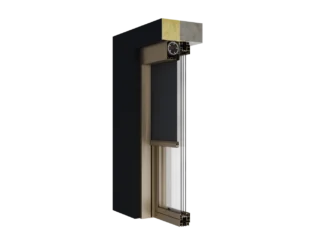

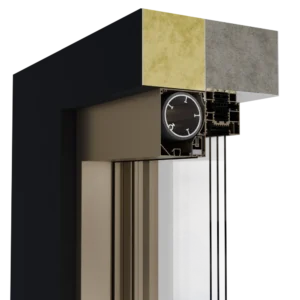

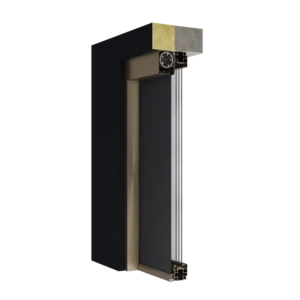

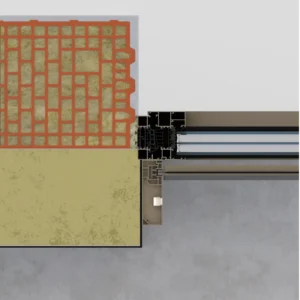

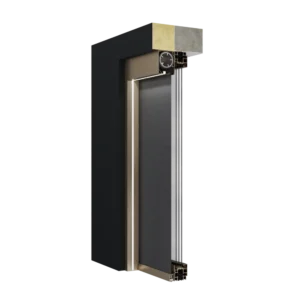

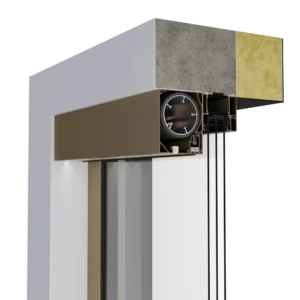

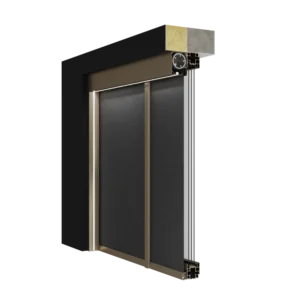

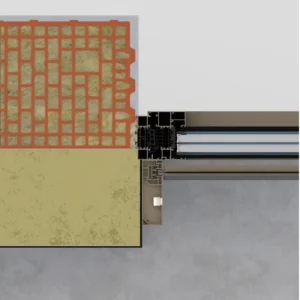

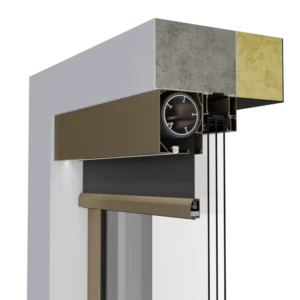

WS 130 PO2

WS 130 PO2

WS 130 PO2

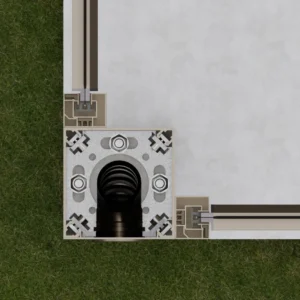

WS 130 PO2 UNTERPUTZSYSTEM WS 130 PO2

Kastengröße: 130 x 160 mm

Maximale Systemabmessungen: 7000 x 3400 mm \[23,88 m²] oder 5400 x 6000 mm \[32,40 m²]

Wellendurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Dämmung: Rückseite des Kastens mit 20 mm starker PIR-Platte gedämmt

Unterleiste: LD-2 (verschwindet vollständig im Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGSSCHIENEN

EINFACHFÜHRUNGSSCHIENE ZIP: AZ1

DOPPELFÜHRUNGSSCHIENE ZIP: A2

EINFACHFÜHRUNGSSCHIENE ZIP: P1

DOPPELFÜHRUNGSSCHIENE ZIP: P2

EINFACHFÜHRUNGSSCHIENE ZIP: P3

EINFACHFÜHRUNGSSCHIENE ZIP: Z2

STAHLSEIL

FREIHÄNGENDER ROLLLADEN

UNTERLEISTEN

UNTERLEISTE LD-2

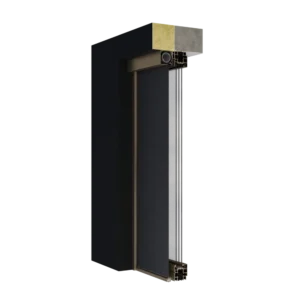

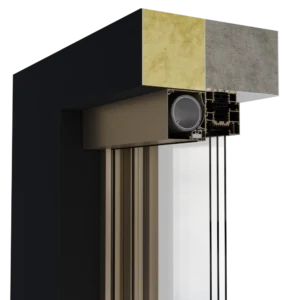

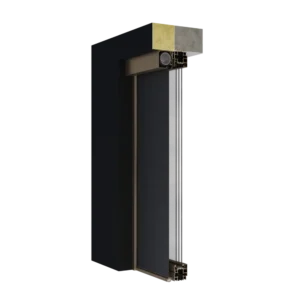

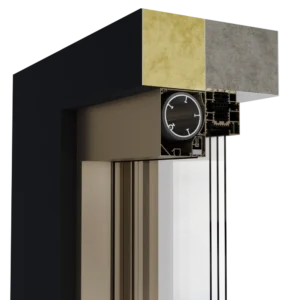

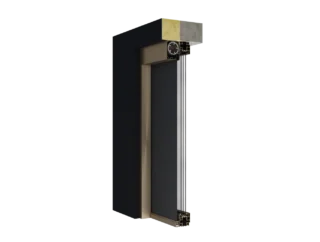

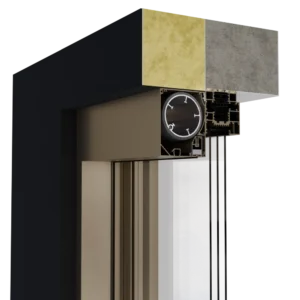

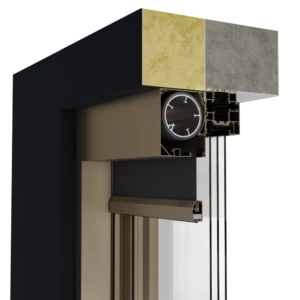

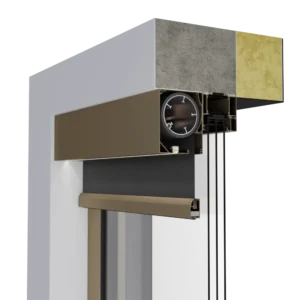

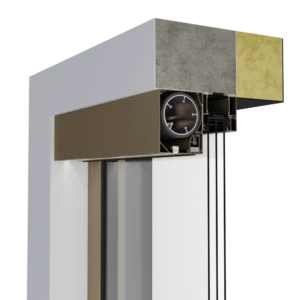

WS 130 PO3 LED

WS 130 PO3 LED

WS 130 PO3 LED

WS 130 PO3 LED UNTERPUTZSYSTEM WS 130 PO3 LED

Kastengröße: 130 x 160 mm

LED-Beleuchtung: integrierte lineare LED-Beleuchtung im Kasten

Maximale Systemabmessungen: 7000 x 3400 mm \[23,88 m²] oder 5400 x 6000 mm \[32,40 m²]

Wellendurchmesser: ∅ 78 mm, ∅ 85 mm, ∅ 100 mm ALU

Dämmung: Rückseite des Kastens mit 20 mm starker PIR-Platte gedämmt

Unterleiste: LD-2 (verschwindet vollständig im Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGSSCHIENEN

EINFACHFÜHRUNGSSCHIENE ZIP: AZ1

DOPPELFÜHRUNGSSCHIENE ZIP: A2

EINFACHFÜHRUNGSSCHIENE ZIP: P1

PROWADNICA PODWÓJNA ZIP: P2

EINFACHFÜHRUNGSSCHIENE ZIP: P3

EINFACHFÜHRUNGSSCHIENE ZIP: P4

EINFACHFÜHRUNGSSCHIENE ZIP: Z2

EINFACHFÜHRUNGSSCHIENE ZIP: Z5

STAHLSEIL

FREIHÄNGENDER ROLLLADEN

UNTERLEISTEN

UNTERLEISTE LD-2

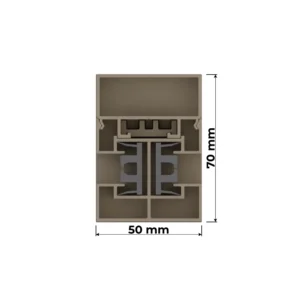

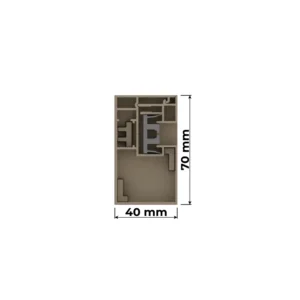

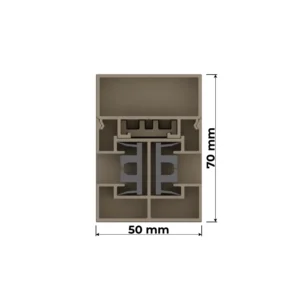

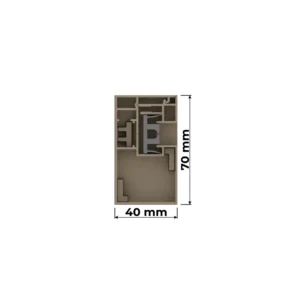

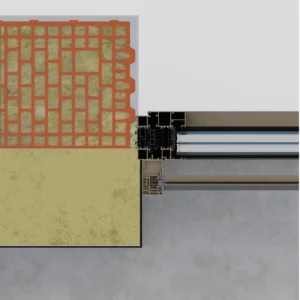

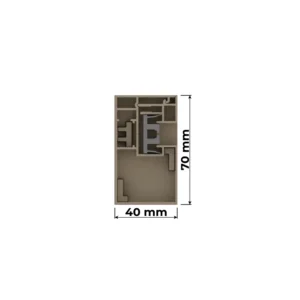

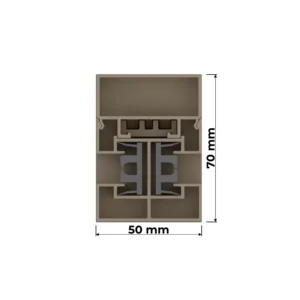

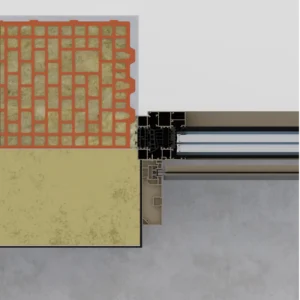

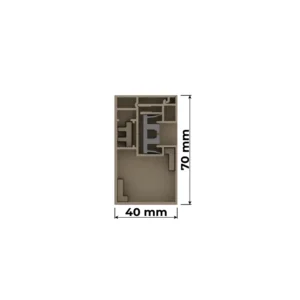

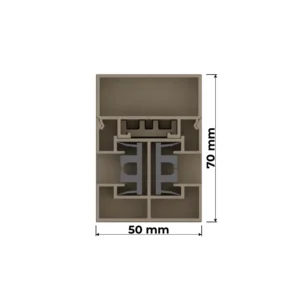

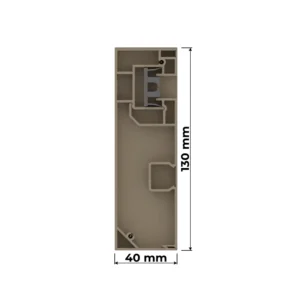

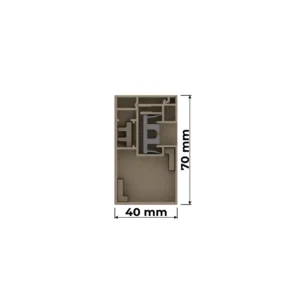

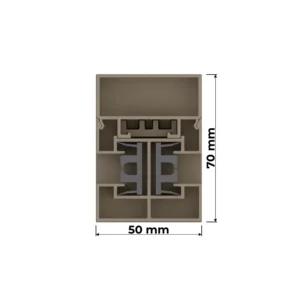

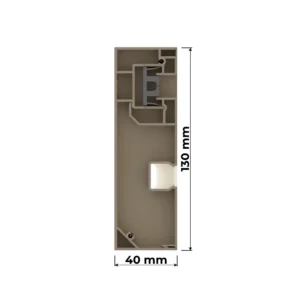

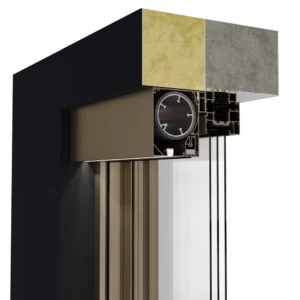

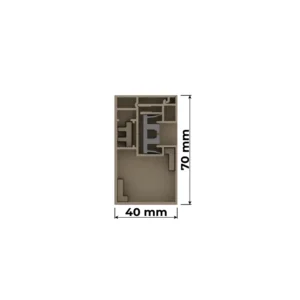

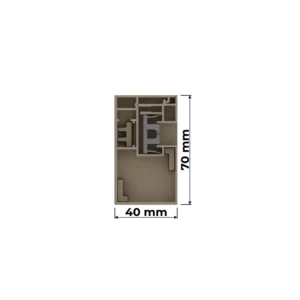

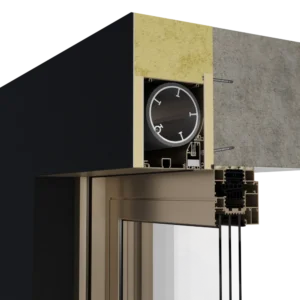

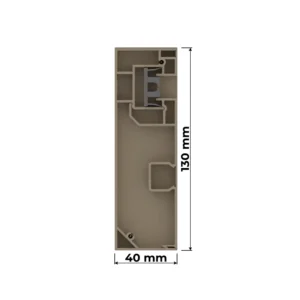

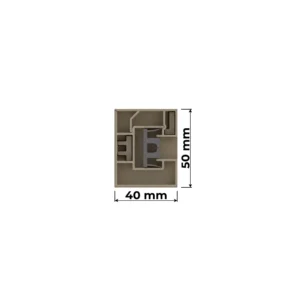

CLICK-SYSTEM DER UNTERPUTZFÜHRUNGSSCHIENEN

Das CLICK-System ist eine moderne Lösung für Unterputz-Führungsschienen in den Abmessungen 40 x 70 mm und 40 x 130 mm, die eine schnelle, werkzeuglose Montage sowie eine stabile Verbindung der Elemente ermöglicht. Dank des innovativen Schnappmechanismus erfolgt die Montage der Führungsschiene intuitiv, präzise und ohne den Einsatz von Schrauben, was den Installationsprozess erheblich beschleunigt.

Diese Lösung garantiert eine stabile Positionierung der Führungsschiene und eliminiert das Risiko von Spiel oder Unebenheiten. Zudem sorgt sie für ein ästhetisches Finish, das sich perfekt in den Unterputzkasten einfügt.

PROFILIERTE MONTAGEBEREICHE

Der Unterputzkasten wurde für eine stabile und präzise Montage entwickelt und verfügt daher im Inneren über eine profilierte Montagewand, die zur Befestigung mit Schrauben vorgesehen ist.

Dank dieser Lösung ist ein direkter Zugang zur Montagestelle möglich und der Kasten kann im unteren Bereich sicher und stabil verschraubt werden. Dies gewährleistet ein festes Andrücken des Kastens an den Fensterrahmen, eliminiert das Risiko von Spiel und sichert die Langlebigkeit der gesamten Konstruktion.

Profilierte Montagebereiche stellen eine Erleichterung für die Installateure dar und garantieren eine stabile Positionierung des Rollladensystems, was dessen Zuverlässigkeit nachhaltig erhöht.

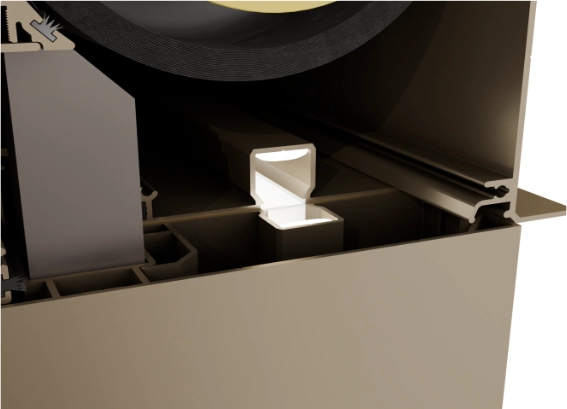

LED-BELEUCHTUNG IM KASTEN

Der Unterputzkasten 130 mm x 160 mm wurde mit der Option zur Integration einer COB-LED-Beleuchtung in der Revisionsklappe entwickelt, wodurch eine subtile und effektvolle Ausleuchtung des Bereichs unter dem Rollladen ermöglicht wird.

Die COB-LED-Beleuchtung in der Revisionsklappe ist nicht nur ein moderner visueller Akzent, sondern auch eine praktische Lösung, die als dekorative Fassadenbeleuchtung dienen kann und das elegante Erscheinungsbild des Gebäudes sowohl tagsüber als auch bei Dunkelheit unterstreicht.

OBERES PROFIL MIT STOFF VERSCHWEISST

Zastosowanie wyprofilowanego profilu montażowego zgrzewanego z górną krawędzią tkaniny to rozwiązanie, które eliminuje standardową kieszeń na wkład, upraszcza montaż i ułatwia serwis. Dzięki możliwości wpięcia i wypięcia tkaniny bez demontażu rury nawojowej, system ten zapewnia szybszą obsługę, dłuższą żywotność tkaniny oraz wyższą estetykę. Dodatkowo optymalizowana geometria profilu eliminuje problem odcisków na tkaninie, co wyróżnia to rozwiązanie na tle klasycznych systemów rolet screen ZIP.

GRÖSSTE ABMESSUNGEN AM MARKT

Das Unterputzsystem zeichnet sich durch die größten am Markt verfügbaren Abmessungen aus, was seinen Einsatz in Projekten mit großformatigen Beschattungen ermöglicht. Dank der fortschrittlichen Konstruktion und der Verwendung robuster Komponenten gewährleistet dieses System Stabilität und einen reibungslosen Betrieb auch bei sehr großen Dimensionen.

Die Möglichkeit, Beschattungen in großen Spannweiten zu realisieren, macht das Unterputzsystem sowohl im Wohnungsbau als auch im gewerblichen Bereich ideal einsetzbar. Durch präzise konstruierte Elemente behalten selbst die größten Anlagen ihr ästhetisches Erscheinungsbild, ihre Zuverlässigkeit und ihre einfache Bedienung.

Es handelt sich um eine innovative Lösung, die neue Maßstäbe bei Sonnenschutzsystemen setzt, den größten Dimensionierungsbereich am Markt bietet und sich vollständig in die moderne Architektur integriert.

CLICK-SYSTEM DER ZIP-FÜHRUNGSSCHIENEN

Das CLICK-System in den ZIP-Führungsschienen ist eine innovative Lösung, die eine schraubenlose Verbindung des Führungsschienenprofils mit dem Abschlussprofil ermöglicht. Dank des Schnappmechanismus erfolgt die Montage schnell, präzise und ohne Bohren oder Schrauben, wodurch sichtbare Befestigungselemente entfallen und die Ästhetik des gesamten Systems deutlich verbessert wird. Diese Lösung erleichtert zudem den Service und die Demontage, ohne das Risiko einer Beschädigung der Fassade oder der Führungsschiene.

Die Lösung besteht aus zwei Materialien mit unterschiedlicher Dichte – das eine sorgt für eine stabile Position in der Führungsschiene, während das andere, flexiblere, den Stoff im Rollladen gleichmäßig spannt und so Wellenbildung und Falten verhindert.

LED-BELEUCHTUNG IN DEN ZIP-FÜHRUNGSSCHIENEN

Die LED-Beleuchtung in den großen ZIP-Führungsschienen wurde im Inneren des Profils in einem speziell entwickelten Revisionsraum integriert. Diese Lösung ermöglicht eine gleichmäßige Ausleuchtung der gesamten Stoffhöhe des Rollladens und sorgt für einen ästhetischen Lichteffekt in der Nische oder im Nutzungsbereich, z. B. unter einer Pergola. Die Beleuchtung ist hinter einer Blende verborgen, was ein elegantes Erscheinungsbild ohne sichtbare Lichtquellen gewährleistet.

DOPPELFÜHRUNGSSCHIENEN

Die Doppelführungsschiene mit Distanzstück ist eine speziell entwickelte ZIP-Führungsschiene für Unterputzsysteme, die die Montage von zwei oder mehr Rollläden in einer einzigen Öffnung ermöglicht, z. B. bei HS-Fenstern mit Mittelpfosten.

Dank der optimalen Abmessungen passt sich die Führungsschiene an die meisten Pfosten in Fenstersystemen an, was ein ästhetisches Erscheinungsbild und eine stimmige Integration in die Fassade gewährleistet. Das eingesetzte Distanzstück sorgt für eine präzise Anpassung an das Unterputzsystem.

Es handelt sich um eine praktische und elegante Lösung, die eine funktionale Aufteilung der Sonnenschutzanlagen ermöglicht, dabei jedoch ein minimalistisches Design und eine hohe Verarbeitungsqualität beibehält.

MONTAGEÖFFNUNGEN

Die Montageöffnungen für die Verkabelung wurden so entwickelt, dass eine schnelle und komfortable Führung der Stromkabel für Antrieb oder Beleuchtung möglich ist, wodurch zusätzlicher Bearbeitungsaufwand während der Installation minimiert wird. Ihre optimale Anordnung gewährleistet eine sichere und ästhetische Kabelführung, was nach Abschluss der Montage zu einem ordentlichen Erscheinungsbild des Systems beiträgt.

Die Öffnungen sind an mehreren Stellen im aus Aluminium gegossenen Seitenteil des Rollladens vorgesehen, was eine flexible Wahl der Kabelführung für den Antrieb ermöglicht und die Installation an die individuellen Montagebedingungen anpasst.

UNIVERSELLE ANTRIEBSBEFESTIGUNGEN

Die Antriebsbefestigung ermöglicht dank ihrer durchdachten Konstruktion eine schnelle und problemlose Montage sowie Demontage des Antriebs – unabhängig von den spezifischen Installationsbedingungen.

Das Befestigungssystem zeichnet sich durch eine solide und stabile Lagerung des Antriebs aus, was einen zuverlässigen Betrieb des Rollladens gewährleistet. Zudem erlaubt die Befestigung eine axiale Drehung des Antriebs in 60-Grad-Schritten, was sowohl für die freie Kabelführung des Rollladenantriebs als auch für den bequemen Zugang zu den mechanischen Endlagen des Antriebs von Bedeutung ist.

4 WICKELWELLENDURCHMESSER MIT DEKORPROFIL

Im System werden vier Wickelwellendurchmesser eingesetzt:

Ø 63 mm, Ø 78 mm, Ø 85 mm – Stahlwickelwellen, die hohe Festigkeit und Verformungsbeständigkeit bieten und ideal für Standard- und mittelgroße Rollläden geeignet sind.

Ø 100 mm – systemische Aluminiumwelle aus der Legierung 6063 T6, vorgesehen für großformatige Rollläden.

Jede dieser Wellen ist mit speziellen Stoffprofilen kompatibel, die eine Montage oder einen Austausch ermöglichen, ohne dass die Wickelwelle aus dem Rollladen demontiert werden muss. Dadurch werden Wartung und Anpassung des Rollladens an neue Nutzungsbedingungen schnell und komfortabel, ohne in die gesamte Konstruktion eingreifen zu müssen.

STAHLTEILUNGEN DER ANLAGEN

Die Stahlteilungen der Anlagen sind robuste und präzise konstruierte Elemente, die bei Doppelführungsschienen mit Distanzstück eingesetzt werden. Ihre Hauptfunktion besteht darin, zwei unabhängige Rollläden in einem System stabil zu positionieren und voneinander zu trennen, z. B. bei Unterputzlösungen für HS-Fenster mit Mittelpfosten.

Gefertigt aus hochfestem Stahl, gewährleisten diese Teilungen eine solide Befestigung sowohl für die Rollladenantriebe als auch für die Lager der Wickelwellen. Durch diese Lösung bleibt das gesamte System stabil, präzise in der Funktion und langlebig – auch bei großformatigen Beschattungen.

Es handelt sich um eine zuverlässige Lösung, die die Funktionalität von ZIP-Systemen erhöht und eine sichere Montage sowie eine lange Lebensdauer der Konstruktion garantiert.

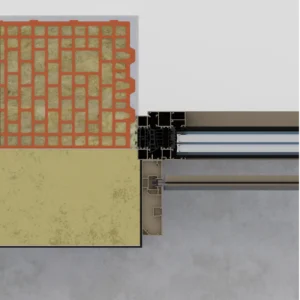

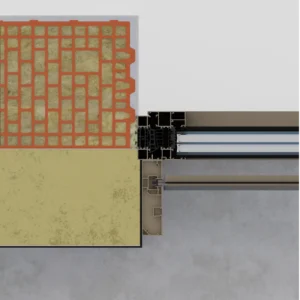

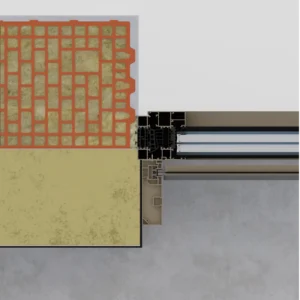

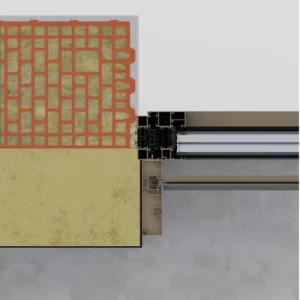

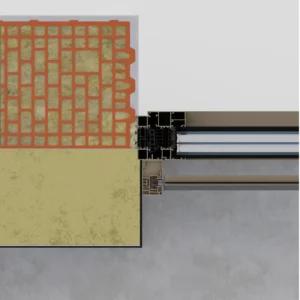

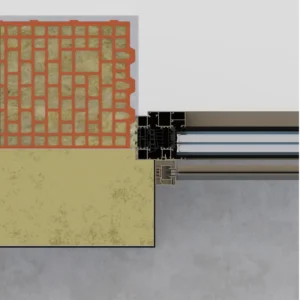

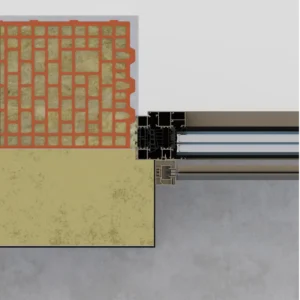

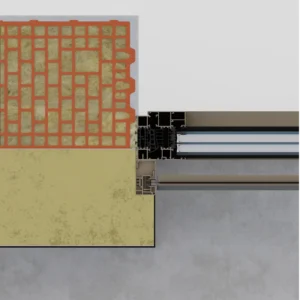

VORDERE PUTZTRÄGERLEISTE

Der integrierte Putzträger ist zusammen mit dem Systemkasten stranggepresst. Im Gegensatz zu den auf dem Markt erhältlichen Standardlösungen entfällt dadurch die Notwendigkeit einer separaten Montage, was die Installation beschleunigt und die Ästhetik des Finishs verbessert. Der Träger mit einer Tiefe von 20 mm bietet einen stabilen und dauerhaften Untergrund für die Putz- und Dämmschicht.

MONTAGEWINKEL

Der integrierte obere Montagewinkel wird zusammen mit dem Systemkasten stranggepresst. Dadurch entfällt die Notwendigkeit zusätzlicher Befestigungen oder separater Winkel, was die Montage erheblich erleichtert und beschleunigt. Der Winkel verfügt über eine Bohrmarkierung, die eine präzise Installation gewährleistet. Sein Einsatz eliminiert das Risiko einer Beschädigung des Stoffes oder der Rollladenelemente während der Montage und garantiert eine stabile und sichere Befestigung des Kastens an der Wand.

INTEGRIERTER HINTERER MONTAGEWINKEL

Der integrierte hintere Kastenwinkel wird zusammen mit dem Kasten stranggepresst und erfordert dadurch keine zusätzliche Montage oder Verschraubung, was das Risiko einer Beschädigung des Kastens minimiert und die Installation erheblich beschleunigt.

Der Winkel mit einer Tiefe von 20 mm ermöglicht die Dämmung des Kastens von der Rückseite, wodurch Wärmebrücken eliminiert und die Energieeffizienz des Systems verbessert werden. Zusätzlich ist er mit einer innovativen Lösung ausgestattet – einer Gummidichtung, die ein festes Andrücken des Kastens an den Fensterrahmen ermöglicht. Dies gewährleistet eine dichte Montage, eliminiert potenzielle Spalten an den Fensterrahmen und erhöht die Qualität der Ausführung.

INTEGRIERTER HINTERER WINKELTRÄGER

Der Kasten des Unterputzsystems WIN SCREEN ist mit Markierungen ausgestattet, die das Bohren erleichtern und eine schnelle sowie präzise Herstellung der Öffnungen für die Montage oder die Durchführung der Stromkabel von Rohrmotoren bei Sonderausführungen ermöglichen.

GUSSSEITENTEILE AUS ALUMINIUM

Die gegossenen Aluminium-Seitenteile wurden präzise so entwickelt, dass sie in verschiedenen Systemvarianten eingesetzt werden können und dabei Stabilität, Langlebigkeit sowie volle Funktionalität gewährleisten. Die Seitenteile verfügen über systemische Befestigungen für die Stromkabel des Antriebs sowie zusätzliche Markierungen, die das präzise Anbringen der Öffnungen für die Kabelausführung des Rollladenantriebs erleichtern. Zudem sind die Seitenteile mit dem CLICK-System zum Verriegeln der Revisionsklappen ausgestattet, ohne dass ein Bohren erforderlich ist.

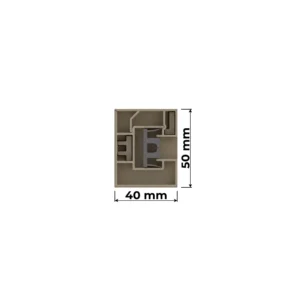

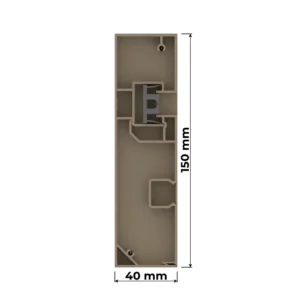

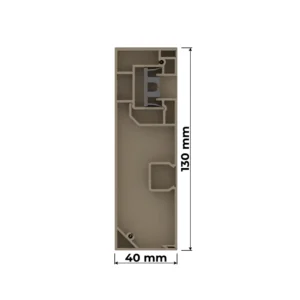

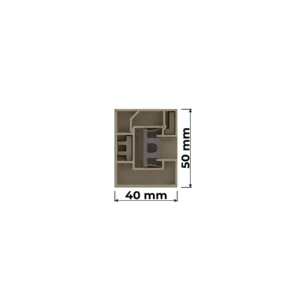

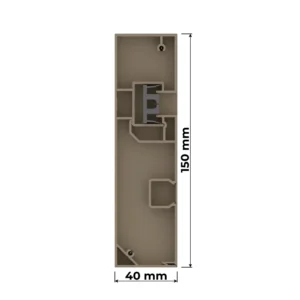

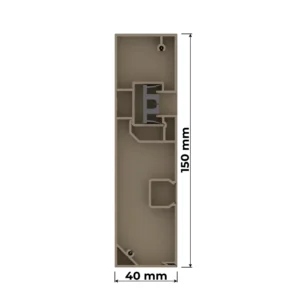

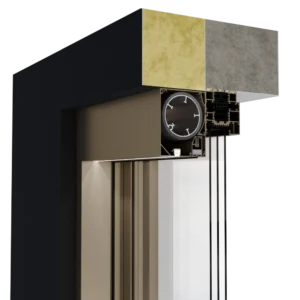

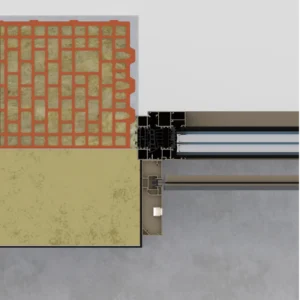

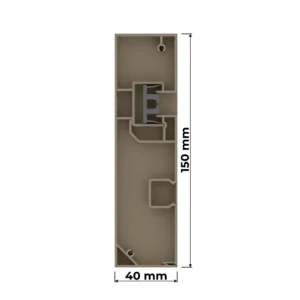

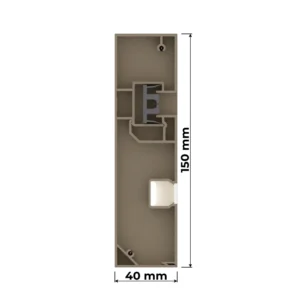

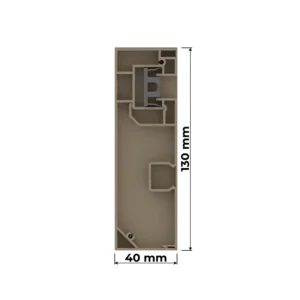

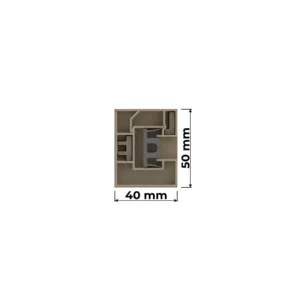

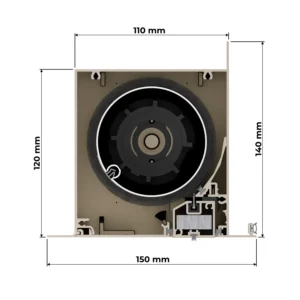

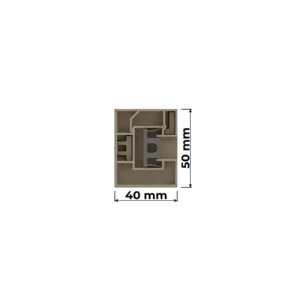

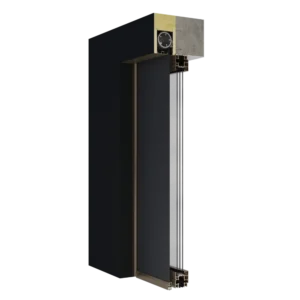

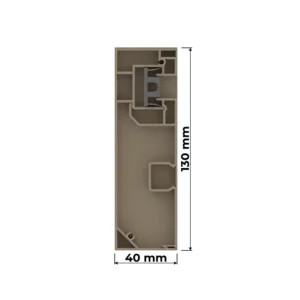

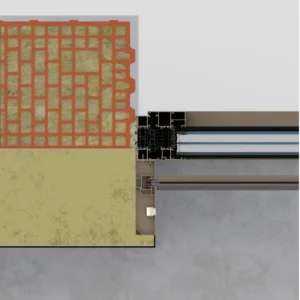

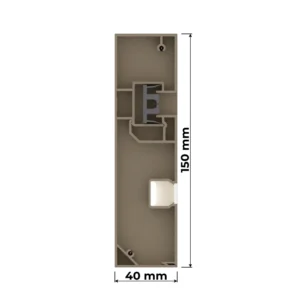

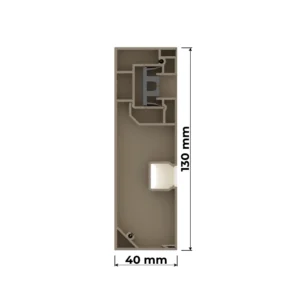

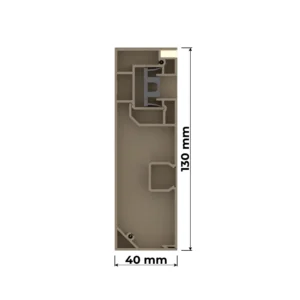

BREITE UNTERPUTZFÜHRUNGSSCHIENE FÜR VERKLEIDUNG

Die Unterputz-Führungsschiene mit den Abmessungen 40 mm x 150 mm und integriertem 20-mm-Distanzstück ist die ideale Lösung für Außenanwendungen. In Kombination mit dem Unterputzkasten mit hinterem Putzträger und Dichtung gewährleistet sie ein ästhetisches und langlebiges Endergebnis, das sich perfekt in die Fassade des Gebäudes einfügt.

Ein zusätzlicher Vorteil ist die Schnappverbindung der Führungsschiene mit dem Abschlussprofil, die den Einsatz von Schrauben überflüssig macht und so eine schnelle und einfache Montage sowie ein minimalistisches Erscheinungsbild ermöglicht.

Der Innenraum der Führungsschiene erlaubt das Verbergen von Verkabelungen, Netzteilen oder Steuerzentralen für die Beleuchtung.

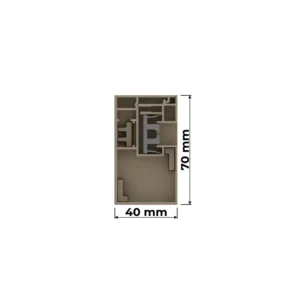

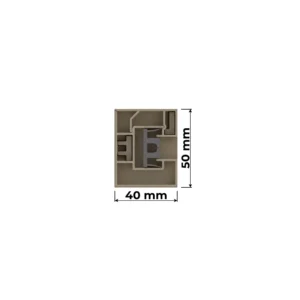

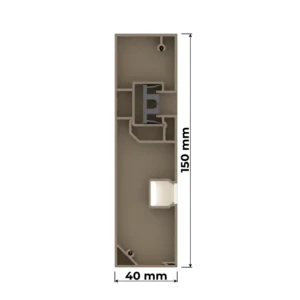

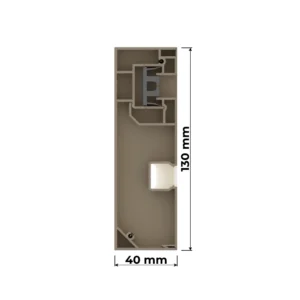

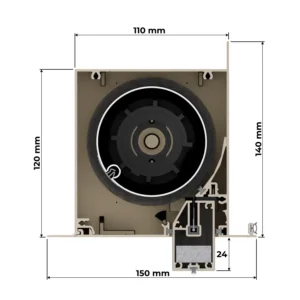

UNTERPUTZFÜHRUNGSSCHIENE FÜR VERKLEIDUNG

Die Unterputz-Führungsschiene mit den Abmessungen 40 mm x 70 mm ist eine funktionale Lösung, die Langlebigkeit und ein ästhetisches Fassadenfinish gewährleistet. Dank des integrierten 20-mm-Distanzstücks fügt sie sich perfekt in den Unterputzkasten mit hinterem Putzträger und Gummidichtung ein und bildet so eine stimmige Verkleidung.

Ihr Vorteil ist die Schnappverbindung mit dem Abschlussprofil der Führungsschiene, die den Einsatz von Schrauben überflüssig macht, die Montage erleichtert und die modernen Systemlösungen unterstreicht.

UNTERLEISTEN

Das Screen-Rollladensystem wurde mit unteren Abschlussleisten ausgestattet, die den Stoff in mehreren Größen beschweren und so unterschiedlichen ästhetischen und technischen Anforderungen gerecht werden. Jede von ihnen gewährleistet die Stabilität des Stoffes, dessen gleichmäßige Spannung sowie einen reibungslosen Lauf des Rollladens, während die größere Variante der Leiste die Schweißnaht des Stoffes verdeckt und so für ein noch ästhetischeres Finish sorgt.

ALUMINIUM-WICKELWELLE 100 mm

Die systemische Aluminium-Wickelwelle mit einem Durchmesser von 100 mm ist ein zentrales Element für großformatige Anlagen und gewährleistet hohe Festigkeit sowie einen stabilen Betrieb des Systems. Sie wird aus der Aluminiumlegierung 6063 T6 gefertigt und zeichnet sich durch eine geringe Durchbiegung aus. Damit stellt sie ein wesentliches Bauteil für großdimensionierte Systeme dar, das sich durch vorteilhafte Eigenschaften, insbesondere die niedrige Durchbiegung, auszeichnet.

Dank der präzisen Verarbeitung ermöglicht die Welle ein gleichmäßiges und flüssiges Aufwickeln des Stoffes, während eine spezielle Abstufung im Durchmesser Verformungen reduziert und so ein ästhetisches Erscheinungsbild sowie die Langlebigkeit des Materials sichert. Darüber hinaus verwendet das System ein Stoffeinsteckprofil, das den Austausch des Stoffes ermöglicht, ohne die Welle aus dem Rollladen ausbauen zu müssen, was die Wartung und Instandhaltung erheblich erleichtert.

ZIP-EINSATZ

Der ZIP-Einsatz ist eine moderne Lösung im System, die maximale Stabilität und ein gleichmäßiges Führen des Stoffes gewährleistet. Durch die Anwendung der ZIP-Reißverschlusstechnologie wird das Material gleichmäßig gespannt und über die gesamte Höhe in den Führungsschienen gehalten, was sowohl Windbeständigkeit als auch das Fehlen von Spiel an den Kanten garantiert.

Der Einsatz besteht aus zwei Materialien mit unterschiedlicher Dichte – das eine sorgt für eine stabile Position in der Führungsschiene, während das andere, flexiblere, den Stoff im Rollladen gleichmäßig spannt und so Wellenbildung und Falten verhindert.

VERDECKTE UNTERLEISTE

Im Adaptivsystem wurde eine verdeckte Unterleiste eingesetzt, die für ein ästhetisches und stimmiges Finish des Rollladens sorgt. Die Unterleisten sind in mehreren Größen erhältlich, je nach Kastengröße oder Anwendungsbereich. Dank der durchdachten Konstruktion verschwindet die Leiste beim Hochfahren vollständig im Rollladenkasten, wodurch sich das System minimalistisch und elegant präsentiert – ohne sichtbare untere Elemente.

Diese Lösung gewährleistet ein einheitliches Erscheinungsbild der gesamten Anlage und macht das System zur idealen Wahl für moderne Fassaden und Gebäudefronten, bei denen Ästhetik und hohe Verarbeitungsqualität im Vordergrund stehen.

GLEITPROFIL

Das Gleitprofil für den Stoff mit integrierter Bürstendichtung ist ein Element im Inneren des Kastens, das für die Stabilisierung und die korrekte Führung des Stoffes verantwortlich ist. Seine Aufgabe besteht darin, das Material in der richtigen Position zu halten und so einen gleichmäßigen und störungsfreien Lauf des Rollladens zu gewährleisten.

Durch den Einsatz der Bürstendichtung minimiert das Profil die Reibung des Stoffes, schützt diesen vor Beschädigungen und verlängert seine Lebensdauer. Zudem wirkt die Dichtung dämpfend, reduziert Geräusche und verbessert die Dichtheit des gesamten Systems. Diese Lösung garantiert einen präzisen und leisen Betrieb und steigert somit den Komfort sowie die Zuverlässigkeit des Sonnenschutzsystems.

ABDECKKAPPEN DER UNTERLEISTEN

Die Abdeckkappen der Unterleiste wurden mit präzise geformten Nuten entwickelt, die die Linie der Bürstendichtungsnut in der Leiste selbst fortsetzen. Dadurch kann die Dichtung über die gesamte Breite des Rollladens – von Kappe zu Kappe – geführt werden, was die Entstehung von Spalten an den Kanten der Unterleiste verhindert. Diese Lösung sorgt für eine bessere Abdichtung des Rollladens in geschlossener Position und reduziert das Eindringen von Licht, Insekten und Verschmutzungen.

INTELLIGENTE STEUERUNG

Dank der Verwendung einer intelligenten Steuerzentrale besteht die Möglichkeit, die Pergola sowie das zusätzliche Zubehör per Smartphone oder Tablet von jedem Ort der Welt aus zu bedienen.

PREMIUM-MATERIALIEN

Innovative Konstruktion mit Dacheindeckung aus stranggepresstem Aluminium und Edelstahl. Die Profile sind aus hochwertigem Aluminium stranggepresst, mit dicken und robusten Wandungen, verstärkt durch Kammern und Rippen. Die in der WIN CLIMATIC-Konstruktion verwendeten Stahlelemente bestehen aus Edelstahl höchster Qualität mit starkem Querschnitt.

REICHE FARBPALETTE DER KONSTRUKTION IM STANDARD

Wir bieten eine breite Farbpalette der Konstruktion bereits im Standard! Die Konstruktion wird pulverbeschichtet in sieben Farben aus der Standardpalette WIN CLIMATIC S500. Zusätzlich besteht die Möglichkeit einer Pulverbeschichtung in jeder beliebigen RAL-Farbe sowie in Holzdekorfarben.

KONFORMITÄT MIT CE-NORM

Unsere Produkte erfüllen die Anforderungen der Norm PN-EN 1090-1 bis PN-EN 1090-3, die vom Polnischen Komitee für Normung für Stahl- und Aluminiumkonstruktionen eingeführt wurde, was durch die CE-Kennzeichnung des Produkts bestätigt wird.

TIGER COATINGS

Dank des Einsatzes duroplastischer Pulverbeschichtungen erhalten wir nahezu unbegrenzte Möglichkeiten der Oberflächenveredelung. In unseren Produkten verwenden wir ausschließlich Beschichtungen von TIGER COATINGS, die Langlebigkeit und kompromisslose Verarbeitungsqualität gewährleisten.

DAUERHAFTE LACKBESCHICHTUNG

Alle von uns hergestellten Konstruktionen verfügen über ein internationales Zertifikat für die Qualität der Lackbeschichtungen. Mit dem QUALICOAT-Siegel ausgezeichnete Produkte zeichnen sich durch hervorragende Eigenschaften aus, die von akkreditierten Prüflaboren bestätigt wurden.

HOHE QUALITÄT DER PRODUKTAUSFÜHRUNG UND VERPACKUNG

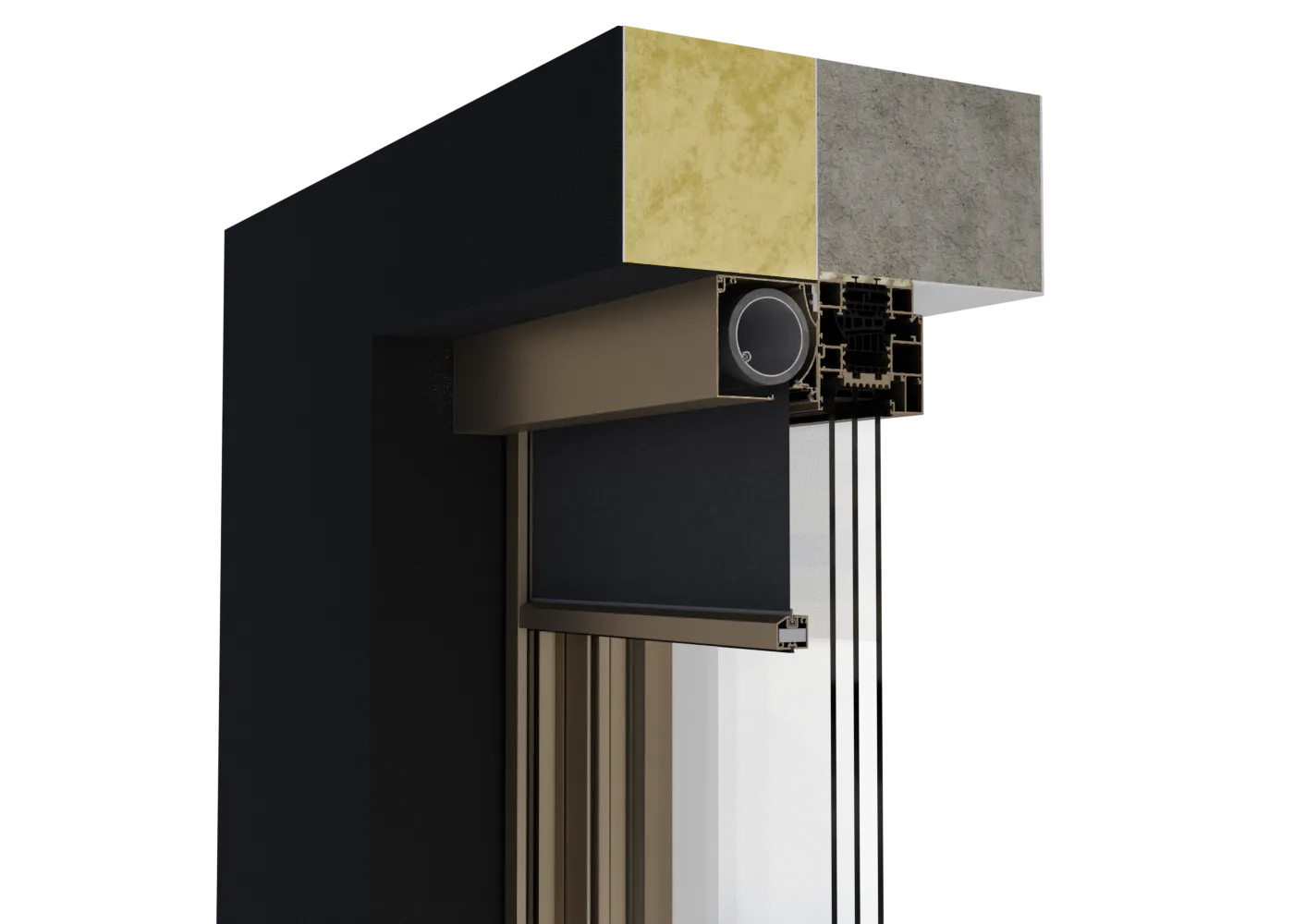

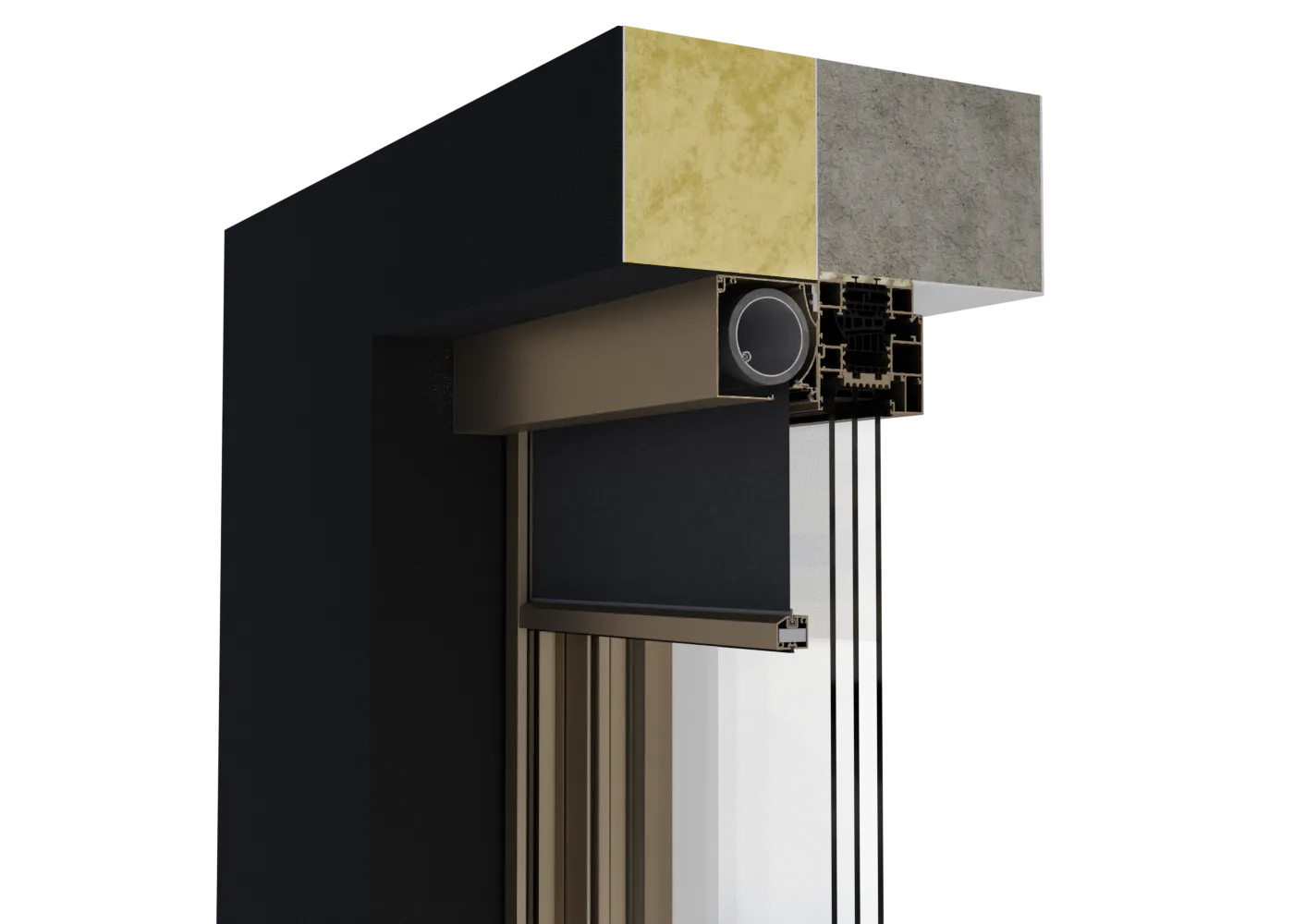

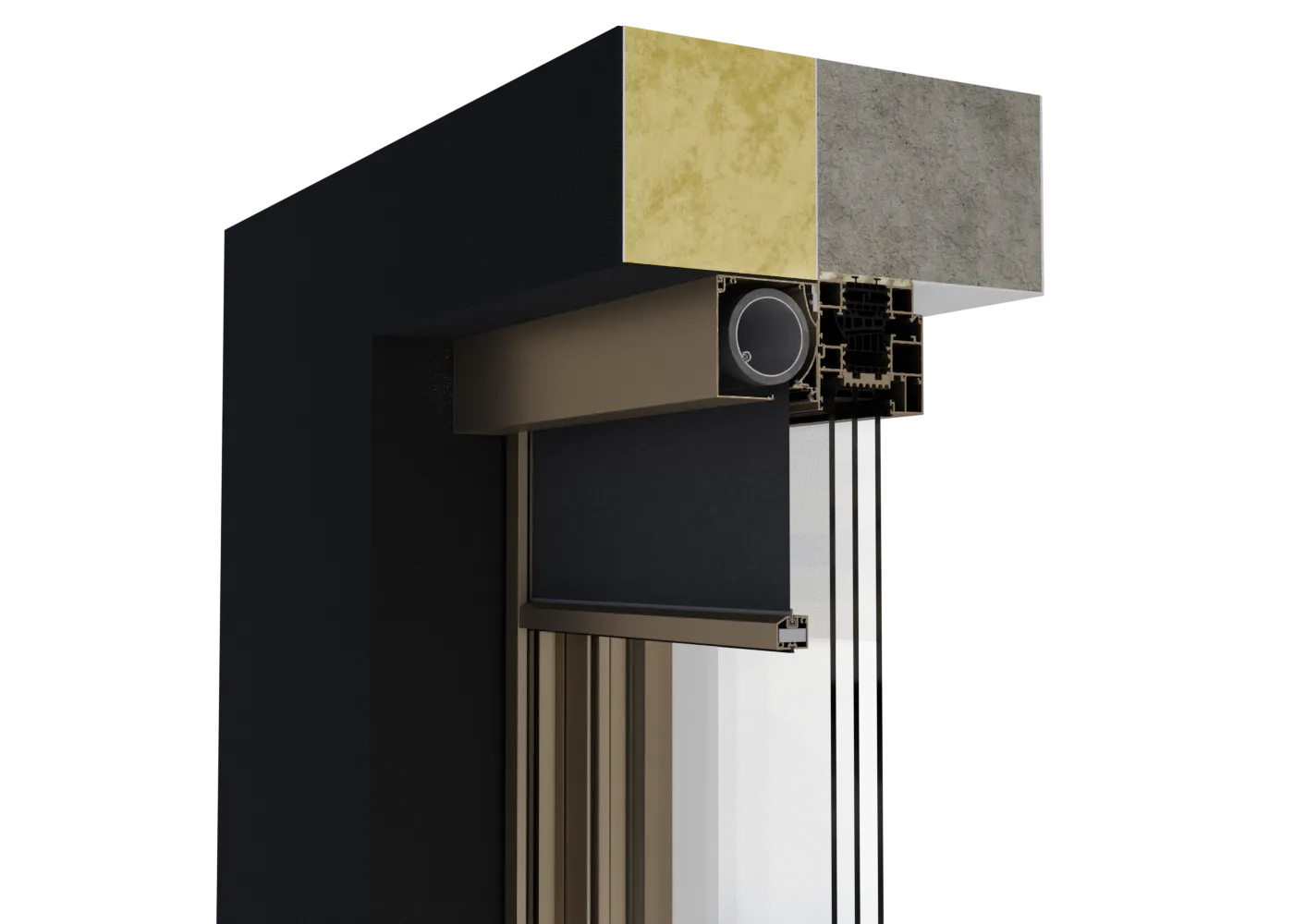

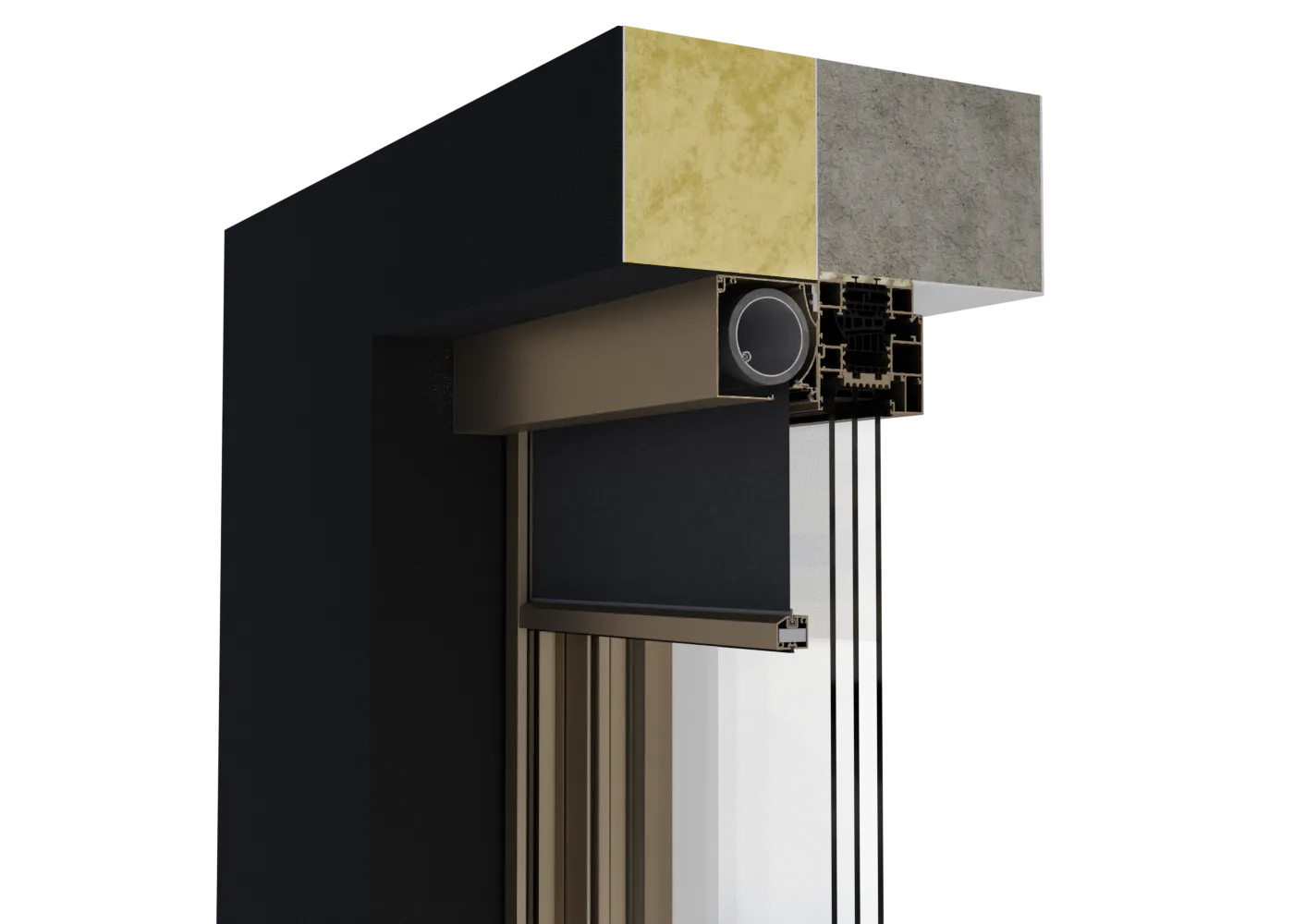

Ein spezialisiertes Team sowie ein hochmoderner Maschinenpark ermöglichen es uns, höchste Produktionsqualität zu erreichen. Jedes Produkt wird vor dem Versand von der Qualitätskontrolle sorgfältig auf Übereinstimmung mit der Bestellung sowie auf die Verarbeitungsqualität geprüft. Großen Wert legen wir außerdem auf eine sorgfältige Verpackung und Sicherung der Ware für den Transport. Durch den Einsatz speziell angepasster Styroporformteile, Luftpolstermatten sowie stabiler, robuster Kartons können wir gewährleisten, dass die bestellte Ware in einwandfreiem Zustand bei Ihnen ankommt.

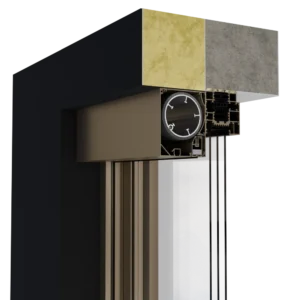

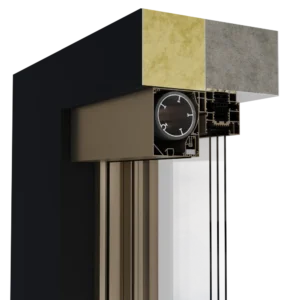

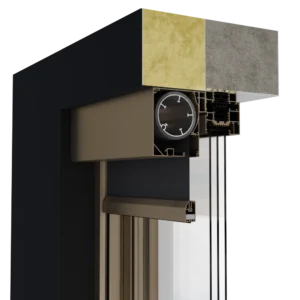

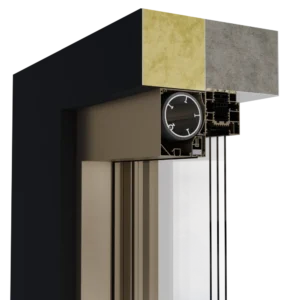

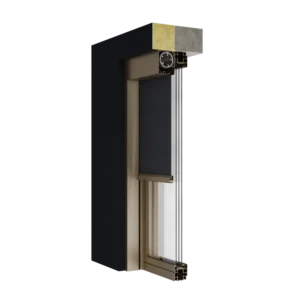

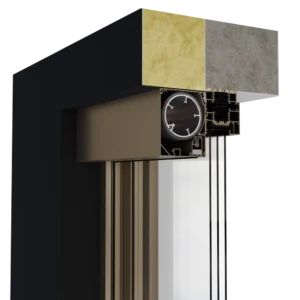

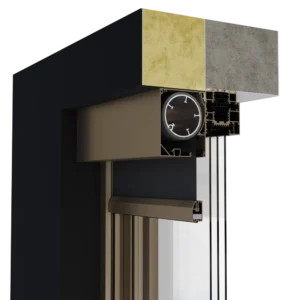

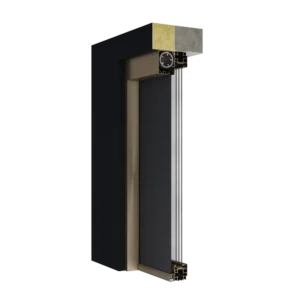

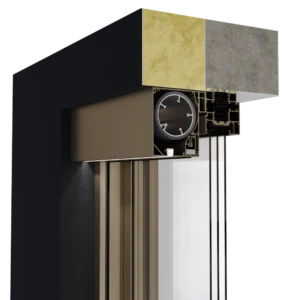

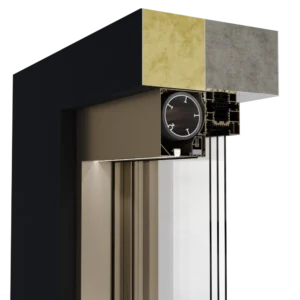

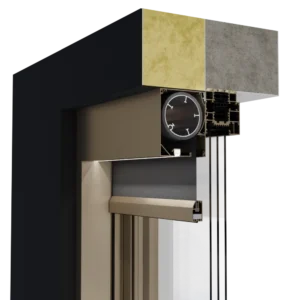

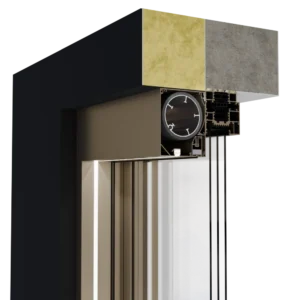

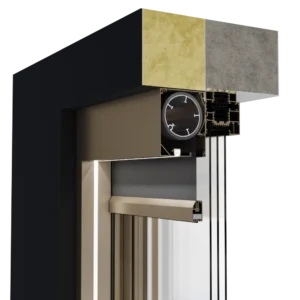

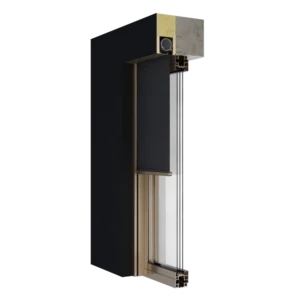

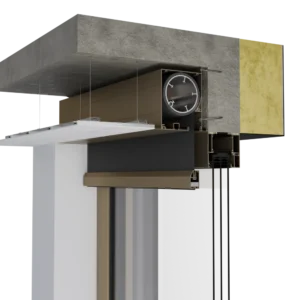

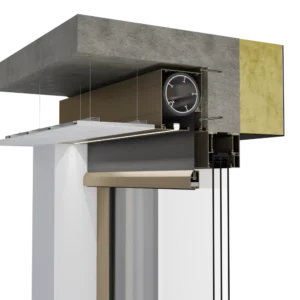

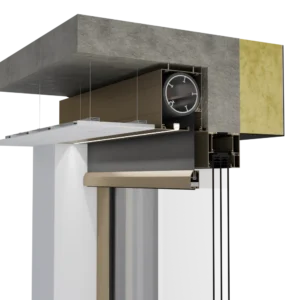

INTEGRIERTE SYSTEME

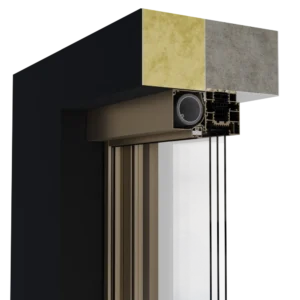

WS 130 Z1

WS 130 Z1

WS 130 Z1

WS 130 Z1 INTEGRIERTES SYSTEM WS 130 Z1

Kastengröße: 130 x 175 mm

Maximale Systemabmessungen: 7000 x 3400 mm \[23,80 m²]

Wellendurchmesser: ∅ 100 mm ALU

Unterleiste: LD-2 (verschwindet vollständig im Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGSSCHIENEN

EINFACHFÜHRUNGSSCHIENE ZIP: AZ1

EINFACHFÜHRUNGSSCHIENE ZIP: Z2

UNTERLEISTEN

UNTERLEISTE LD-2

MONTAGEHALTERUNGEN

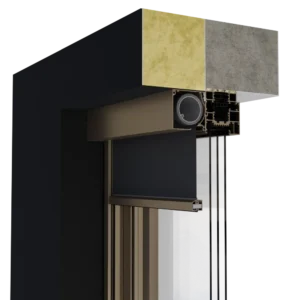

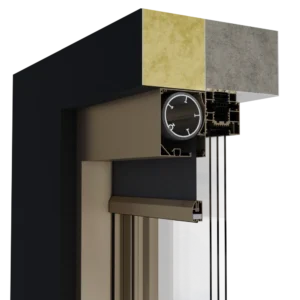

WS 130 Z2 LED

WS 130 Z2 LED

WS 130 Z2 LED

WS 130 Z2 LED INTEGRIERTES SYSTEM WS 130 Z2 LED

Kastengröße: 130 x 175 mm

Maximale Systemabmessungen: 7000 x 3400 mm \[23,80 m²]

Wellendurchmesser: ∅ 100 mm ALU

Unterleiste: LD-2 (verschwindet vollständig im Kasten)

BEISPIELHAFTE SYSTEMQUERSCHNITTE

FÜHRUNGSSCHIENEN

EINFACHFÜHRUNGSSCHIENE ZIP: AZ1

EINFACHFÜHRUNGSSCHIENE ZIP: Z2

EINFACHFÜHRUNGSSCHIENE ZIP: Z3

EINFACHFÜHRUNGSSCHIENE ZIP: Z4

EINFACHFÜHRUNGSSCHIENE ZIP: Z5

UNTERLEISTEN

UNTERLEISTE LD-2

* Die Unterleiste LD-2 wird bei Rollläden mit einer Breite bis 1200 mm eingesetzt und verschwindet nicht vollständig im Kasten

MONTAGEHALTERUNGEN

MONTAGEBÜGEL

Der Aufhänger bleibt unsichtbar und sorgt für ein ästhetisches Erscheinungsbild, während die Montage schnell und präzise erfolgt, ohne dass eine Schablone erforderlich ist, da ein integriertes Maß vorhanden ist, das nach dem Anschrauben an die Pergolarahmenkonstruktion entfernt wird.

INNERE STAHLSEITEN

Verdeckte innere Stahlseiten sind eine innovative Lösung, die ein minimalistisches Erscheinungsbild und hohe Widerstandsfähigkeit gewährleistet. Die Seiten sind vollständig im Kasten verborgen, ragen weder über dessen Kante noch über die Revisionsklappe hinaus, was eine vollständige Integration in die Konstruktion ermöglicht. Dank der selbsttragenden Bauweise ist der Rollladen stabil, benötigt keine zusätzlichen Halterungen und erlaubt die Realisierung großer Abmessungen. Im Gegensatz zu Standardlösungen, bei denen die Kastenseiten sichtbar sind, garantiert dieses System ein einheitliches, ästhetisches Erscheinungsbild der Pergola sowie eine erleichterte Montage.

MONTAGEKAMMERN

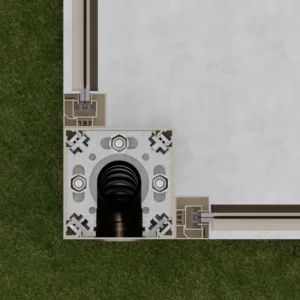

Montagekammern im unteren Teil des integrierten Rollladenkastens sind eine innovative Lösung, die die Konstruktion verstärkt und ihre Funktionalität erhöht. Durch die zwei Kammern erhält der Kasten zusätzliche Steifigkeit, ermöglicht die Montage von Führungsschienen für Schiebeglas, Fensterläden oder andere Verschattungen. Das System erlaubt die Integration des ZIP-Screen-Rollladens mit anderen Elementen in einer einzigen Nische, was bei Standardlösungen, bei denen die Montage separat erfolgt, nicht möglich ist. Darüber hinaus eliminieren die Kammern das Risiko von Undichtigkeiten und einer Beschädigung des Gewebes durch Schrauben und gewährleisten eine ästhetische und sichere Montage.

REVISIONSKLAPPE MIT LED-BELEUCHTUNG

Die Revisionsklappe des integrierten Rollladens kann mit einer innovativen Beleuchtung mittels LED-FLEX-Band ausgestattet werden, die eine effektvolle Hinterleuchtung des Screen-Gewebes ermöglicht. Das LED-Licht verbessert die Ästhetik, erhöht den visuellen Komfort und verstärkt den Sichtschutz, indem es die Transparenz des Gewebes bei schwacher Beleuchtung reduziert. Dank der integrierten Konstruktion erfolgt die Montage der LED ohne zusätzliche Profile, und die gleichmäßige Lichtstreuung sorgt für einen harmonischen Effekt. Eine Tasche schützt das Band vor Beschädigungen und äußeren Einflüssen und garantiert die Langlebigkeit und Zuverlässigkeit des Systems.

OBERES PROFIL MIT DEM GEWEBE VERSCHWEISST

Der Einsatz eines profilierten Montageprofils, das mit der oberen Stoffkante verschweißt ist, stellt eine Lösung dar, die die herkömmliche Tasche für Einlagen überflüssig macht, die Montage vereinfacht und den Service erleichtert. Durch die Möglichkeit, das Gewebe ein- und auszuklicken, ohne die Wickelwelle zu demontieren, gewährleistet dieses System eine schnellere Handhabung, eine längere Lebensdauer des Gewebes sowie eine höhere Ästhetik. Zudem beseitigt die optimierte Geometrie des Profils das Problem von Abdrücken im Gewebe, wodurch sich diese Lösung deutlich von klassischen ZIP-Screen-Rollladensystemen abhebt.

ZWEI ARTEN VON LED-BELEUCHTUNG IN DER FÜHRUNGSSCHIENE

Das integrierte ZIP-Screen-Rollladensystem kann mit einer durchgehenden LED-FLEX-Lichtlinie ausgestattet werden, die sowohl in der Revisionsklappe als auch in der großen ZIP-Führungsschiene platziert ist. Diese Lösung sorgt für einen homogenen Lichteffekt über die gesamte Höhe und Breite des Rollladens und eliminiert das Problem einer ungleichmäßigen Ausleuchtung des Gewebes. Die spezielle Konstruktion der ZIP-Führungsschiene ermöglicht eine ästhetische Integration der LED ohne zusätzliche Abdeckungen. Die Beleuchtung erhöht die Privatsphäre, indem sie die Transparenz des Gewebes reduziert, und das LED-Band ist in einem speziell vorgesehenen Bereich vor Beschädigungen geschützt. Im Gegensatz zu Standardlösungen, bei denen die LED nur im Rollladenkasten integriert ist, garantiert dieses System eine gleichmäßige Ausleuchtung des gesamten Gewebes und eine höhere Funktionalität.

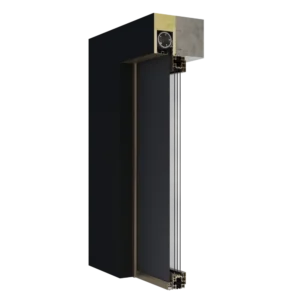

GROSSE ZIP-FÜHRUNGSSCHIENE

Die moderne große ZIP-Führungsschiene 130 mm x 40 mm sorgt für eine perfekte Anpassung an den Screen-Rollladenkasten und schafft ein harmonisches und ästhetisches Erscheinungsbild des Systems. Sie ist in zwei Varianten erhältlich – mit oder ohne LED-Beleuchtung – und ermöglicht so eine flexible Anpassung an die Bedürfnisse des Nutzers. Das CLICK-System eliminiert sichtbare Schrauben und beschleunigt Montage sowie Wartung. Eine spezielle Technik-Kammer ermöglicht das Verbergen der Verkabelung, die Installation von Batteriemotoren und Steuerzentralen. Das verdeckte ZIP-Schloss und eine durchgehende Abdeckung gewährleisten ein modernes Design, während präzise Profilverbindungen sichtbare Fugen eliminieren und die hohe Verarbeitungsqualität unterstreichen.

KLEINE ZIP-FÜHRUNGSSCHIENE

Die kleine ZIP-Führungsschiene ist eine kompakte und wirtschaftliche Lösung, die im Hinblick auf Ästhetik und Funktionalität entwickelt wurde. Die Führungsschiene ermöglicht eine breitere Ausnutzung der Nische und erlaubt die Integration mit Schiebeglassystemen, Fensterläden oder Vorhängen. Dank des CLICK-Systems erfolgt die Montage ohne sichtbare Schrauben, was ein modernes und einheitliches Erscheinungsbild gewährleistet. Das verdeckte ZIP-Schloss und präzise 45°-Verbindungen eliminieren sichtbare Spalten, während von innen verschraubte Abdeckkappen Haltbarkeit und Stabilität garantieren. Dies ist die ideale Lösung für Nutzer, die minimalistisches Design und flexible Einbaumöglichkeiten suchen.

ALUMINIUM-WICKELWELLE 100 mm

Die systemeigene Aluminium-Wickelwelle mit einem Durchmesser von 100 mm ist ein Schlüsselelement für großformatige Anlagen und gewährleistet hohe Festigkeit sowie einen stabilen Betrieb des Systems. Sie besteht aus der Aluminiumlegierung 6063 T6 und zeichnet sich durch eine geringe Durchbiegung aus. Dieses zentrale Bauteil der großformatigen Systeme bietet hervorragende Eigenschaften, insbesondere eine minimale Durchbiegung.

Dank der präzisen Ausführung ermöglicht die Welle ein gleichmäßiges und sanftes Aufwickeln des Gewebes. Eine spezielle Abstufung im Durchmesser reduziert Verformungen und sorgt für ein ästhetisches Erscheinungsbild sowie die Langlebigkeit des Materials. Zusätzlich verwendet das System ein Einsteckprofil für das Gewebe, das dessen Austausch ermöglicht, ohne die Welle aus dem Rollladen auszubauen – was die Wartung und Instandhaltung erheblich erleichtert.

UNTERLEISTE

Die beschwerende Unterleiste im ZIP-Screen-Rollladensystem ist eine innovative Lösung, die maximale Ästhetik, Langlebigkeit und einfache Montage gewährleistet. Durch die Integration mit dem ZIP-Schloss sowie den Einsatz eines PVC-Profils wird das Gewebe gleichmäßig gespannt, und ein eventueller Austausch gestaltet sich deutlich einfacher. Die Unterleiste ist nach dem Aufrollen des Gewebes vollständig im Kasten verborgen, was die Funktionalität erhöht und das Erscheinungsbild des gesamten Systems verbessert.

ZIP-EINSATZ

Der ZIP-Einsatz ist eine moderne Lösung im System, die maximale Stabilität und ein reibungsloses Führen des Gewebes gewährleistet. Dank der ZIP-Schloss-Technologie wird das Material gleichmäßig gespannt und über die gesamte Höhe sicher in den Führungsschienen gehalten, was Widerstandsfähigkeit gegen Windböen sowie das Fehlen von Spiel an den Kanten garantiert.

Der Einsatz besteht aus zwei Materialien mit unterschiedlicher Dichte – das eine sorgt für eine stabile Position in der Führungsschiene, während das andere, flexiblere, das Gewebe im Rollladen gleichmäßig spannt und so Wellenbildung und Falten verhindert.

DIE GRÖSSTEN ABMESSUNGEN AUF DEM MARKT

Das integrierte ZIP-Screen-Rollladensystem wurde speziell für die vollständige Integration mit den WIN CLIMATIC-Pergolen entwickelt und garantiert eine ästhetische, funktionale und vollständig verbaute Lösung ohne sichtbare Befestigungen oder geometrische Störungen. Die Systemkonstruktion ermöglicht die Realisierung von Verschattungen in beeindruckenden Dimensionen – die maximale Systembreite beträgt 7000 mm, die maximale Höhe 3400 mm, womit es zu den größten verfügbaren Lösungen in dieser Klasse gehört.

Der Kasten, die ZIP-Führungsschienen und die Unterleiste bilden eine kompakte und homogene Einheit, und alle Verbindungen werden in CLICK-Technologie ohne den Einsatz von Schrauben ausgeführt, was sich positiv auf die Ästhetik, Dichtheit sowie die Vereinfachung von Montage und Wartung auswirkt. Das System ermöglicht die Anwendung von vertikaler und horizontaler LED-Beleuchtung in den Führungsschienen sowie in der Revisionsklappe, wodurch eine gleichmäßige Hinterleuchtung des Gewebes erzielt wird. In Kombination mit der Pergola entsteht so ein einzigartiger visueller Effekt.

GLEITPROFIL

Das Gleitprofil des Gewebes mit integrierter Bürstendichtung ist ein Element im Inneren des Kastens, das für die Stabilisierung und das korrekte Führen des Gewebes verantwortlich ist. Seine Aufgabe besteht darin, das Material in der richtigen Position zu halten und so einen reibungslosen und störungsfreien Betrieb des Rollladens zu gewährleisten.

Durch den Einsatz der Bürstendichtung minimiert das Profil die Reibung des Gewebes, was es vor Beschädigungen schützt und seine Lebensdauer verlängert. Zusätzlich wirkt die Dichtung dämpfend, reduziert Geräusche und verbessert die Dichtheit des gesamten Systems. Diese Lösung garantiert einen präzisen und leisen Betrieb und trägt zum Komfort sowie zur Zuverlässigkeit des Verschattungssystems bei.

ABDECKKAPPEN DER UNTERLEISTEN

Die Abdeckkappen der Unterleiste wurden mit präzise geformten Nuten entwickelt, die die Linie der Bürstendichtungs-Tasche in der Leiste fortführen. Dadurch kann die Dichtung über die gesamte Breite des Rollladens – von Abdeckkappe zu Abdeckkappe – durchgehend geführt werden, was die Entstehung von Spalten an den Rändern der Unterleiste verhindert. Diese Lösung sorgt für eine bessere Abdichtung des Rollladens in geschlossener Position und reduziert das Eindringen von Licht, Insekten und Verschmutzungen.

TECHNIKBEREICH DER GROSSEN FÜHRUNGSSCHIENEN

Die große ZIP-Führungsschiene, die in adaptiven Screen-Rollladensystemen eingesetzt wird, wurde nicht nur für die Führung des Gewebes mit ZIP-Verschluss entwickelt, sondern auch als multifunktionales Bauteil mit einem sogenannten Technikbereich. Dieser Bereich stellt eine innere Arbeitskammer der Führungsschiene dar, die in der Produktions- oder Montagephase zur Verdeckung zusätzlicher Installationselemente genutzt werden kann, was die Gebrauchstauglichkeit und die ästhetischen Eigenschaften des Systems erheblich steigert.

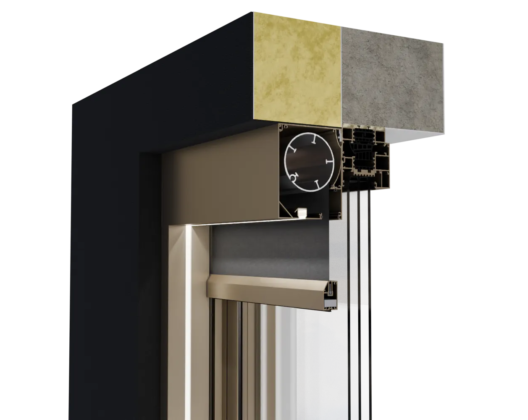

INTEGRATION MIT DEM SCHIEBEGLASSYSTEM WIN GLASS

Der Kasten des integrierten Systems wurde so konstruiert, dass eine sichere und stabile Montage der Führungsschiene des Schiebeglassystems WIN GLASS direkt an seiner oberen Fläche möglich ist. Die spezielle Konstruktion des Kastens eliminiert das Risiko einer Beschädigung des Rollladengewebes oder der Wickelwelle während der Montage und gewährleistet zugleich eine solide und ästhetische Verbindung beider Systeme.

INTEGRATION MIT DEM SCHIEBELÄDEN-SYSTEM WIN PANELS

Der Kasten des integrierten Systems wurde für die Montage der oberen Führungsschiene der Aluminium-Schiebeläden WIN PANELS direkt an seiner Oberseite angepasst.

Dank der entsprechend verstärkten Konstruktion ist ein stabiles und sicheres Anschrauben der Führungsschiene möglich, ohne dass das Rollladengewebe oder mechanische Elemente im Inneren des Kastens beschädigt werden. Diese Lösung ermöglicht eine ästhetische und funktionale Verbindung des integrierten Rollladensystems mit dem Schiebeladensystem und erhält die konstruktive sowie visuelle Einheit der gesamten Anlage.

ABDECKKAPPEN DER UNTERLEISTEN

Die Abdeckkappen der Unterleiste wurden mit präzise geformten Nuten entwickelt, die die Linie der Bürstendichtungs-Tasche in der Leiste fortsetzen. Dadurch kann die Dichtung über die gesamte Breite des Rollladens – von Abdeckkappe zu Abdeckkappe – durchgehend geführt werden, was die Entstehung von Spalten an den Rändern der Unterleiste verhindert. Diese Lösung sorgt für eine bessere Abdichtung des Rollladens in geschlossener Position und reduziert das Eindringen von Licht, Insekten und Verschmutzungen.

INTELLIGENTE STEUERUNG

Dank der Verwendung einer intelligenten Steuerzentrale besteht die Möglichkeit, die Pergola sowie das zusätzliche Zubehör über ein Smartphone oder Tablet von jedem Ort der Welt aus zu steuern.

PREMIUM-MATERIALIEN

Innovative Konstruktion mit Überdachung, gefertigt aus stranggepresstem Aluminium und Edelstahl. Die Profile bestehen aus hochwertigem, stranggepresstem Aluminium mit dicken und robusten Wandungen, verstärkt durch Kammern und Rippen.

BREITE FARBPALETTE DER KONSTRUKTION IM STANDARD

Wir bieten eine breite Farbpalette der Konstruktion im Standard! Die Konstruktion ist pulverbeschichtet in sieben Farben aus der Standardpalette WIN CLIMATIC S500. Darüber hinaus besteht die Möglichkeit einer Pulverbeschichtung in jeder beliebigen RAL-Farbe sowie in holzähnlichen Farbtönen.

KONFORMITÄT MIT DER CE-NORM

Unsere Produkte erfüllen die Anforderungen der Norm PN-EN 1090-1 bis PN-EN 1090-3, die vom Polnischen Komitee für Normung für Stahl- und Aluminiumkonstruktionen eingeführt wurde, was durch die Kennzeichnung der Produkte mit dem CE-Zeichen bestätigt wird.

TIGER COATINGS

Dank des Einsatzes duroplastischer Pulverbeschichtungen erhalten wir nahezu unbegrenzte Möglichkeiten der Oberflächenveredelung. In unseren Produkten verwenden wir ausschließlich Beschichtungen von TIGER COATINGS, die Langlebigkeit und kompromisslose Verarbeitungsqualität gewährleisten.

DAUERHAFTE LACKBESCHICHTUNG

Alle von uns hergestellten Konstruktionen verfügen über ein internationales Qualitätszertifikat für Lackbeschichtungen. Mit dem QUALICOAT-Siegel gekennzeichnete Produkte zeichnen sich durch hervorragende Eigenschaften aus, die von akkreditierten Prüflaboratorien bestätigt werden.

HOHE QUALITÄT DER PRODUKTHERSTELLUNG UND VERPACKUNG

Ein spezialisiertes Team sowie ein hochmoderner Maschinenpark ermöglichen es uns, die höchste Produktionsqualität zu erreichen. Jedes Produkt wird vor dem Versand von der Qualitätskontrolle sorgfältig auf Übereinstimmung mit der Bestellung und die Verarbeitungsqualität geprüft. Großen Wert legen wir auch auf die sorgfältige Verpackung und Sicherung der Ware für den Transport. Durch den Einsatz speziell angepasster Styroporformteile, Luftpolstermatten sowie stabiler, dicker Kartons können wir gewährleisten, dass die bestellte Ware in einwandfreiem Zustand bei Ihnen ankommt.

ZUSÄTZLICHES ZUBEHÖR

DISTANZSTÜCKE

DISTANZSTÜCKE

DISTANZSTÜCKE

DISTANZSTÜCKE Distanzstücke dienen zur Montage von Rollläden an Aluminiumfassaden. Sie können auch verwendet werden, um den Rollladen von der Fensterfläche oder der Gebäudewand abzusetzen.

FÜHRUNGSSCHIENEN-DISTANZ WS-DP-1

FÜHRUNGSSCHIENEN-DISTANZ WS-DP-2

FÜHRUNGSSCHIENEN-DISTANZ WS-DP-3

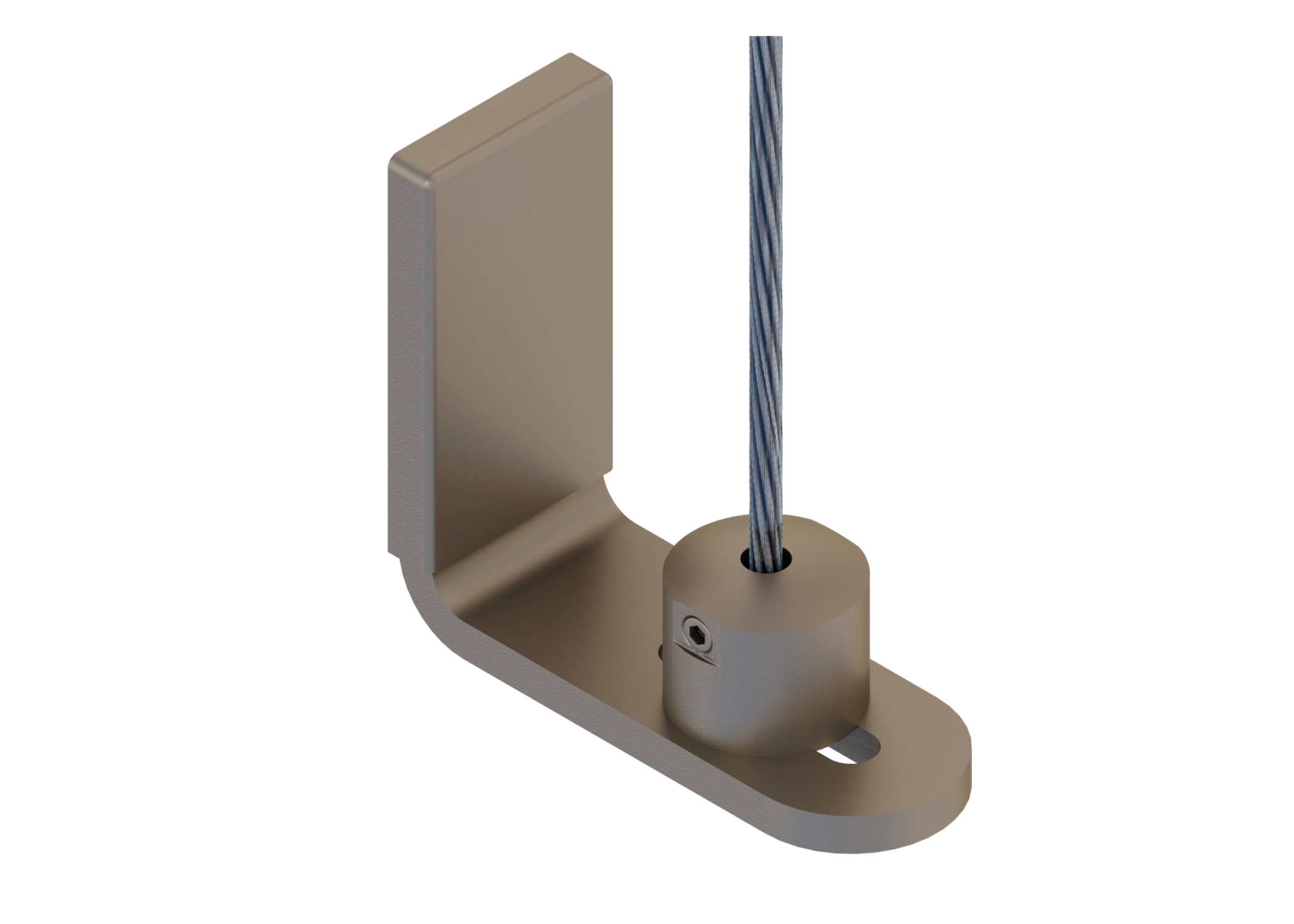

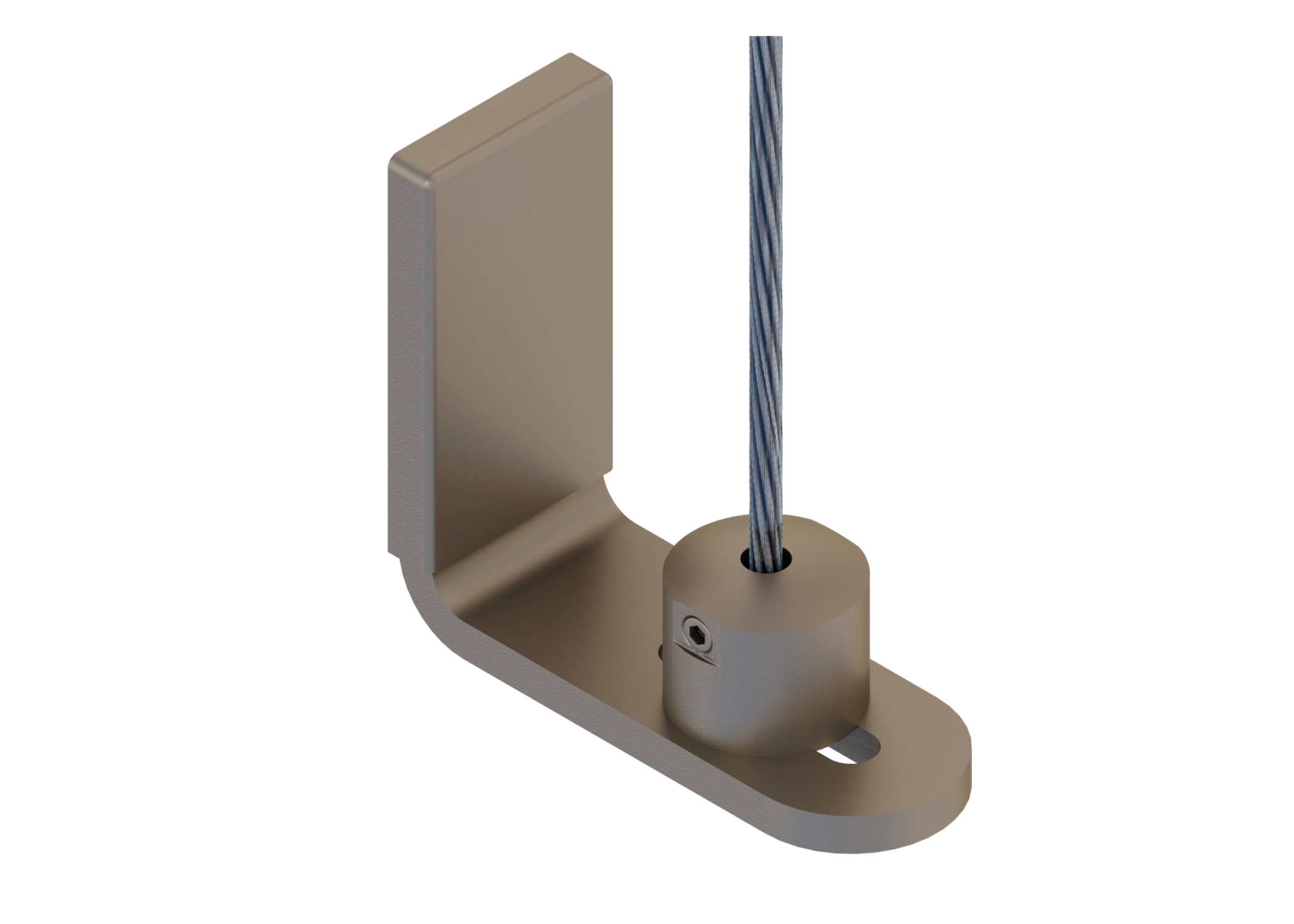

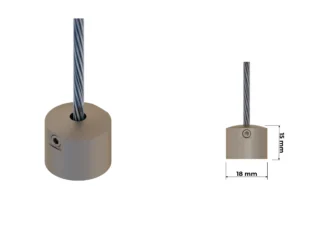

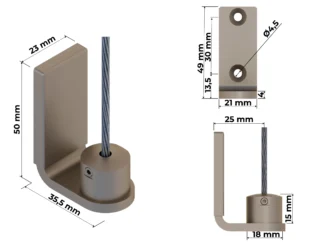

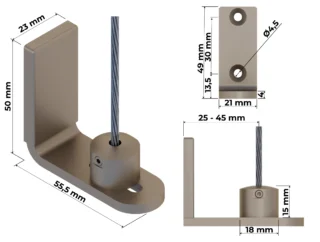

STAHLSEILHALTER

STAHLSEILHALTER

STAHLSEILHALTER

STAHLSEILHALTER STAHLSEILHALTER – BODENMONTAGE – FEST

STAHLSEILHALTER – WINKEL – FEST

STAHLSEILHALTER – WINKEL – VERSTELLBAR

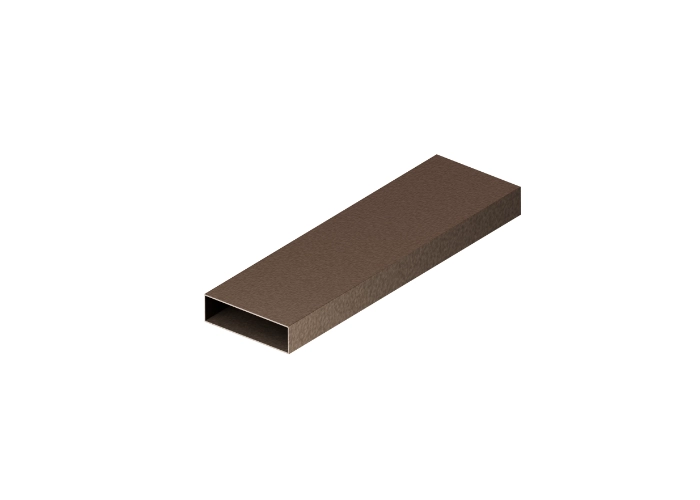

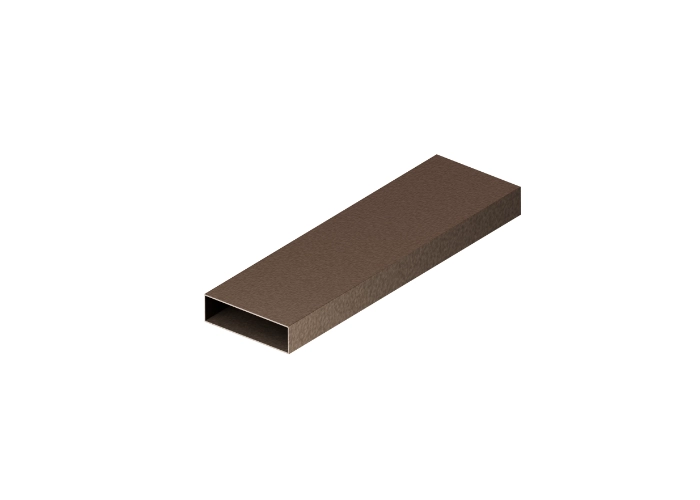

ERGÄNZUNGSPROFILE

ERGÄNZUNGSPROFILE

ERGÄNZUNGSPROFILE

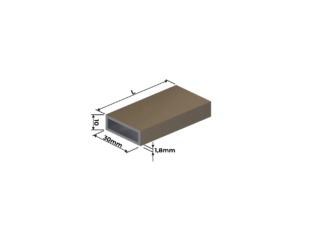

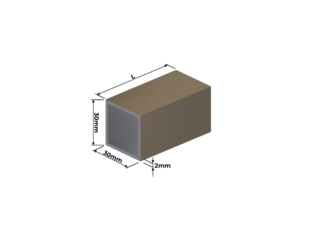

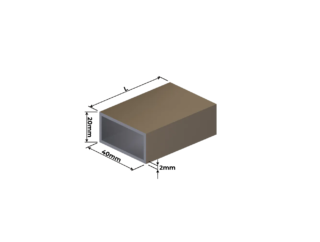

ERGÄNZUNGSPROFILE Zusätzliche Ergänzungsprofile, die bei speziellen Montagen hilfreich sind, bei denen z. B. zusätzliche Distanzierung oder eine Angleichung der Montagefläche erforderlich ist.

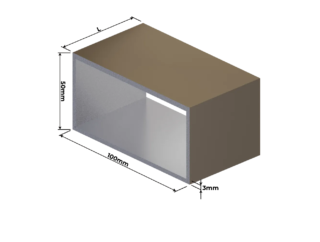

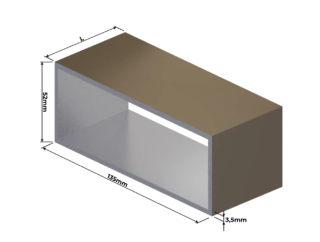

PROFIL SW-ALU 30x10x2

PROFIL SW-ALU 30x30x2

PROFIL SW-ALU 40x10x2

PROFIL SW-ALU-40x40x2

PROFIL SW-ALU 100x50x3

PROFIL SW-ALU 132x52x3,5

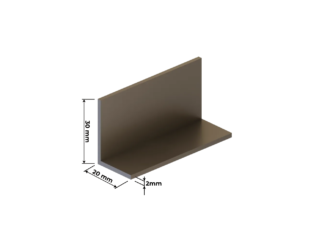

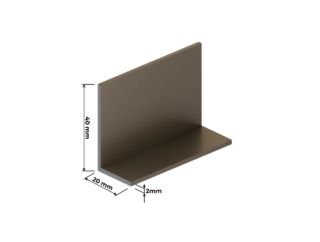

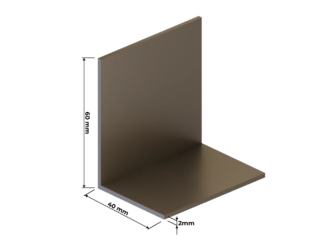

WINKELPROFILE

WINKELPROFILE

WINKELPROFILE

WINKELPROFILE Winkelprofile eignen sich hervorragend z. B. als Abdeckungen.

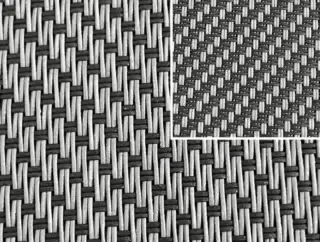

GEWEBEÖFFNUNG

FENSTER AUS CRISTAL-FOLIE

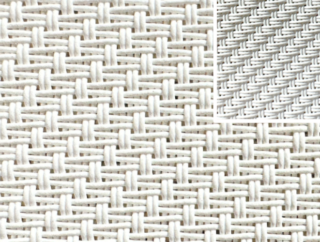

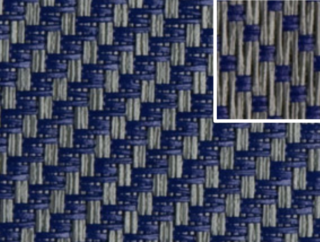

GEWEBEKOLLEKTIONEN

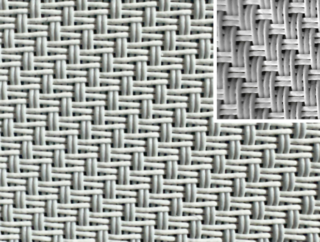

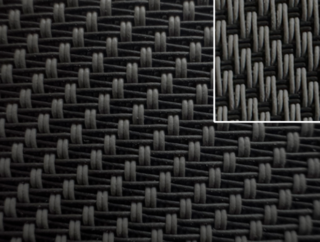

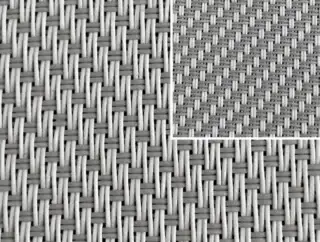

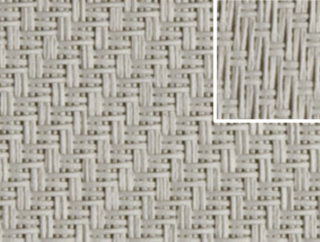

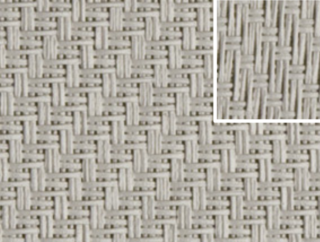

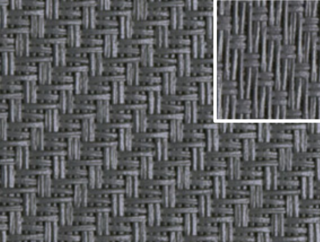

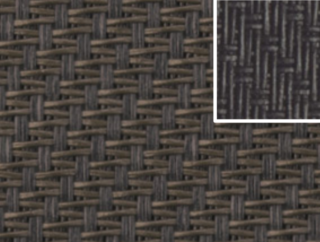

Kollektion WIN FABRIC mit einem Öffnungsfaktor von 5 %.

Gewebezusammensetzung: 42 % FG (Glasfaser), 58 % PVC

Gewebedicke: 0,78 mm

Brandschutzklassifizierung: EN 13773:2003 – KLASSE 1 NFPA701 – FR

Antibakterielle Beschichtung: ASTM E 2149

Verwendung: AUSSEN / INNEN

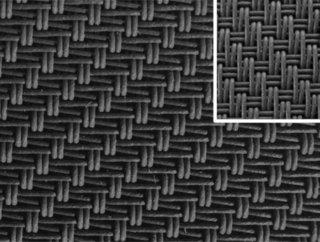

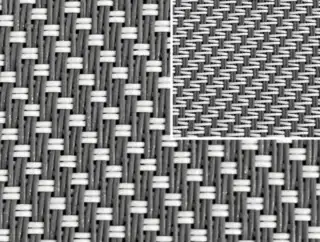

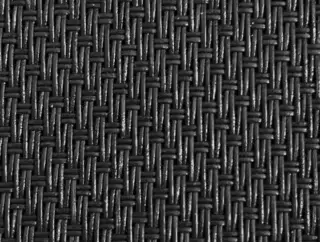

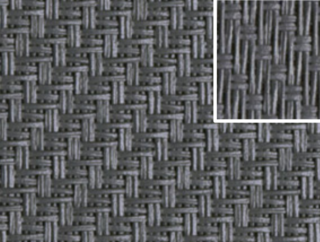

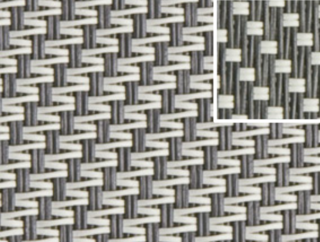

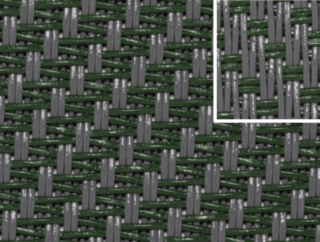

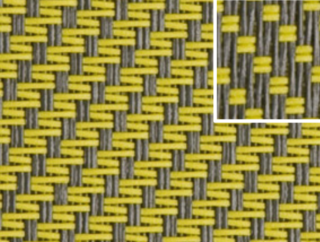

Kollektion von Stoffen SERGE FERRARI mit einem Öffnungsfaktor von 4 %.

Zusammensetzung des Stoffes: 30 % PES, 70 % PVC

Stoffdicke: 0,45 mm

Brandschutzklassifizierung: DIN 4102, Klasse B1, M1, B-s2, d0

Antibakterielle Beschichtung: ISO-2286-2 ISO 9001

Anwendung: AUSSEN / INNEN

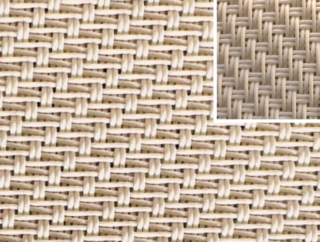

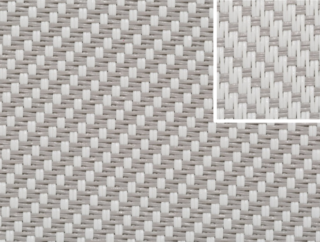

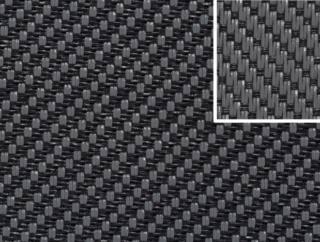

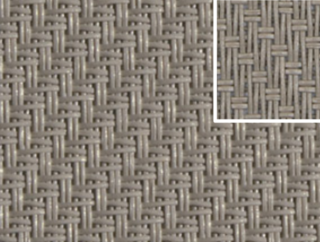

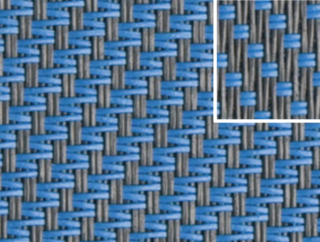

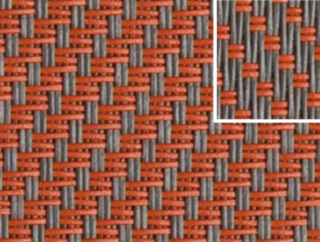

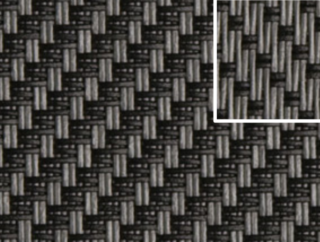

Kollektion von Stoffen SERGE FERRARI mit einem Öffnungsfaktor von 5 %.

Zusammensetzung des Stoffes: 42 % FG (Glasfaser), 58 % PVC

Stoffdicke: 0,73 mm

Brandschutzklassifizierung: B1/DIN 4102-1 M1/NF P 92-507 C-S3, D0

Antibakterielle Beschichtung: KEINE

Anwendung: AUSSEN / INNEN

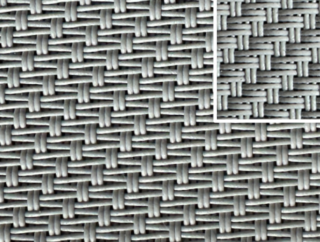

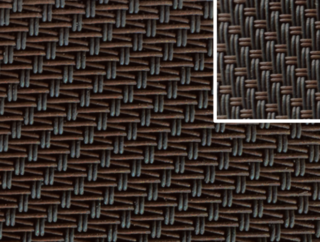

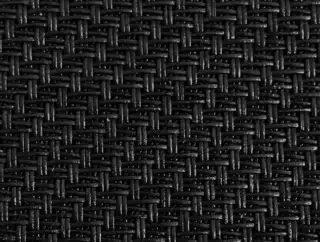

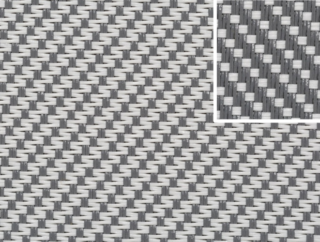

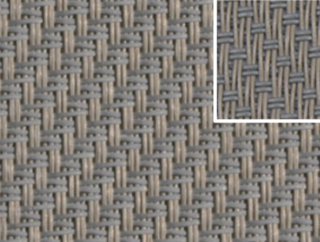

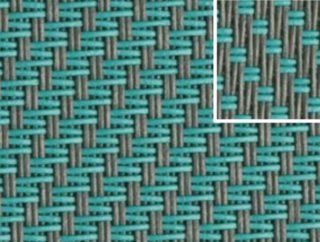

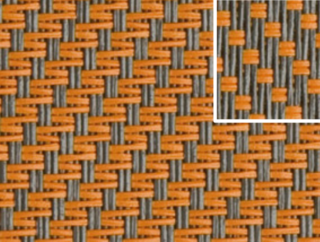

Kollektion von Stoffen SERGE FERRARI mit einem Öffnungsfaktor von 14 %.

Zusammensetzung des Stoffes: 30 % PES, 70 % PVC

Stoffdicke: 0,45 mm

Brandschutzklassifizierung: DIN 4102, Klasse B1, M1, B-s2, d0

Antibakterielle Beschichtung: ISO-2286-2 ISO 9001

Anwendung: AUSSEN / INNEN

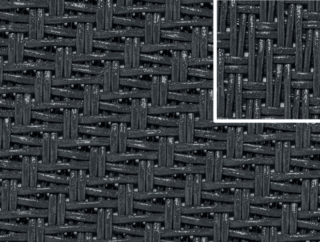

Kollektion von Stoffen COPACO SERGE 600 mit einem Öffnungsfaktor von 1 %.

Zusammensetzung des Stoffes: 42 % FG (Glasfaser), 58 % PVC

Stoffdicke: 0,78 mm

Brandschutzklassifizierung: B1/DIN 4102-1 M1/NF P 92-507 C-S3, D0

Antibakterielle Beschichtung: KEINE

Anwendung: AUSSEN / INNEN

Kollektion von Stoffen COPACO SERGE 600 mit einem Öffnungsfaktor von 5 %.

Zusammensetzung des Stoffes: 42 % FG (Glasfaser), 58 % PVC

Stoffdicke: 0,74 mm

Brandschutzklassifizierung: UNE-EN 13501-1:2007 C-s3,d0 NF P92-503 M1 DIN 4102 B1

Antibakterielle Beschichtung: KEINE

Anwendung: AUSSEN / INNEN

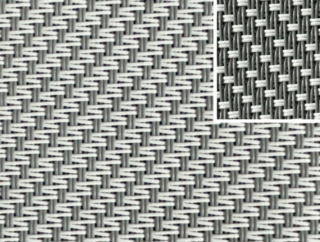

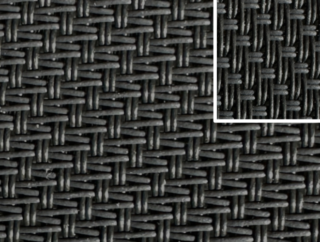

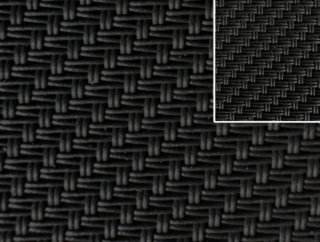

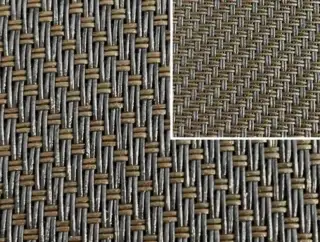

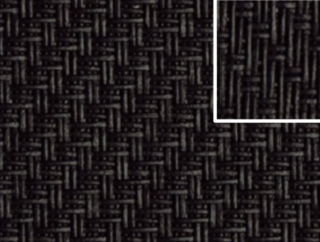

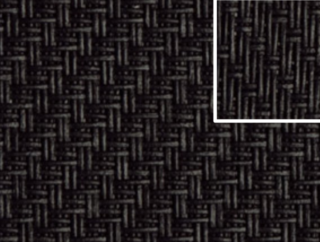

Kollektion von Stoffen COPACO SERGE BLACKOUT mit einem Öffnungsfaktor von 0 %.

Zusammensetzung des Stoffes: 33 % FG (Glasfaser), 47 % PVC, 20 % PVC-Laminat

Stoffdicke: 0,73 mm

Brandschutzklassifizierung: NF P92-503 M2 UNI 9177 Klasse 1

Antibakterielle Beschichtung: KEINE

Anwendung: AUSSEN / INNEN

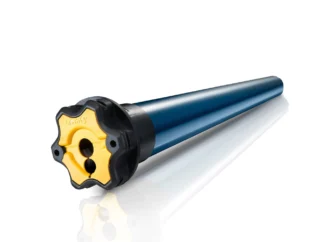

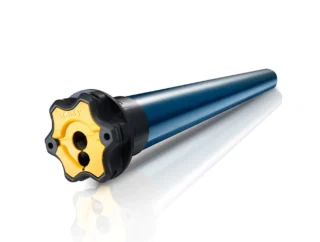

ANTRIEBE UND STEUERUNG

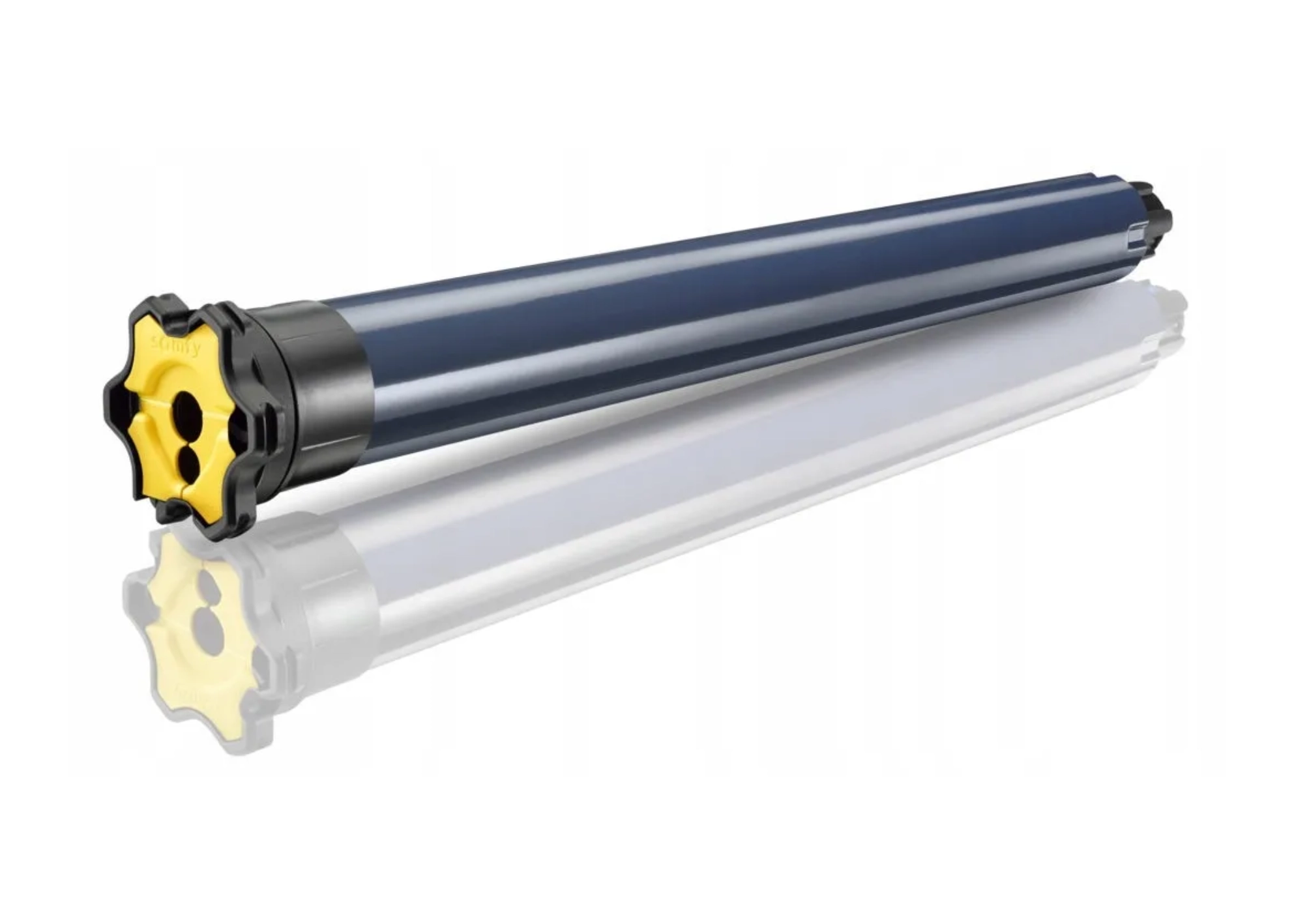

Antriebe der Serie WIN CONTROL sind die technologisch fortschrittlichsten Antriebe auf dem Markt.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: JA

Standard-Hinderniserkennung: JA

PLUG&PLAY-Kabel: JA (weiß, Länge 2,5 m)

Zusätzliches optionales PLUG&PLAY-Kabel: JA (schwarz, Länge 5 m oder 10 m)

Garantiezeitraum: 5 Jahre

Antriebe der Serie SOMFY

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

Endlagen: mechanisch/elektronisch

Erweiterte Hinderniserkennung mit Einstellung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: JA (nur Maestria) / NEIN (alle übrigen Antriebe)

PLUG&PLAY-Kabel: JA (weiß, Länge 2,5 m oder 3 m)

Zusätzliches optionales PLUG&PLAY-Kabel: JA (schwarz, Länge 5 m oder 10 m)

Zusätzliches optionales PLUG&PLAY-Kabel: JA (weiß oder schwarz, Länge 5 m oder 10 m)

Garantiezeitraum: 5 Jahre

2-Wege-Funkantriebe der Serie WIN CONTROL. Motoren mit Funksteuerung und Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: JA

Frequenz: 868 MHz

Steuerung: Wandschalter, Handsender, Smartphone / mit Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / mit Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: JA

Standard-Hinderniserkennung: JA

Unterstützung für Wettersensoren: JA

PLUG&PLAY-Kabel: JA (weiß, Länge 3 m)

Zusätzliches PLUG&PLAY-Kabel: JA (schwarz, Länge 5 m oder 10 m)

Garantiezeitraum: 5 Jahre

2-Wege-Funkantriebe der Serie SOMFY. Motoren mit Funksteuerung und Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: NEIN

Frequenz: 868 MHz

Steuerung: Wandschalter, Handsender, Smartphone / mit Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / mit Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung: JA / NEIN

Unterstützung für Wettersensoren: JA / NEIN

PLUG&PLAY-Kabel: JA (weiß, Länge 3 m)

Zusätzliches PLUG&PLAY-Kabel: JA (weiß oder schwarz, Länge 5 m oder 10 m)

Garantiezeitraum: 5 Jahre

1-Wege-Funkantriebe der Serie SOMFY. Motoren mit Funksteuerung ohne Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: NEIN

Frequenz: 433 MHz

Steuerung: Wandschalter, Handsender, Smartphone / ohne Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / ohne Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung: NEIN

Unterstützung für Wettersensoren: JA

PLUG&PLAY-Kabel: JA (weiß, Länge 3 m oder 5 m)

PLUG&PLAY-Kabel: JA (weiß oder schwarz, Länge 5 m oder 10 m)

Garantiezeitraum: 5 Jahre

1-Wege-Funkantriebe der Serie YOODA. Motoren mit Funksteuerung ohne Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: NEIN

Frequenz: 433 MHz

Steuerung: Wandschalter, Handsender, Smartphone / ohne Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / ohne Rückmeldesignal

Endlagen: mechanisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung: NEIN

Unterstützung für Wettersensoren: JA

PLUG&PLAY-Kabel: NEIN

Garantiezeitraum: 5 Jahre

Solaranlage mit integriertem Akku und Solarpanel. Antriebe mit Funksteuerung und Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: JA

Frequenz: 868 MHz

Steuerung: Wandschalter, Handsender, Smartphone / mit Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / mit Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: JA

Standard-Hinderniserkennung: NEIN

Unterstützung für Wettersensoren: JA

PLUG&PLAY-Kabel: JA (schwarz, Länge 0,3 m)

Zusätzliches PLUG&PLAY-Kabel: JA (schwarz, Länge 5 m oder 10 m)

Sanftanlauf / Sanftstopp: JA

Integrierte Batterie im Antrieb: JA

Solarmodul montierbar mit Nieten oder Befestigungsdübeln: JA

Solarmodul montierbar mit 3M-Klebeband: JA

Garantiezeitraum: 5 Jahre

Solaranlage mit integriertem Akku und Solarpanel. Antriebe mit Funksteuerung und Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: NEIN

Frequenz: 868 MHz

Steuerung: Wandschalter, Handsender, Smartphone / mit Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / mit Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung: JA

Unterstützung für Wettersensoren: JA

PLUG&PLAY-Kabel: JA (schwarz, Länge 0,25 m)

Zusätzliches PLUG&PLAY-Kabel: JA (schwarz, Länge 5 m oder 10 m)

Integrierte Batterie im Antrieb: NEIN (Batterie separat außerhalb des Antriebs)

Garantiezeitraum: 5 Jahre

Solaranlage SOMFY mit Akku ohne Gehäuse und Solarpanel. Antriebe mit Funksteuerung und Rückmeldesignal von der Jalousie.

Bestimmung: ADAPTIVES SYSTEM, INTEGRIERTES SYSTEM, UNTERPUTZSYSTEM

ZIGBEE 3.0: NEIN

Frequenz: 433 MHz

Steuerung: Wandschalter, Handsender, Smartphone / mit Rückmeldesignal

Möglichkeit der intelligenten Steuerung: JA / mit Rückmeldesignal

Endlagen: elektronisch

Erweiterte Hinderniserkennung, die in SCREEN-Rollläden korrekt funktioniert: NEIN

Standard-Hinderniserkennung: JA / NEIN

Unterstützung für Wettersensoren: JA / NEIN

PLUG&PLAY-Kabel: NEIN

Standardkabel: JA (Länge 1 m)

Integrierte Batterie: NEIN (Batterie separat außerhalb des Antriebs)

Garantiezeitraum: 5 Jahre

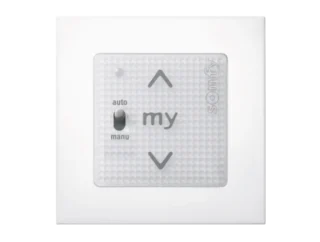

STEUERUNG

FUNKGESTEUERTE BEDIENUNG

FUNKGESTEUERTE BEDIENUNG

FUNKGESTEUERTE BEDIENUNG

FUNKGESTEUERTE BEDIENUNG WÄHLEN SIE DIE IDEALE STEUERUNG FÜR WIN SCREEN ROLLLÄDEN

Umfangreiches Angebot an Funksteuerungen für WIN SCREEN Rollläden.

Zur Auswahl stehen Wandschalter und Handsender in verschiedenen Farben und Ausführungen.

STEUERUNG WIN CONTROL

STEUERUNG SOMFY

STEUERUNG YOODA

INTELLIGENTE STEUERUNG

INTELLIGENTE STEUERUNG

INTELLIGENTE STEUERUNG

INTELLIGENTE STEUERUNG WLAN-Zentrale – warum lohnt es sich?

Intelligente Zentrale mit integriertem WLAN-Interface zur Steuerung der Zentralen über Smartphone oder Tablet mittels App und mit der Möglichkeit der Fernsteuerung über das Internet.

Sie bietet eine einfache Erstellung von Szenarien und die Programmierung eines Wochen-Timers. Die WLAN-Zentrale ermöglicht den Anschluss und die Steuerung von Geräten über mehrere Smartphones oder Tablets gleichzeitig und bietet dem Nutzer zudem die Möglichkeit der Sprachsteuerung über Google Home oder Amazon Assistant.

Intelligente WIN CONTROL Zentrale mit ZIGBEE 3.0

Der neueste Standard für drahtlose Kommunikation, entwickelt für Smart-Home-Geräte, Gebäudeautomation und industrielle Anwendungen. Er gewährleistet eine zuverlässige und sichere Kommunikation zwischen verschiedenen Geräten.

VERDRAHTETE STEUERUNG

VERDRAHTETE STEUERUNG

VERDRAHTETE STEUERUNG

VERDRAHTETE STEUERUNG WÄHLEN SIE DIE IDEALE STEUERUNG FÜR WIN SCREEN ROLLLÄDEN

Umfangreiches Angebot an kabelgebundenen Steuerungen für WIN SCREEN Rollläden.

Zur Auswahl stehen Wandschalter, Steuerzentralen und Zeitschaltuhren in verschiedenen Farben und Ausführungen.

STEUERUNG SOMFY